Slow controlled-release fertilizer used for corn

A slow and controlled release fertilizer and corn technology, applied in the fields of application, nitrogen fertilizer, potassium fertilizer, etc., can solve the problems of incomplete matching of nutrient absorption in the duration of fertilizer effect, lack of biomass in urea-formaldehyde fertilizer, and poor slow-release effect, etc., to improve nitrogen Sustained-release performance of the element, improvement of soil, and the effect of reducing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

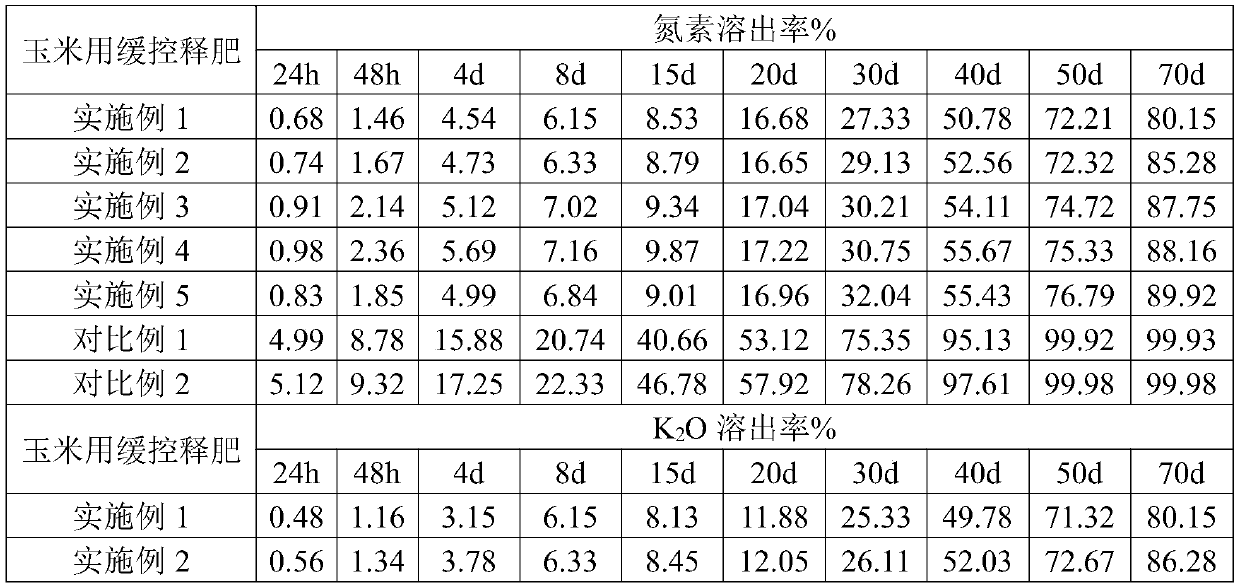

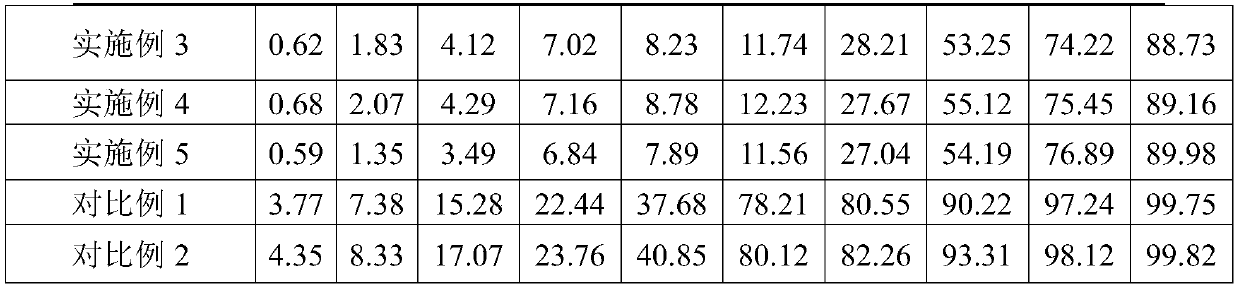

Examples

Embodiment 1

[0022] The slow and controlled release fertilizer for corn of the present embodiment is made of the following raw materials in parts by weight: 13 parts of urea furfural condensate, 35 parts of furfural slag, 14 parts of rice husk charcoal, 27 parts of compound fertilizer, 13 parts of vermiculite powder; The compound fertilizer is composed of urea, diammonium phosphate and potassium sulfate with a mass ratio of 8:8:20; the particle diameter of the vermiculite powder ≥ 74 μm; the particle diameter of the rice husk charcoal ≥ 165 μm; the furfural slag Particle size ≥ 165μm;

[0023] The preparation method of the urea furfural condensate is as follows: dissolve urea in water, adjust the pH value to 8.3 with 5% KOH solution and 3% boric acid by mass fraction, then add furfural, stir while adding, and finish adding After furfural, keep the temperature at 53°C for 1h, then raise the temperature to 70°C, stir and adjust the pH value to 5.3 with acetic acid and ammonium acetate buffer...

Embodiment 2

[0025] The slow-release fertilizer for corn of the present embodiment is made of the following raw materials in parts by weight: 8 parts of urea furfural condensate, 33 parts of furfural residue, 15 parts of rice husk charcoal, 30 parts of compound fertilizer, 14 parts of vermiculite powder; The particle size of the vermiculite powder is ≥74 μm; the particle size of the rice husk charcoal is ≥165 μm; the particle size of the furfural slag is ≥165 μm;

[0026] The preparation method of the urea furfural condensate is as follows: dissolving urea in water, adjusting the pH value to 8 with a mass fraction of 5% KOH solution and a mass fraction of 3% boric acid, then adding furfural, stirring while adding, and finishing the addition After furfural, keep the temperature at 50°C for 1h, then raise the temperature to 70°C, stir and adjust the pH value to 5 with acetic acid and ammonium acetate buffer system, and keep it at 70°C for 0.5h, then heat it at 75°C Grinding after drying unde...

Embodiment 3

[0028] The slow-release fertilizer for corn of the present embodiment is made of the following raw materials in parts by weight: 18 parts of urea furfural condensate, 37 parts of furfural residue, 13 parts of rice husk charcoal, 25 parts of compound fertilizer, 12 parts of vermiculite powder; The compound fertilizer is composed of urea, diammonium phosphate and potassium sulfate with a mass ratio of 8:8:20; the particle diameter of the vermiculite powder ≥ 74 μm; the particle diameter of the rice husk charcoal ≥ 165 μm; the furfural slag Particle size ≥ 165μm;

[0029] The preparation method of the urea furfural condensate is as follows: dissolve urea in water, adjust the pH value to 8.5 with 5% KOH solution and 3% boric acid by mass fraction, then add furfural, stir while adding, and finish adding After furfural, keep the temperature at 55°C for 1h, then raise the temperature to 70°C, stir and adjust the pH value to 5.5 with acetic acid and ammonium acetate buffer system, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com