Combination type variable speed direct current permanent magnet motor

A permanent magnet motor and combined technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of large torque, large motor volume, and different requirements for motor output speed, and achieve large speed ratio and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

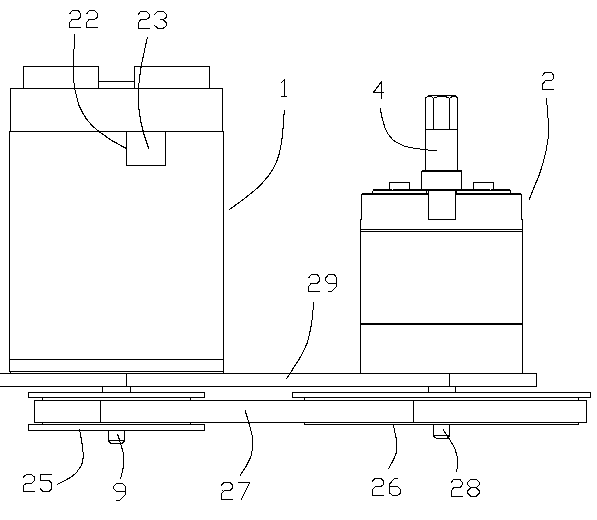

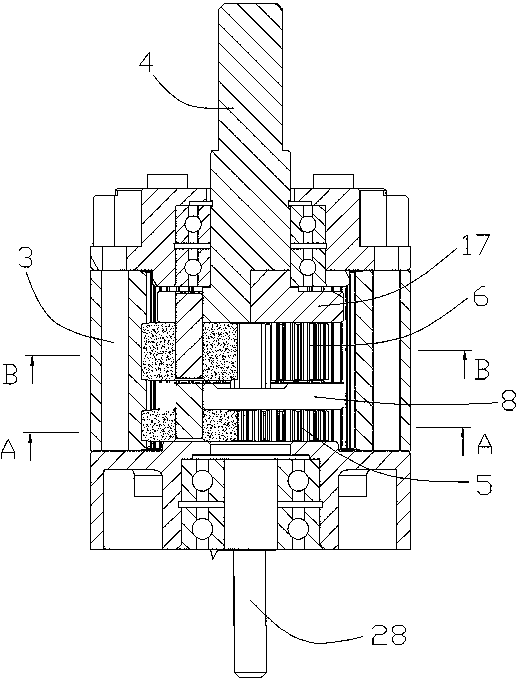

[0025] In this embodiment, a combined variable speed DC permanent magnet motor, such as figure 1 Shown, comprise motor 1 and reduction box 2, motor and acceleration box are all installed on the fixed plate 29, and the motor output shaft 9 of motor passes fixed plate, and driving wheel 25 is installed on the motor output shaft front end; Case input shaft 28 also passes fixed plate, and driven wheel 26 is installed on reduction box input shaft front end, is with synchronous belt 27 on driving wheel and driven wheel, links to each other by synchronous belt transmission.

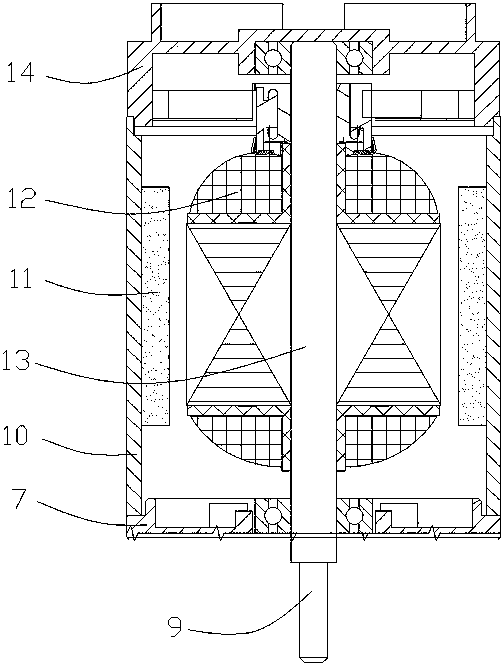

[0026] The motor is a DC permanent magnet motor, such as image 3 As shown, the motor includes a housing, and the housing is composed of a front end cover 7, a motor barrel 10 and a rear end cover 14, and a rotating shaft 13 is arranged in the housing, one end of the rotating shaft is arranged on the rear end cover through a bearing, and the other end of the rotating shaft passes through the front end Cover and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com