A preparation method of reconstituted tobacco flakes

A technology for reconstituting tobacco and thin slices, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of large equipment site investment, insufficient curling degree of slices, complicated production process, etc., and achieves high utilization rate, good product stability, filling and filling. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

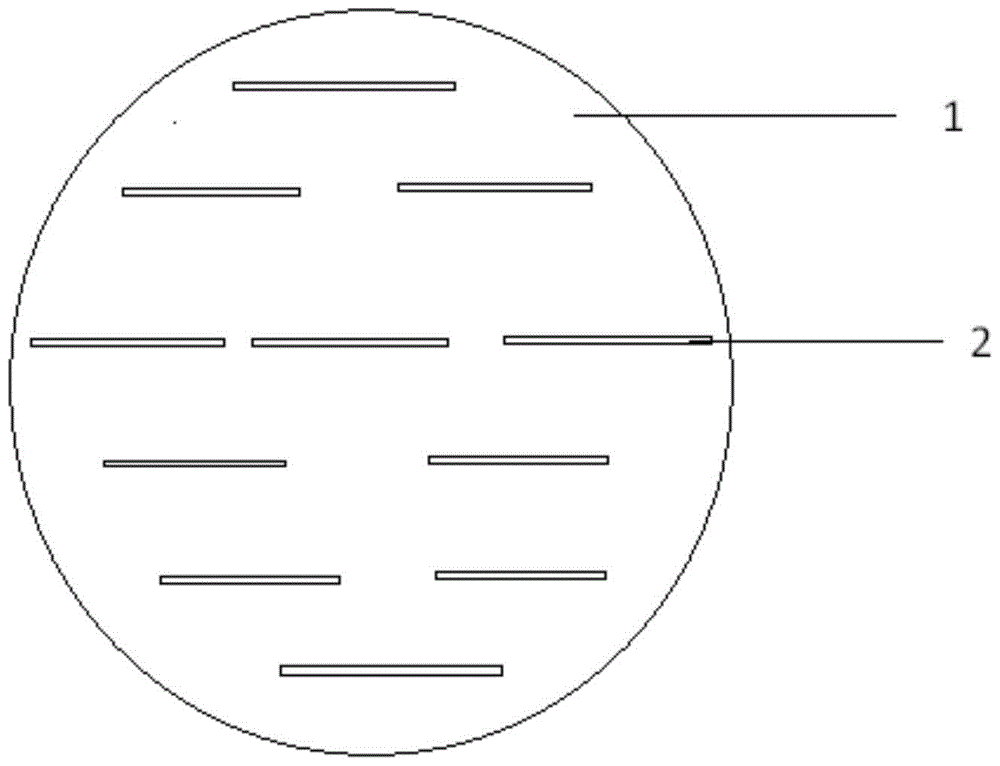

Image

Examples

Embodiment 1

[0033] Stir and mix 100 parts of 40-80 mesh tobacco powder fragments and 3 parts of gum arabic; dissolve 2 parts of propylene glycol in 15 parts of water and spray on the above-mentioned tobacco powder powder containing gum arabic, and stir evenly to form a semi-moist powder mixture; Put the wet material into a twin-screw extruder with a screw length-to-diameter ratio of 12, a helix angle of 13°, and a compression ratio of 4, and extrude it through 12 flat holes of 0.2mm*1mm on the die, and Cut it into short filaments with a length of 10-30mm by using an automatic cutting machine, dry them in a microwave, and then balance the moisture content to 8% to obtain a thin slice A.

Embodiment 2

[0035] Stir and mix 100 parts of 60-100 mesh tobacco powder and 5 parts of polyethylene hot-melt adhesive powder evenly; dissolve 3 parts of xylitol in 20 parts of water and spray on the above-mentioned smoke powder containing polyethylene hot-melt adhesive , stir evenly to form a semi-moist powder mixture; add the wet material into a twin-screw extruder with a screw length-to-diameter ratio of 15, a helix angle of 11°, and a compression ratio of 2.5, and control the temperature in the extrusion chamber to about 120°C Melt the hot melt adhesive and bond with the powder, extrude through 10 flat holes of 0.2mm*1mm on the die, and use an automatic cutting machine to cut it into 10-30mm long short filaments, microwave them After drying, balance the moisture content to 6% to obtain flake sample B.

Embodiment 3

[0037] Stir and mix 80 parts of 100-140 mesh tobacco powder powder, 20 parts of bagasse powder, 5 parts of starch, and 5 parts of sodium alginate; dissolve 3 parts of maltooligosaccharide alcohol in 20 parts of water and spray on the above-mentioned mixture powder In the process, stir evenly to form a semi-moist powder mixture; add the wet material into the twin-screw extruder with a screw length-to-diameter ratio of 18, a helix angle of 20°, and a compression ratio of 6, and pass through 15 0.15mm *1.5mm flat holes are extruded and cut into 10-30mm short filaments by an automatic cutting machine. After microwave drying, the moisture content is balanced to 8% to obtain thin slice C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com