Ultrasonic flaw-detecting machine for steel pipes

An ultrasonic and flaw detector technology, which is applied in the analysis of solids by sound waves/ultrasonic waves/infrasonic waves, material analysis by sound waves/ultrasonic waves/infrasonic waves, and measuring devices. and other problems, to achieve the effect of saving energy consumption, reducing air bubbles, and large water supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

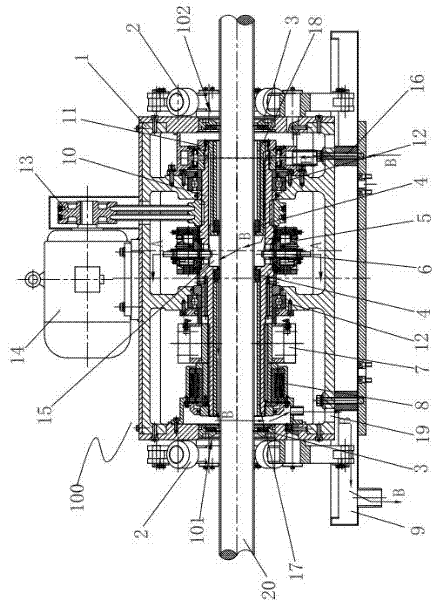

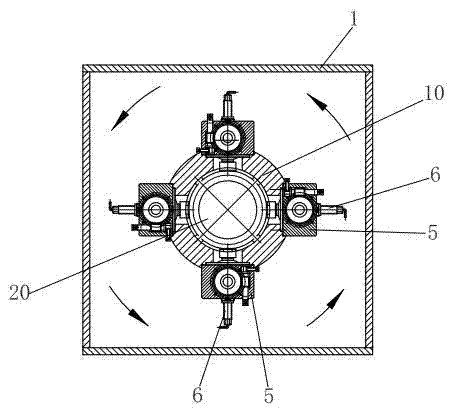

[0026] Such as Figure 1~3 As shown, the present invention includes a flaw detection host 100, a water storage tank and a control system (not shown in the figure), the flaw detection host 100 includes a box body 1, a water tray 9 is provided under the box body 1, and two ends of the box body 1 are provided with There is an inlet 101 and an outlet 102 of the steel pipe to be tested, and a water seal 3 is respectively arranged at the inlet 101 and the outlet 102, and the water seal 3 can prevent water from leaking outwards. The hollow main shaft 10 is rotatably installed in the box body 1 through the bearing 12, and the steel pipe 20 to be tested passes through the hollow main shaft 10, the inlet 101 and the outlet 102 during detection. An adjustable three-wheel centering device 2 is provided at the inlet 101 and the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com