Treatment method for harmless reclamation of solid waste of heavy metal

A treatment method and recycling technology, applied in the field of harmless recycling of heavy metal solid waste, can solve the problems of scattered solid waste utilization business operations, high equipment maintenance costs, short service life, etc., and achieve recycling and comprehensive utilization , Reduce maintenance costs, reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

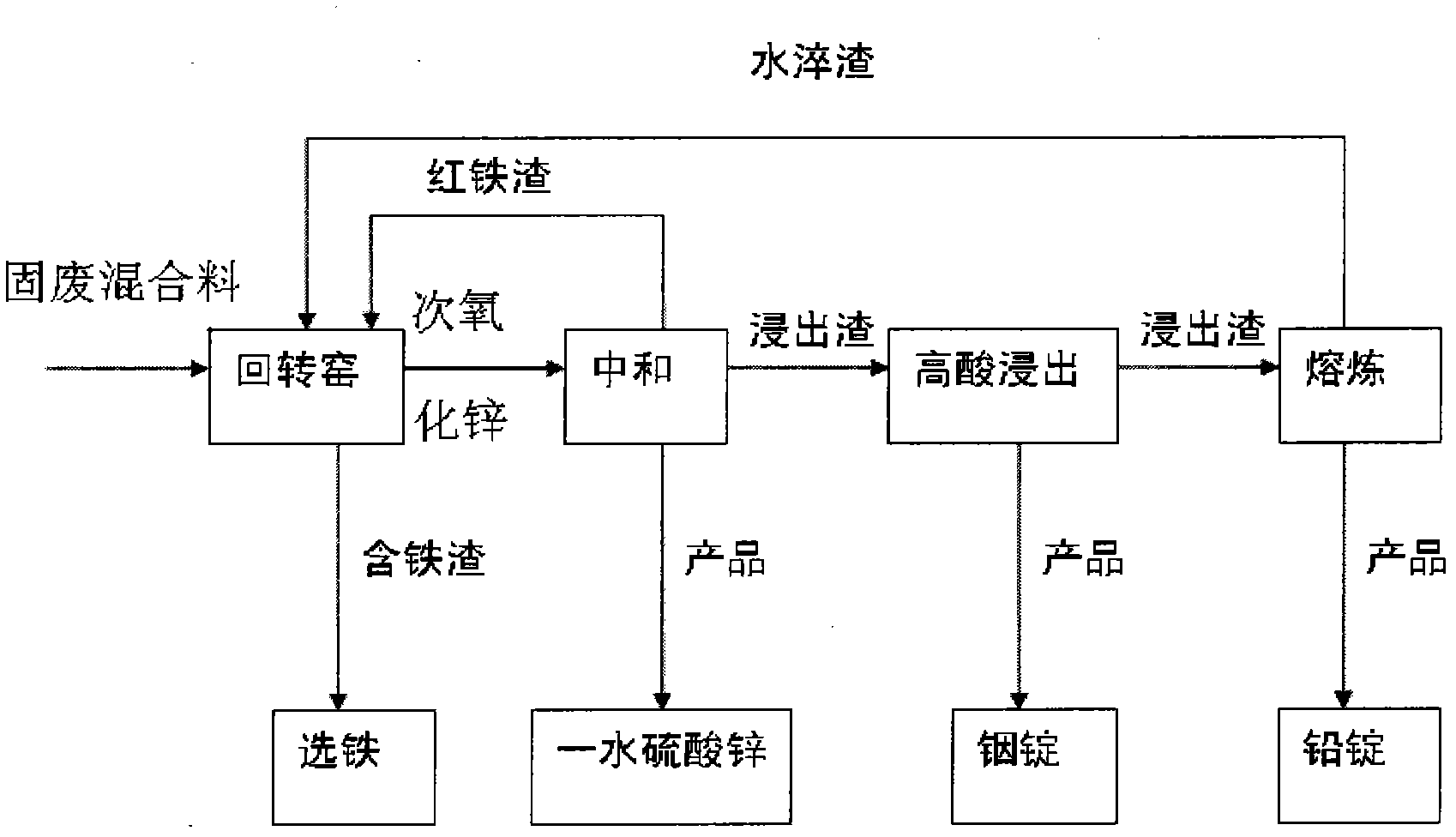

[0051] The invention provides a treatment method for the harmless recycling of heavy metal solid waste. The invention provides a treatment method for the harmless recycling of heavy metal solid waste. The rotary kiln is used for the harmless and resourceful treatment of heavy metal solid waste.

