Method for detecting content of monascus pigments in meat products

A technology of monascus pigment and meat products, applied in the field of qualitative or quantitative detection of red yeast pigment content in meat products, detection of red yeast pigment content in meat products, can solve the problem of no qualitative and quantitative analysis of components of monascus pigment Monascus pigment quantitative and qualitative methods, unable to detect the concentration and other problems, to achieve the effect of simple and clear pre-treatment steps, good extraction effect, and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

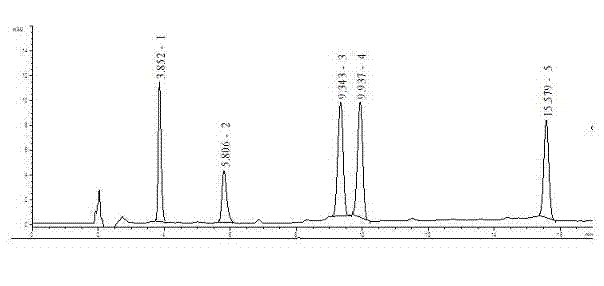

[0082] Weigh six prepared sausage samples, 2.00g each, place them in a 50mL centrifuge tube, add a certain amount of standard solution respectively, and prepare samples with three concentrations of 0.5 mg / kg, 1.0 mg / kg and 5.0 mg / kg solution, each concentration was done in parallel, each sample was added with 15 mL of methanol + ethyl acetate (2+8 V / V) solution, 3 g of anhydrous sodium sulfate, 20 mg of ascorbic acid, vortexed for 30 s, ultrasonicated for 10 s min, centrifuge at 10000 r / min for 5 min. Transfer the supernatant to another 50 mL centrifuge tube. Add 10 mL of methanol+ethyl acetate (2+8 V / V) solution to the residue, and repeat the extraction once. The supernatants were combined, blown to near dryness with nitrogen at 40°C, and adjusted to 10.0 mL with ethyl acetate + cyclohexane (1+1 V / V), pending purification.

[0083] The liquid to be purified is injected into the gel permeation chromatography (GPC) column from a 5mL sample loop, set the pump flow rate to 5mL / ...

Embodiment 2

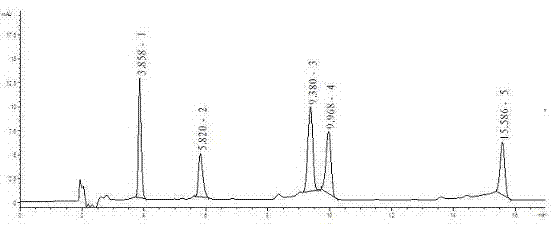

[0092] Weigh 2.00g each of six prepared roast chicken samples, put them in a 50 mL centrifuge tube, add a certain amount of standard solution respectively, and prepare three concentrations of 0.5 mg / kg, 1.0 mg / kg and 5.0 mg / kg For the sample solution, two parallels were made for each concentration, and the parameter settings of the sample pretreatment, data acquisition and processing system were the same as those in Example 1.

[0093] Concentrations of red yeast pigment standard series were 0.20 mg / mL, 0.50 mg / mL, 2.00 mg / mL, 5.00 mg / mL, and 10.0 mg / mL, respectively. Data using multipoint calibration.

[0094] According to the above multi-point correction method formula:

[0095]

[0096] The calculated average recoveries of three concentrations of 0.5 mg / kg, 1.0 mg / kg and 5.0 mg / kg in roast chicken were 76.3%, 87.0% and 90.7%, respectively. That is: if 1 kg of roasted chicken sample contains 0.5 mg, 1.0 mg or 5.0 mg of the components of monascus pigment, this detection ...

Embodiment 3

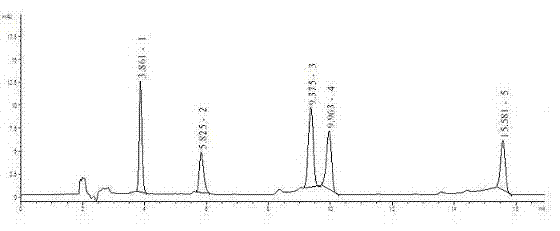

[0098] Weigh 2.00g each of six prepared ham samples, place them in a 50 mL centrifuge tube, add a certain amount of standard solution respectively, and prepare three concentrations of 0.5 mg / kg, 1.0 mg / kg and 5.0 mg / kg. Sample solution, two parallels were done for each concentration, and the parameter settings of the sample pretreatment, data acquisition and processing system were the same as those in Example 1.

[0099] Concentrations of red yeast pigment standard series were 0.20 mg / mL, 0.50 mg / mL, 2.00 mg / mL, 5.00 mg / mL, and 10.0 mg / mL, respectively. Data using multipoint calibration.

[0100] According to the above multi-point correction method formula:

[0101]

[0102] The calculated average recoveries of 0.5 mg / kg, 1.0 mg / kg and 5.0 mg / kg in ham were 77.6%, 88.7% and 93.4% respectively. That is: if 1 kg of ham sample contains 0.5 mg, 1.0 mg or 5.0 mg of the components of monascus pigment, this detection method can detect 0.388 mg, 0.887 mg and 4.67 mg corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com