High-voltage power supply of electron beam melting furnace

A technology of electron beam melting furnace and high voltage power supply, applied in the direction of improving energy efficiency, circuits, electrical components, etc., can solve the problems of high voltage operation process fluctuation, large DC high voltage output ripple, increase transformer capacity, etc., to achieve high power factor and Efficiency, no delay in response speed, effect of reducing harmonic currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

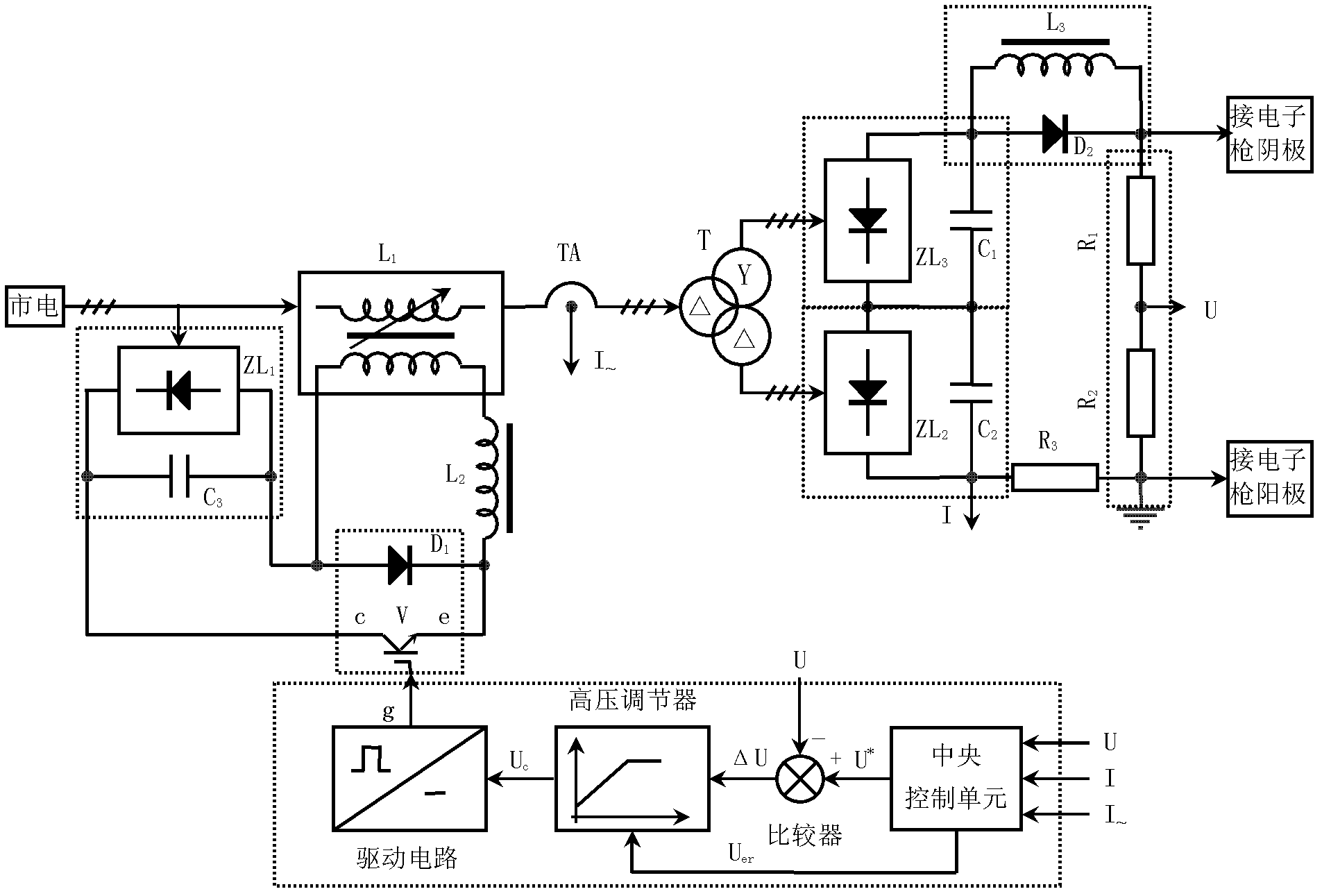

