Method for preparing mustard sauce with full-bodied flavor without additional mustard oil

A mustard sauce and mustard oil technology, applied in food preparation, application, food science and other directions, can solve the problems of insufficient mellowness, reduced volatility of allyl isothiocyanate, differences in myrosinase activity, etc., and achieves mild color and luster. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

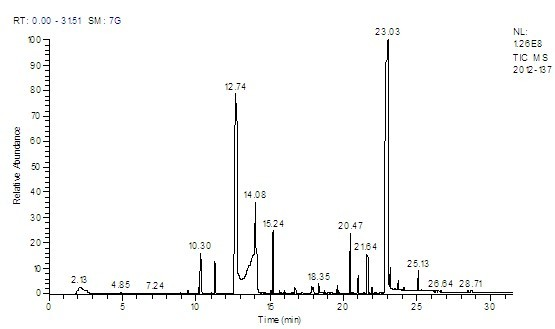

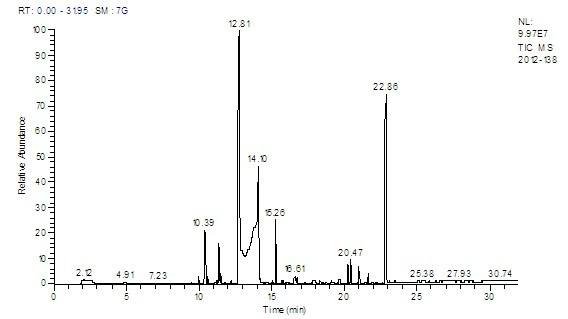

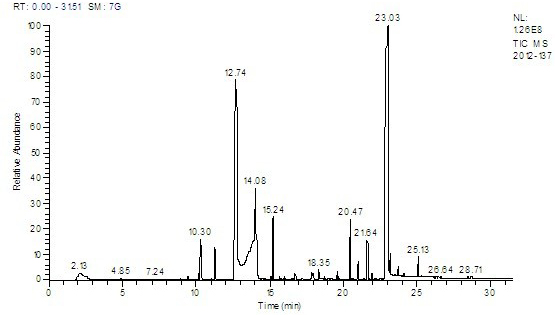

Image

Examples

Embodiment 1

[0042] Example 1 Sweet mustard sauce

[0043] Raw material pretreatment: cut fresh horseradish into thin slices, dry to constant weight in a vacuum constant temperature blast drying oven at 45-50°C, then coarsely crush the dried horseradish slices, pass through a 100-mesh sieve after coarse crushing spare. The horseradish powder is ultrafinely pulverized by the airflow ultrafine pulverization method. The process parameters are: working pressure 0.6MPa, sorting frequency 20Hz, and pulverization once. The average particle size of the ultrafinely pulverized horseradish powder can reach 14 μm.

[0044] Weigh raw materials and additives according to the following proportions: 20% horseradish powder, 2% lactose, 0.4% sodium carboxymethyl cellulose, 0.6% sodium alginate, 0.5% soybean protein, 0.1% edible salt, 0.08% white pepper, MSG 0.4%, edible oil 7.5%, ginger powder 0.5%, orange juice 3%, citric acid 0.1%-0.2%, ascorbic acid 0.08%, water to make up 100%.

[0045] Preparation fo...

Embodiment 2

[0046] Example 2 salty mustard sauce

[0047] Raw material pretreatment: Cut fresh horseradish into thin slices, dry in an electric heating constant temperature blast drying oven at 40-50°C until constant weight, then coarsely grind the dried horseradish slices, pass through a 100-mesh sieve after coarse grinding spare. The horseradish powder is ultrafinely pulverized by the airflow ultrafine pulverization method. The process parameters are: working fluid pressure 0.7MPa, sorting frequency 25Hz, and pulverization twice. The average particle size of the horseradish powder after ultrafine pulverization can reach 12.5 μm.

[0048] Raw materials and additives were weighed according to the following proportions: 19% horseradish powder, 0.5% lactose, 0.5% sodium carboxymethyl cellulose, 0.6% sodium alginate, 0.5% soybean protein, 0.4% edible salt, 0.1% white pepper, Monosodium glutamate 0.5%, edible oil 7.5%, ginger powder 0.5%, lemon juice 4%, citric acid 0.2%, ascorbic acid 0.08...

Embodiment 3

[0050] Example 3 Fruity Mustard Sauce

[0051] Raw material pretreatment: cut fresh horseradish into thin slices, dry in an electric heating constant temperature blast drying oven at 45-50°C to constant weight, then coarsely grind the dried horseradish slices, pass through a 100-mesh sieve after coarse grinding spare. The airflow ultrafine pulverization method is used to ultrafinely pulverize the horseradish powder. The process parameters are: working fluid pressure 0.8MPa, sorting frequency 20Hz, pulverization once, and the average particle size of the horseradish powder after ultrafine pulverization can reach 25.3 μm.

[0052] Raw materials and additives were weighed according to the following proportions: 19% horseradish powder, 1% lactose, 0.5% sodium carboxymethyl cellulose, 0.6% sodium alginate, 0.5% soybean protein, 0.2% edible salt, 0.1% white pepper, 0.5% monosodium glutamate, 7.5% edible oil, 0.6% ginger powder, 8% apple juice, 0.2% citric acid, 0.08% ascorbic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com