Slow-release carbon source material using sodium alginate as base material and preparation method thereof

A sodium alginate and slow-release carbon source technology, applied in the field of water treatment, can solve the problems of poor denitrification and denitrification effects, and achieve the effects of overcoming the decline in microbial metabolic function, strong operability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

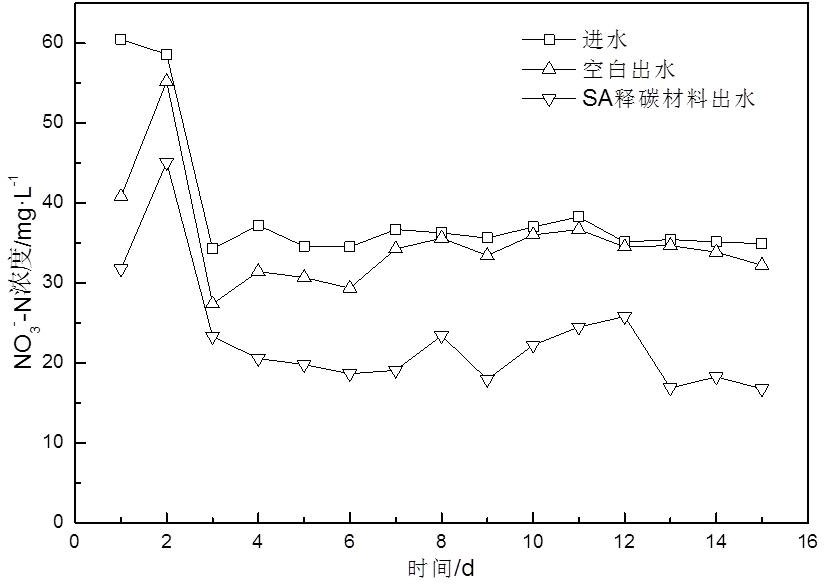

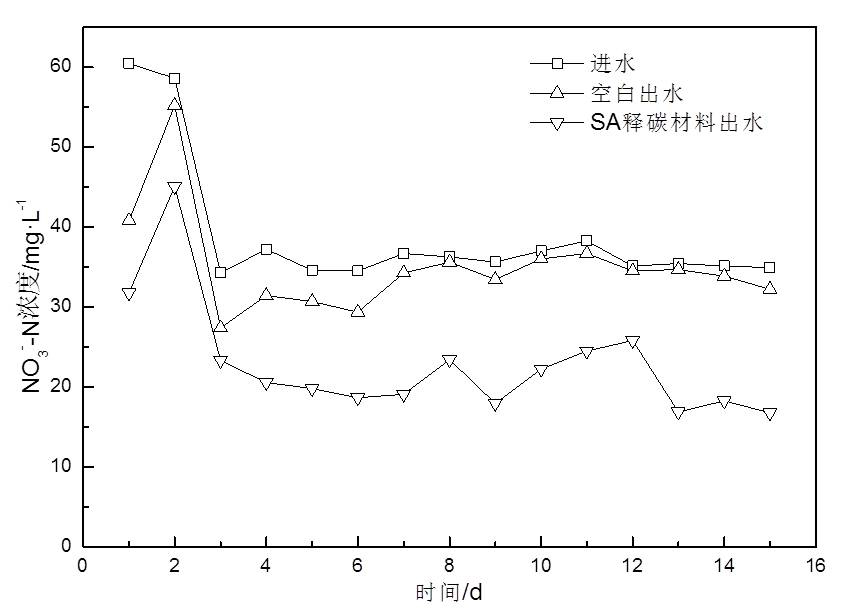

Embodiment 1

[0027] In this example, the preparation method of the slow-release carbon source material with sodium alginate as the base material is as follows: Weigh 16 g of sodium alginate and 20 g of starch and dissolve them in 400 mL of pure water to prepare a mixture containing 4% sodium alginate, A mixed solution of starch with a mass volume concentration of 5%, the mass ratio of sodium alginate to starch is 0.8:1, the above solution is heated to 40°C in a water bath and stirred at a speed of 200r / min, and mixed evenly to obtain a mixed solution, the above The mixed solution was cooled to room temperature. Add 20 g CaCl to 500 mL deionized water 2 , to obtain a mass volume concentration of 5% CaCl 2 Drop the above-mentioned cooled mixed solution into the cross-linking agent solution at a rate of 1 drop / s with a syringe, granulate into spherical particles with a particle size of 4-6 mm, and cross-link at 4°C for 24 hours Finally, after washing with pure water, the slow-release carbon...

Embodiment 2

[0030] In this example, the preparation method of the slow-release carbon source material based on sodium alginate is as follows: Weigh 24 g of sodium alginate and 20 g of starch and dissolve them in 400 mL of pure water to prepare a mixture containing 6% sodium alginate, A mixed solution of starch with a mass volume concentration of 5%, the mass ratio of sodium alginate and starch is 1.2:1, the above solution is heated to 35 °C in a water bath and stirred at a speed of 250 r / min, and mixed evenly to obtain a mixed solution, the above The mixed solution was cooled to room temperature. Add 8 g of CaCl to 500 mL of deionized water 2 , to obtain a mass volume concentration of 2% CaCl 2 Drop the above-mentioned cooled mixed solution into the cross-linking agent solution at a rate of 2 drops / s with a dropper, granulate into spherical particles with a particle size of 4-6mm, and cross-link at 3°C After 20 h, wash with pure water to obtain the slow-release carbon source material ba...

Embodiment 3

[0033]In this example, the preparation method of the slow-release carbon source material with sodium alginate as the base material is as follows: Weigh 32 g of sodium alginate and 20 g of starch and dissolve them in 400 mL of pure water to prepare a mixture containing 8% sodium alginate, A mixed solution of starch with a mass volume concentration of 5%, the mass ratio of sodium alginate to starch is 1.6:1, the above solution is heated to 45°C in a water bath and stirred at a speed of 300 r / min, and mixed evenly to obtain a mixed solution, the above The mixed solution was cooled to room temperature. Add 24 g CaCl to 500 mL deionized water 2 , to obtain a mass volume concentration of 6% CaCl 2 Drop the above-mentioned cooled mixed solution into the cross-linking agent solution at a rate of 3 drops / s with a dropper, granulate into spherical particles with a particle size of 4-6mm, and cross-link at 4°C After 30 h, wash with pure water to obtain the slow-release carbon source ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com