An energy-saving multi-stage leak-board glass kiln device

A glass kiln and bushing technology, used in glass production, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of glass liquid residue, poor fiber quality, and shorten the service life of the kiln, and achieve the reduction of impurity content and product performance. Stable, product performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

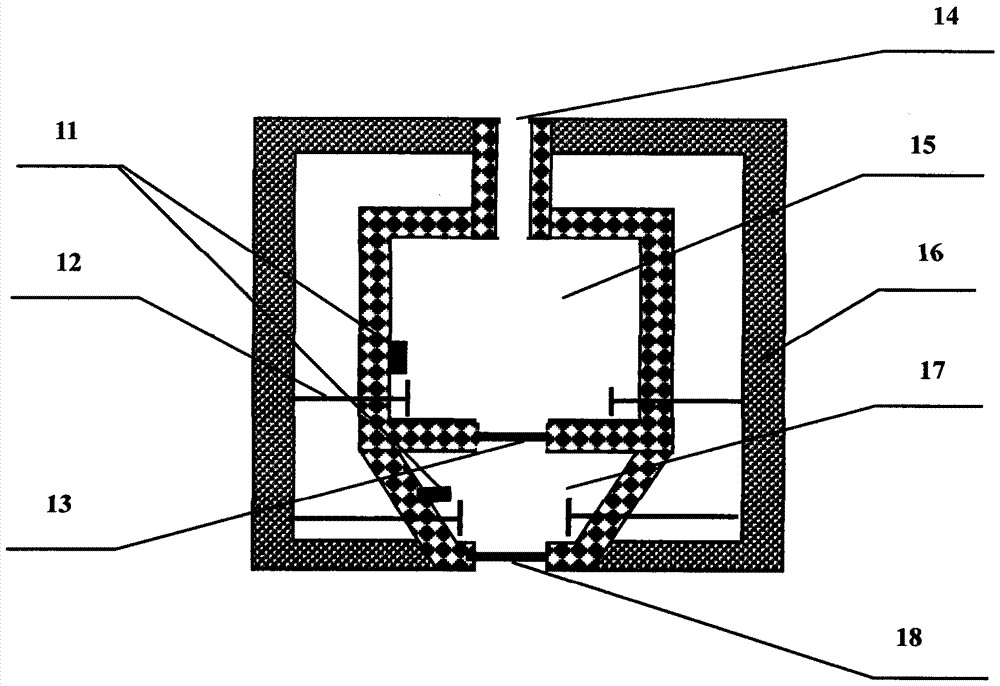

[0024] An energy-saving multi-stage drainboard glass kiln device, including a melting chamber, a heat preservation chamber, a shell layer and a temperature control system, characterized in that a first-stage drainboard is installed in the center of the bottom of the melting chamber, and the heat preservation chamber is located at the bottom of the melting chamber Directly below, a secondary leakage plate is installed in the center of the bottom of the heat preservation chamber, and there is a layer of air between the shell layer, the melting chamber and the heat preservation chamber.

[0025] The inner diameter of the melting chamber is 30cm and the height is 20cm; the inner diameter of the lower bottom of the heat preservation chamber is 30cm, the inner diameter of the upper bottom is 15cm, and the height is 17cm.

[0026] Both the primary leak plate and the secondary leak plate are rectangular, wherein the hole diameter of the primary leak plate is 1.2 times that of the secon...

Embodiment 2

[0032] An energy-saving multi-stage drainboard glass kiln device, including a melting chamber, a heat preservation chamber, a shell layer and a temperature control system, characterized in that a first-stage drainboard is installed in the center of the bottom of the melting chamber, and the heat preservation chamber is located at the bottom of the melting chamber Directly below, a secondary leakage plate is installed in the center of the bottom of the heat preservation chamber, and there is a layer of air between the shell layer, the melting chamber and the heat preservation chamber.

[0033] The inner diameter of the melting chamber is 70cm and the height is 35cm; the inner diameter of the lower bottom of the heat preservation chamber is 70cm, the inner diameter of the upper bottom is 40cm, and the height is 28cm.

[0034] Both the primary leak plate and the secondary leak plate are rectangular, wherein the hole diameter of the primary leak plate is 1.7 times that of the secon...

Embodiment 3

[0040] An energy-saving multi-stage drainboard glass kiln device, including a melting chamber, a heat preservation chamber, a shell layer and a temperature control system, characterized in that a first-stage drainboard is installed in the center of the bottom of the melting chamber, and the heat preservation chamber is located at the bottom of the melting chamber Directly below, a secondary leakage plate is installed in the center of the bottom of the heat preservation chamber, and there is a layer of air between the shell layer, the melting chamber and the heat preservation chamber.

[0041] The inner diameter of the melting chamber is 120cm and the height is 50cm; the inner diameter of the lower bottom of the heat preservation chamber is 120cm, the inner diameter of the upper bottom is 60cm, and the height is 38cm.

[0042] Both the primary leak plate and the secondary leak plate are rectangular, wherein the hole diameter of the primary leak plate is twice that of the seconda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com