Silica corundum brick

A technology of silicon corundum bricks and white corundum powder, applied in the field of refractory materials, can solve the problems of restricting the scope of use, shortening the service life, wasting resources, etc., and achieving the effects of significant economic and social benefits, high utilization rate of raw materials, and easy operation and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

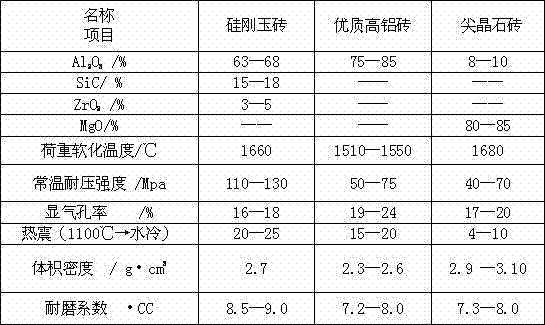

Image

Examples

Embodiment 1

[0018] The present invention consists of the following components by weight percentage:

[0019] Al 2 o 3 Bauxite clinker with mass content > 87%, 4mm ≥ particle size > 2mm 15%;

[0020] Al 2 o 3 Mass content > 87%, bauxite clinker with 2mm ≥ particle size > 1mm 39%;

[0021] 3% zircon sand powder passed through a 200 mesh sieve;

[0022] SiC mass content > 97%, 17% of silicon carbide powder passed through 200 mesh sieve;

[0023] 10% fused white corundum powder passed through a 300-mesh sieve;

[0024] 5% sialon powder passed through a 300-mesh sieve;

[0025] Kyanite powder 4% through 200 mesh sieve;

[0026] Cross 7% of the soft refractory clay of 200 mesh sieves, the total amount is 100% as basic raw material, then add binding agent and make, and described binding agent is sulfurous acid pulp waste liquid, and concentration is 1.18g / cm 3 , the addition amount is 4.5% of the basic raw material weight;

[0027] Among them, Al 2 o 3 Bauxite clinker and Al with mas...

Embodiment 2

[0029] The present invention consists of the following components by weight percentage:

[0030] Al 2 o 3 Mass content > 87%, bauxite clinker with 4mm ≥ particle size > 2mm 17%;

[0031] Al 2 o 3 Mass content > 87%, bauxite clinker with 2mm ≥ particle size > 1mm 35%;

[0032] 4% zircon sand powder passed through a 200-mesh sieve;

[0033] SiC mass content > 97%, 16% silicon carbide powder passed through 200 mesh sieve;

[0034] 11% fused white corundum powder passed through a 300-mesh sieve;

[0035] 6% sialon powder passed through a 300-mesh sieve;

[0036] Kyanite powder 5% through 200 mesh sieve;

[0037] Cross 200 mesh sieves of soft refractory clay 6%, the total amount is 100% as basic raw material, then add binding agent to make, described binding agent is sulfurous acid pulp waste liquid, concentration is 1.2g / cm 3 , the addition is 4% of the basic raw material weight;

[0038] Among them, Al 2 o 3 Bauxite clinker and Al with mass content > 87%, 4mm ≥ partic...

Embodiment 3

[0040] The present invention consists of the following components by weight percentage:

[0041] Al 2 o 3 Mass content > 87%, bauxite clinker with 4mm ≥ particle size > 2mm 16%;

[0042] Al 2 o 3 Mass content > 87%, bauxite clinker with 2mm ≥ particle size > 1mm 35%;

[0043] 3% zircon sand powder passed through a 200 mesh sieve;

[0044] SiC mass content > 97%, 15% silicon carbide powder passed through 200 mesh sieve;

[0045] 12% of fused white corundum powder passed through a 300-mesh sieve;

[0046] 7% of sialon powder passed through a 300-mesh sieve;

[0047] Kyanite powder 4% through 200 mesh sieve;

[0048] Cross 8% of the soft refractory clay of 200 mesh sieves, the total amount is 100% as basic raw material, then add binding agent and make, and described binding agent is sulfurous acid pulp waste liquid, and concentration is 1.25g / cm 3 , the addition amount is 4.4% of the basic raw material weight;

[0049] Among them, Al 2 o 3 Bauxite clinker and Al with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com