Composite molding die for polyethylene winding structure wall tube

A structural wall pipe and composite molding technology, which is applied in the field of polyethylene winding structure wall pipe composite molding molds, can solve the problems affecting the release of the pipe and the service life of the mold core pipe, the easy deformation of the mold core pipe, and the inconvenience of replacing the mold core pipe. problems, to achieve the effect of small deformation, prolonging service life and eliminating lap joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

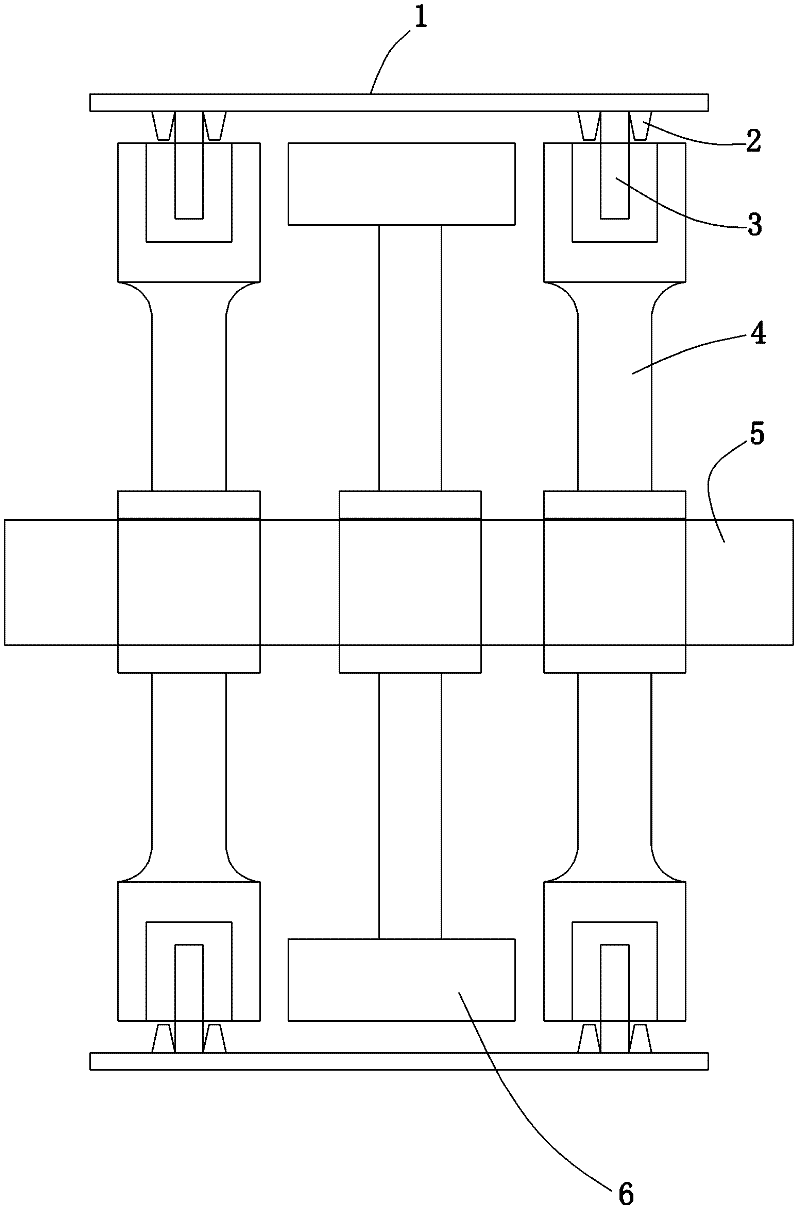

[0031] Embodiment 1: A kind of polyethylene winding structure wall pipe composite molding mold (see attached figure 1 ), including a cylinder 1 with a smooth outer wall, two sets of parallel support frames 4 are arranged inside the cylinder, the support frames are supported at both ends of the inner wall of the cylinder, and a hot air heating device 6 is arranged between the two support frames.

