Negative plate for lead acid battery

A technology for battery packs and pole plates, which is applied to the electrodes of lead-acid batteries, lead-acid batteries, and battery electrodes, etc. It can solve problems such as shortened life of battery packs, corrosion of positive grid alloys, loss of excess water, etc., to reduce maintenance, The effect of reducing the amount of overcharge and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] Example 1: Capacitor Slurry and Capacitor Negative Plate Formation

[0039] First, a carbon negative active material slurry was prepared by mixing 10 lbs of lead oxide powder, 3.8 g of polyester fiber, and 0.135 lbs of expander and carbon additives in a mixer. The lead oxide powder used in this example contained some pure lead. The weight of pure lead plus the weight of lead in lead oxide is 94.69wt% of the lead oxide powder. The expansion agent in each slurry contains 0.1 lbs of BaSO 4 , 0.02 lbs of lignosulfonate sodium salt (Lignin Vanisperse A) and 0.015 lbs of carbon black. Carbon additives for various examples include carbon black, graphite, activated carbon, and combinations of these materials. The specific amounts and types of carbon additives used for each plate are described in specific examples. The amount of carbon addition varied from about 1% to about 12% by mass of lead oxide throughout the test period. If the amount of carbon additive is greater tha...

example 2

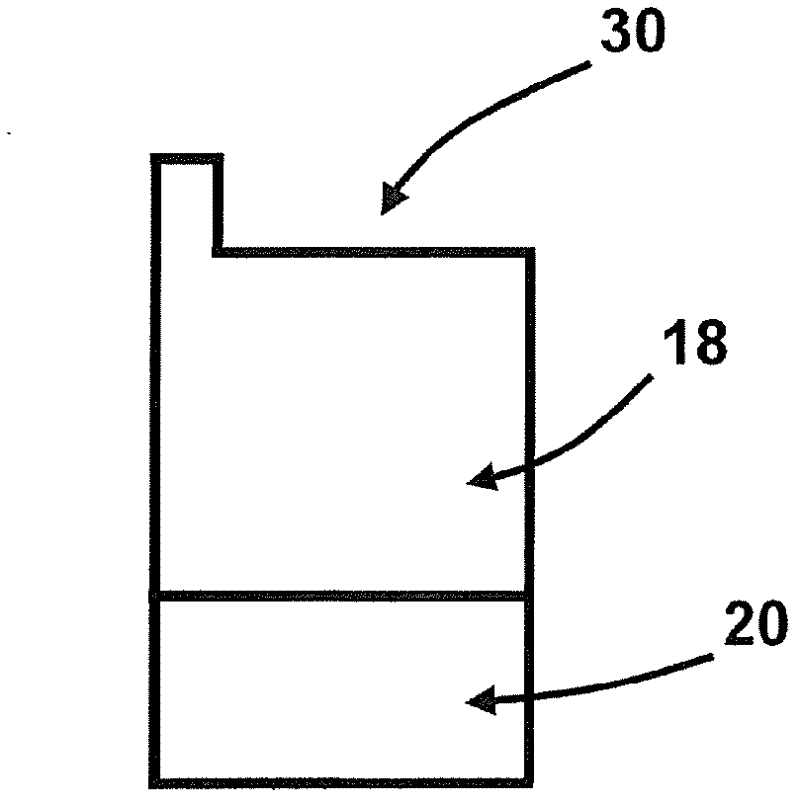

[0043] Example 2: Hybrid Negative Plate Formation

[0044] The conventional negative paste described in Comparative Example 1 was used for the top portion of the negative electrode grid, and the capacitor paste described in Example 1 was used for the bottom portion of the negative electrode grid. The surface area of the negative electrode grid covered by the carbon negative slurry varied between approximately 14% and 48% of the negative electrode grid. The resulting hybrid negative plate was then processed as described in Example 1 to form a hybrid negative plate.

example 1-2 and comparative example 1

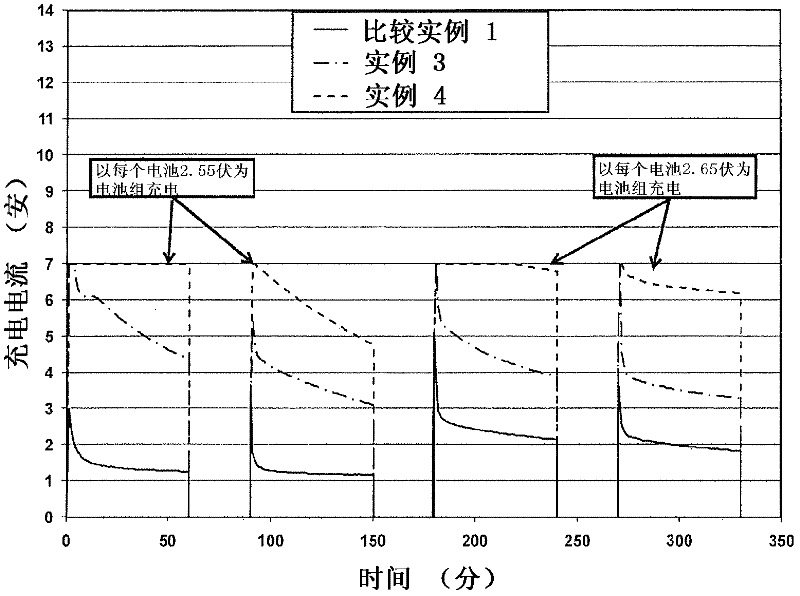

[0045] Examples 1-2 and Comparative Example 1: Battery Assembly

[0046] Each set is assembled into a single 2 volt battery case. Each battery contains 6 positive plates and 6 negative plates. The plates alternate with conventional separators in between. The positive plate contains a grid of positive electrode plates. Each positive electrode grid was slurried with a positive slurry comprising lead oxide, polyester fiber, water, and sulfuric acid. This plate was then treated in the same manner as the negative plate.

[0047] The tabs of the negative plate of each cell are welded together using known processes. Similarly, the tabs of the positive plates of each cell are welded together using known processes. Then, the assembled battery was filled with an aqueous sulfuric acid solution. Within thirty minutes of filling the cell with acid, the plate formation step began. According to the plate forming steps, a charge is applied to the battery using a constant current formin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com