Pre-crosslinked gel granulate for profile control and polymer flooding as well as preparation method and application of pre-crosslinked gel granulates

A gel particle, pre-crosslinking technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of difficult on-site implementation, shear thinning, large loss of effective viscosity, etc., and improve oil recovery. yield, control cycle time, avoid shear thinning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] formula

[0041]

[0042]

[0043] The mass percent concentration of the monomer (AA+AM) is 30g / 142.66=21%. The ratio of unstable cross-linking agent to composite monomer is 1:200.

[0044] Polymerization process

[0045] Add acrylamide, acrylic acid and polyethylene glycol dimethacrylate into 110 g of water to fully dissolve. Add NaCO after dissolving 3 Neutralize the solution. Then add TMEDA, urea, ammonia and sodium hydroxide. The solution was purged with nitrogen gas for 30 min, and then K was added to the solution 2 S 2 o 8 , The obtained solution was purged with nitrogen again for 10 minutes, and then placed in a 10°C incubator. First evacuate to -10KPa for 30 minutes to remove oxygen in the air, then maintain the vacuum state while injecting pure nitrogen to remove oxygen in the solution, start the polymerization process, and completely gel after 12 hours to obtain bulk gel.

[0046] After forming the gel, put the bulk gel in distilled water, soak ...

Embodiment 2

[0053] formula

[0054]

[0055] The mass percent concentration of the monomer (AA+AM) is 15g / 127.4675=11.76%

[0056] The ratio of unstable crosslinking agent to composite monomer is 1:400

[0057] Polymerization process

[0058] Add acrylamide, acrylic acid and polyethylene glycol dimethacrylate to fully dissolve in water. Add NaCO after dissolving 3 Neutralize the solution. Then add TMEDA, urea, ammonia and sodium hydroxide. The solution was purged with nitrogen gas for 30 min, and then K was added to the solution 2 S 2 o 8, The obtained solution was purged with nitrogen again for 10 minutes, and then placed in a 10°C incubator. First evacuate to -10KPa for 30 minutes to remove the oxygen in the air, then maintain the vacuum state and inject pure nitrogen at the same time to remove the oxygen in the solution and start the polymerization process. After 13 hours, the gel is completely formed and the bulk gel is obtained.

[0059] After forming the gel, put the bul...

Embodiment 3

[0064] formula

[0065]

[0066] The mass percent concentration of the monomer (AA+AM+AMPS) is 30 / 136.54=22.0%

[0067] The ratio of unstable crosslinking agent to composite monomer is 1:1000

[0068] Polymerization process

[0069] With embodiment 1.

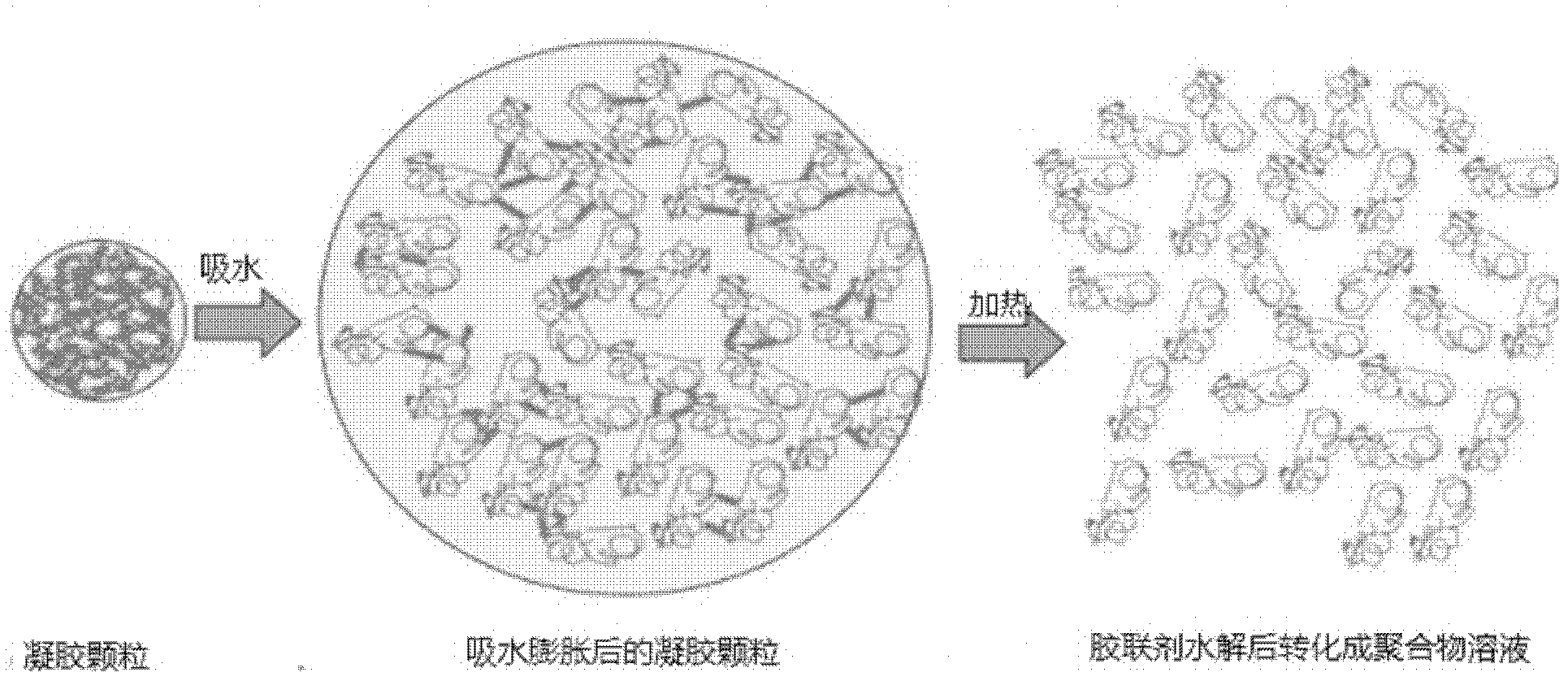

[0070] Hydrolysis test

[0071] The hydrolysis experimental procedure is the same as in Example 1.

[0072] At 80°C, it takes 6 days for the pre-crosslinked gel particles to be hydrolyzed into a polymer solution, and the viscosity of the polymer solution obtained after hydrolysis is 100cp; at 60°C, it takes about 35 days for complete hydrolysis, and the viscosity of the obtained polymer solution is 160cp. The viscosity of the resulting polymer solution was 190 cp for hydrolysis after 150 days at 45°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com