[0032] The cylinder has a smooth outer wall, and two annular ribs 2 are respectively fixed on both ends of the inner wall of the cylinder. The cross-section of the ribs is trapezoidal, and the two ribs at the same end form a guide rail. The outer diameter of the cylinder is adapted to the inner diameter of the polyethylene winding structure wall pipe to be produced, and the length of the cylinder is equal to 2.5 times the width of the winding unit of the polyethylene winding structure wall pipe to be produced.

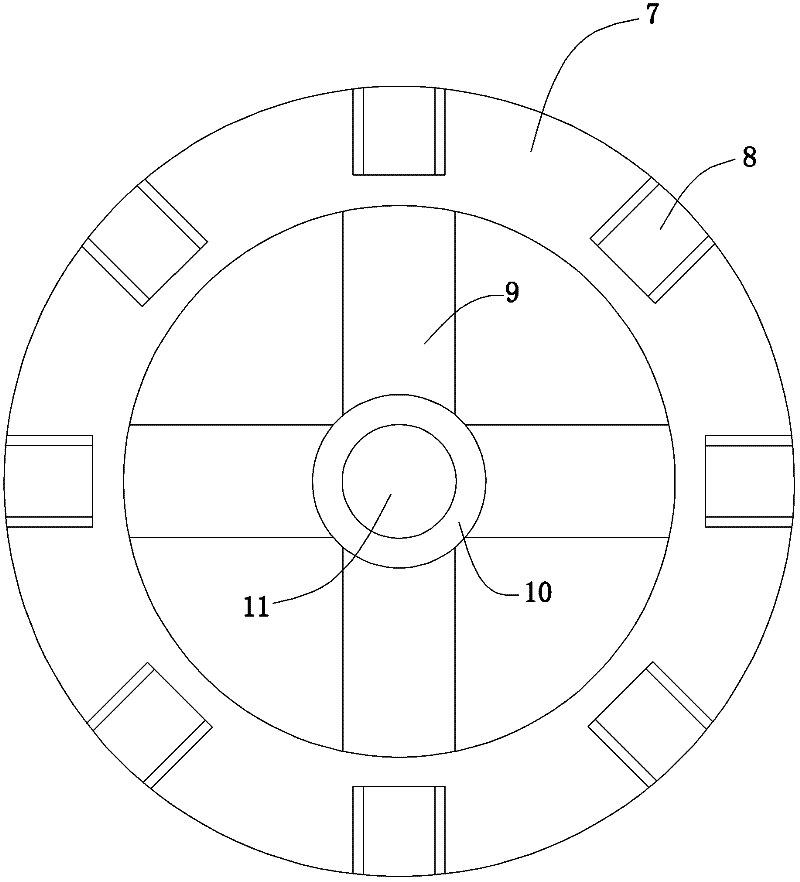

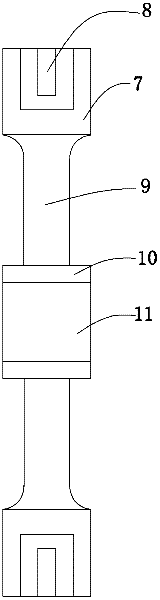

[0033] The periphery of the support frame is the support edge 7 (see atta...

Embodiment 2

[0036] Embodiment 2: A kind of polyethylene winding structure wall pipe compound molding mold (see attached Figure 8 ), an electric heating device is arranged inside the cylinder, and the electric heating device includes a plurality of electric heating plates 27 fixed at intervals on the inner wall of the cylinder. Each electric heating plate is arc-shaped, and the distance between the electric heating plates is even long. All electric heating plates are connected in parallel with each other. After parallel connection, the two poles are drawn out at both ends and the power transmission brush 28 is fixed. A closed annular brush holder 28 is fixed at the position corresponding to the power transmission brush on the two supporting frames in the cylinder. The ring-shaped brush holder on the frame is opposite, and the transmission brush is matched with the ring-shaped brush holder. Refer to Example 1 for all the other structures.

[0037] Taking the production of carat pipe as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com