High-strength high-purity basalt continuous fiber production technique

A continuous fiber and production process technology, applied in the field of inorganic non-metallic fiber production process, can solve the problems of fiber strength, chemical stability, thermal stability and other basic performance reduction, affecting the quality of basalt continuous fiber, etc., to achieve product quality improvement, Increased yarn yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

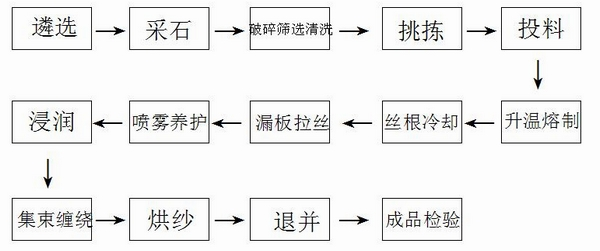

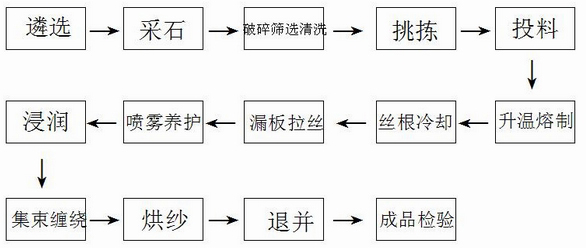

[0016] figure 1 Medium and high-strength pure basalt continuous fiber production process, the main process consists of selection, quarrying, crushing, screening and cleaning, picking, feeding, heating and melting, root cooling, bushing drawing, spray curing, infiltration, cluster winding, drying, retreating And the finished product inspection, the selection is based on a natural basalt as a single component raw material, the natural basalt is selected with uniform crystal structure, high purity, basic oxide acid modulus: MK=(Sio2+Al2o3) / (Cao +Mgo), the basic oxide acid modulus is kept in the range of 4.3-5.8, while Fe2o3+Feo is controlled between 8-15%.

[0017] According to the high-strength pure basalt continuous fiber production process, the quarrying is to mine the selected basalt ore by stripping and excavating the selected basalt ore according to the selected ore point and its layer position; The crushing, screening and cleaning are to crush and screen the mined basalt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com