P91 seamless steel pipe and method for manufacturing same

A technology for seamless steel pipes and steel pipes, which is applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of high metal consumption, long production process, unstable product quality, etc., so as to achieve short production process and improve metal yield. And the effect of steel pipe yield and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

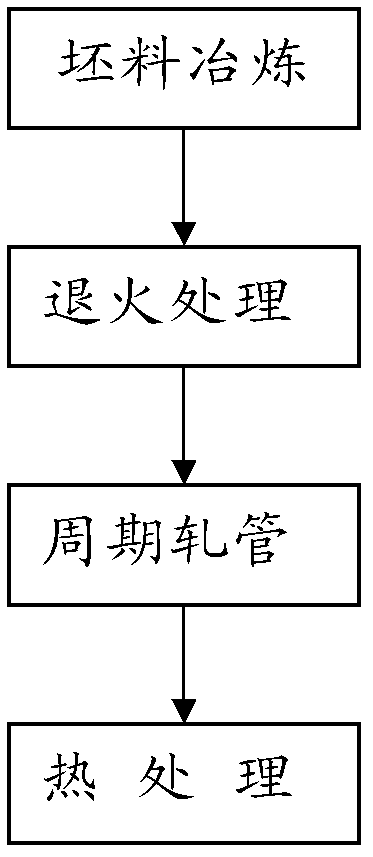

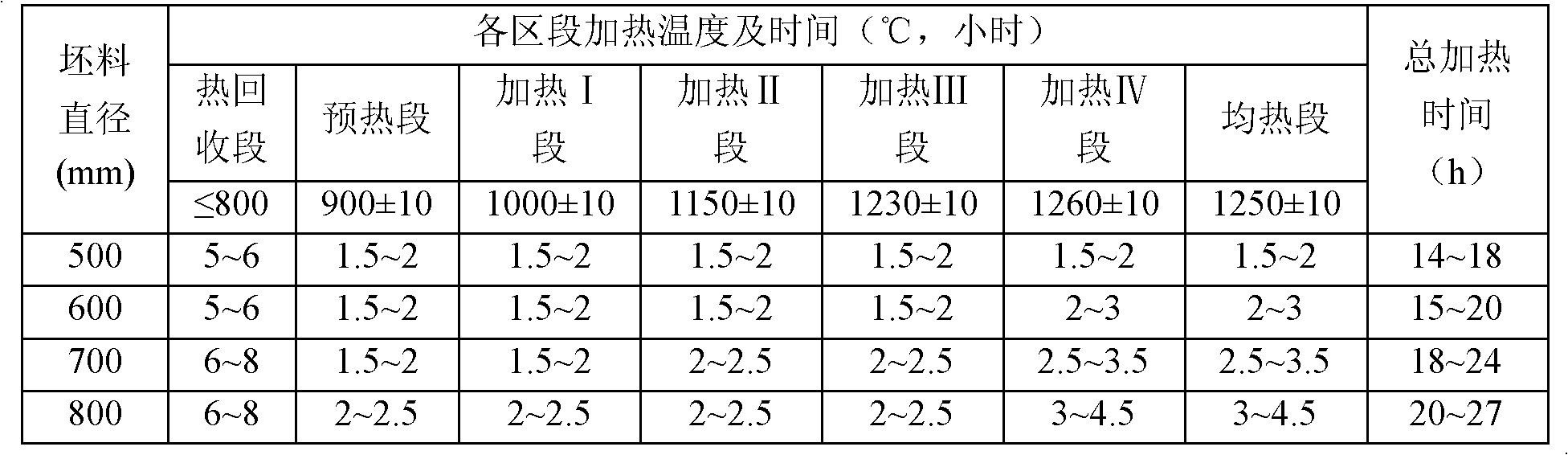

[0023] In a typical implementation of the present invention, a kind of preparation method of P91 seamless steel pipe is provided, such as figure 1 As shown, it includes the following steps: billet smelting, the raw material is smelted and refined through the vacuum degassing continuous casting round tube billet process to obtain the billet; annealing treatment, the billet is subjected to high-temperature diffusion annealing or low-temperature isothermal annealing; Soak the processed billet, the soaking temperature is 1230-1270°C, the soaking temperature deviation is ±10°C, and keep for 1.5-3 hours; hot-rolled and pierced the billet after soaking, the temperature of hot-rolled piercing is 1100-1200°C; Then carry out periodic rolling, the temperature of periodic rolling is 950-1100°C, carry out sizing and cooling treatment; and heat treatment, the steel pipe which has undergone periodic rolling is heated to 1040-1080°C, normalized, cooled after heat preservation, and then Heatin...

Embodiment 1

[0039] Adopt the preparation method of the present invention to produce the seamless steel pipe of Φ711*63mmP91.

[0040] 1) Optimization of chemical composition of P91 steel

[0041] According to the ASME SA335 standard, the chemical composition of P91 steel is optimized. The chemical composition of the optimized P91 steel is as follows (mass fraction, %): C 0.08~0.12%, Si 0.20~0.45%, Mn 0.35~0.55%, P≤ 0.015%, S≤0.007%, Cu≤0.15%, Ni≤0.20%, Cr 8.10~9.30%, Mo 0.85~1.05%, V 0.18~0.23%, Nb 0.06~0.10%, N0.030~0.070%, Al ≤0.020%, Ti≤0.010%, Zr≤0.010%, the balance is Fe and unavoidable impurities;

[0042] 2) Smelting of blanks

[0043] Using high-quality molten iron and scrap steel as raw materials, the billet is smelted through 45-ton electric furnace smelting, 45-ton refining furnace refining, 45-ton vacuum degassing furnace and round billet arc continuous casting machine continuous casting process. During the smelting process, the quality of P91 steel is strictly controlled. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com