Surface treatment method by directly sticking transfer film to ultrafine fiber napped leather

A superfine fiber and surface treatment technology, which is applied in the decoration of textiles, textiles and papermaking, etc., can solve the problems of chemical treatment agents with strong odor, large pollution of coating materials, and large environmental pollution, so as to save equipment investment and heat energy consumption , no solvent consumption and recovery, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

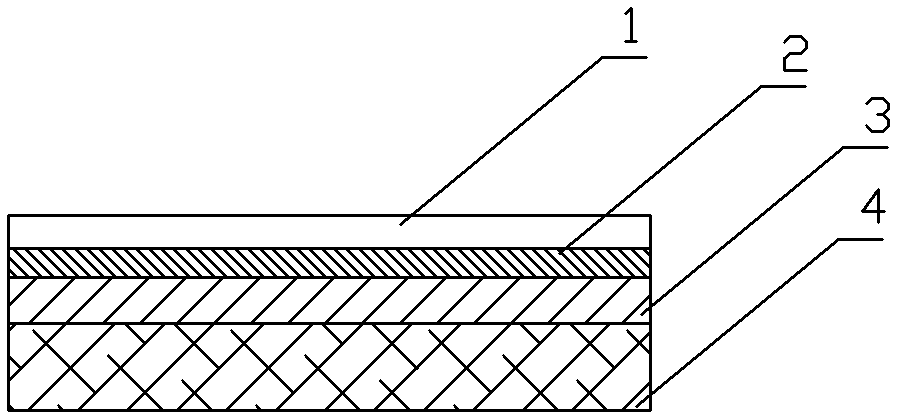

[0025] Example 1: as figure 1 As shown, the surface treatment method of the transfer film directly attached to the microfiber suede leather includes the following process steps:

[0026] 1) Prepare the material transfer film roll, and at the same time prepare the microfiber suede roll and the hot-pressing laminating machine;

[0027] The transfer film in the transfer film roll material includes a carrier layer 1 , a release layer 2 , and an adhesive layer 3 , the release layer is coated on the carrier layer 1 , and the adhesive layer is coated on the release layer. The carrier layer is a PET film layer. The adhesive layer is a TPU resin layer.

[0028] 2) Pulling the transfer film and the microfiber suede into alignment on the opposite rollers of the hot-pressing laminating machine, heating and rolling, wherein the carrier layer of the transfer film contacts the hot roller, and the adhesive layer of the transfer film contacts the microfiber suede leather 4;

[0029] 3) Con...

Embodiment 2

[0033] Example 2: as figure 2 As shown, the surface treatment method of the transfer film directly attached to the microfiber suede leather includes the following process steps:

[0034] 1) Prepare the material transfer film roll, and at the same time prepare the microfiber suede roll and the hot-pressing laminating machine;

[0035] The transfer film in the transfer film roll material includes a carrier layer 1, a release layer 2, an intermediate layer 5, and an adhesive layer 3. The release layer is coated on the carrier layer, the intermediate layer is coated on the release layer, and the adhesive layer is coated on the release layer. The layer is coated on the intermediate layer. The carrier layer is a PET film layer. The adhesive layer is a TPU resin layer. The intermediate layer is a color layer, which can be of various colors. The intermediate layer can also be a pattern layer.

[0036] 2) Pulling the transfer film and the microfiber suede into alignment on the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com