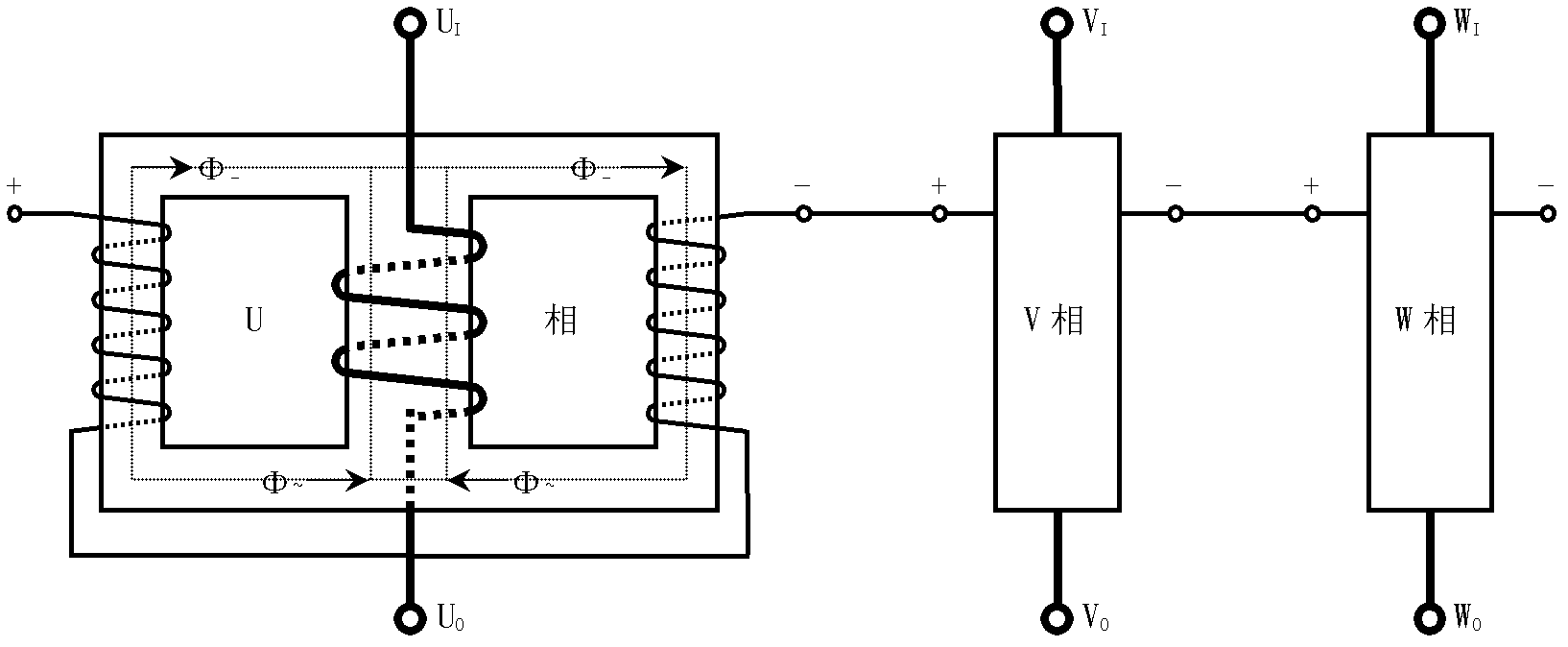

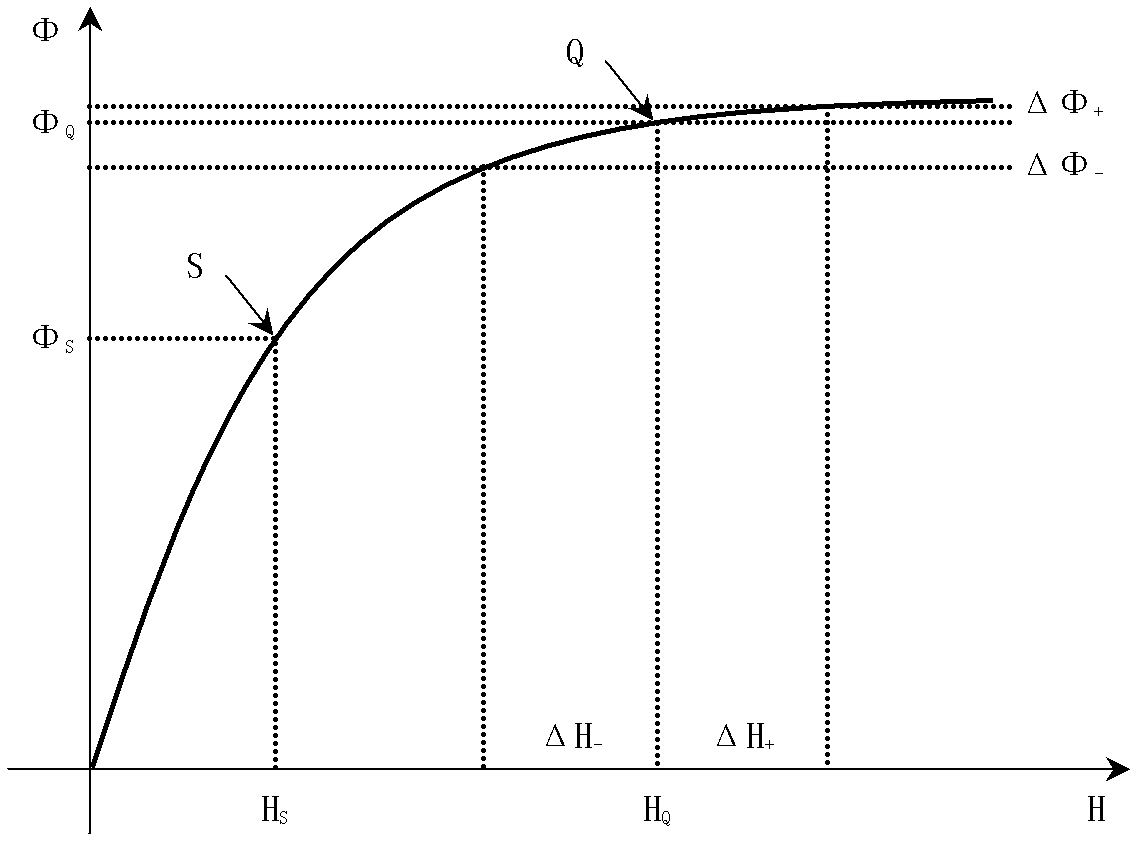

[0027] The invention relates to a control method for a high-voltage power supply of an electron beam melting furnace. The high-voltage power supply adopts an output voltage closed-loop control structure, is powered by a three-phase commercial power supply, and adjusts the input primary side voltage of a high-voltage transformer by adjusting the working state of a controllable reactor. The power supply is output in a current conversion mode of power frequency AC input → three-phase adjustable reactor L1 voltage regulation → three-phase step-up transformer T step-up → high-voltage rectification and filtering; the above-mentioned high-voltage output high-voltage sampling signal is used as a negative feedback signal, The current of the DC control winding of the three-phase adjustable reactor L1 is controlled by the voltage regulator, and the voltage is automatically adjusted to keep the output voltage value of the high-voltage power supply of the electron beam melting furnace stable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com