Method and device for spraying thermal fog carried biological pesticide

A biopesticide and thermal smoke technology, applied in botany equipment and methods, plant protection, horticulture, etc., can solve the problems of pesticide decomposition, denaturation, and loss of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

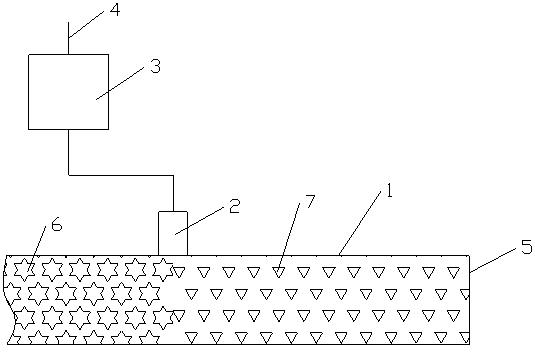

Image

Examples

Embodiment 1

[0023] Embodiment 1: Bacillus thuringiensis (Bt) thermal atomization activity test

[0024] 1. Thermal mist preparation

[0025] Glycerin (glycerin) and water were selected as the solvents for Bacillus thuringiensis hot spray, and were prepared according to three volume ratios of 55:45, 65:35, and 75:25. bacteria in a 500mL Erlenmeyer flask. Add 10% by volume (referring to adding 50mL Bacillus thuringiensis fermentation broth) to each 500mL preparation respectively to prepare the Bacillus thuringiensis hot spray. Then add anti-oxidant sodium benzoate with a volume ratio of 3‰, Tween-20 with 3‰, and inhibitor sodium dodecylbenzoate with 3‰ respectively, shake well, and prepare three kinds of hot fog agents A1, A2 and A3 Preparations are stored at room temperature for later use.

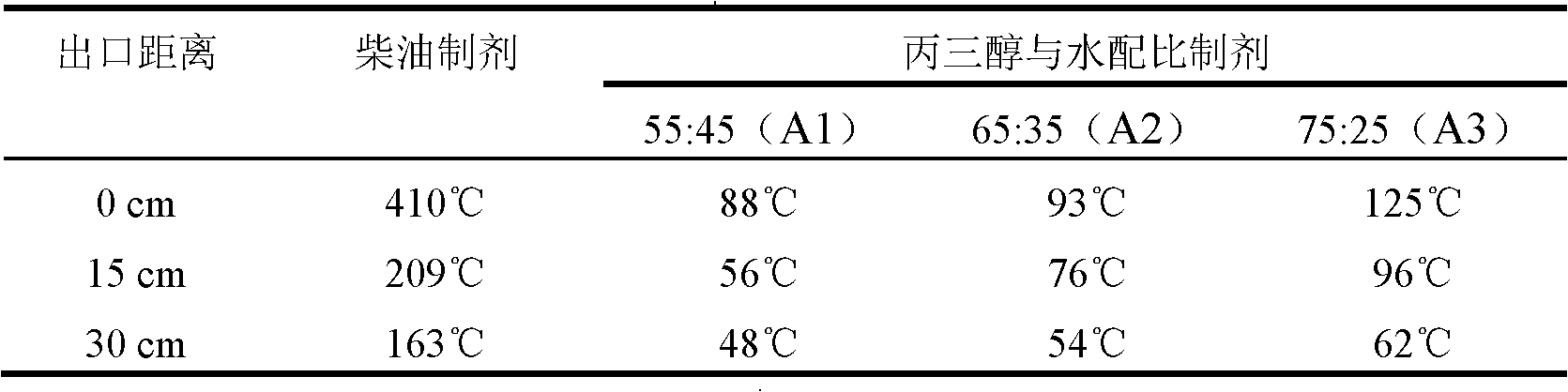

[0026] 2. Smoke temperature at nozzle outlet

[0027] Using diesel oil as a control, put the prepared A1, A2, A3 Bacillus thuringiensis thermal sprays into the medicine box of the 6HY-25 fog machin...

Embodiment 2

[0040] Embodiment 2: Beauveria bassiana thermal atomization activity test

[0041] 1. Beauveria bassiana thermal spray preparation

[0042] Choose glycerol and water as the solvent of Beauveria bassiana thermal mist, according to three volume ratios of glycerin and water 55: 45, 65: 35, 75: 25, Beauveria bassiana high spore powder: solvent (1: 50 ) is prepared into 2% Beauveria bassiana thermal mist by volume, each with 250mL preparations, which are respectively denoted as A1, A2, and A3, and are respectively packed in sterilized 500mL triangular flasks, and 3‰ of antioxidant benzene is added respectively. Sodium formate, 3‰ Tween-80, 3‰ inhibitor sodium dodecyl benzoate, shake well, store in 4℃ environment for later use.

[0043] 2. Measurement of the temperature of the smoke and droplets at the outlet of the nozzle

[0044] Using No. 0 diesel oil as a comparative test, put the prepared A1, A2, and A3 Beauveria bassiana hot fog agents into the medicine box of the 6HY-25 fog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com