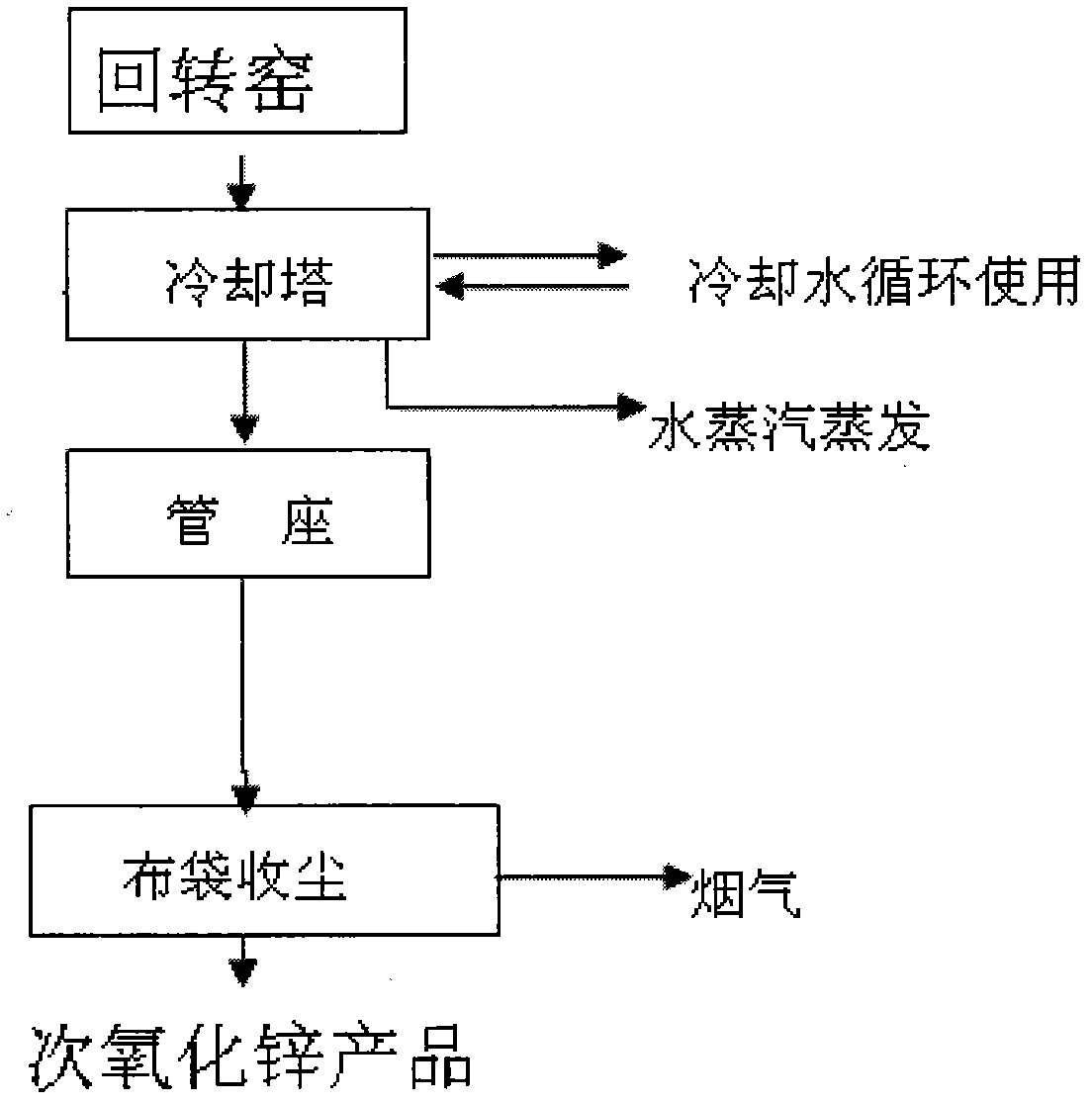

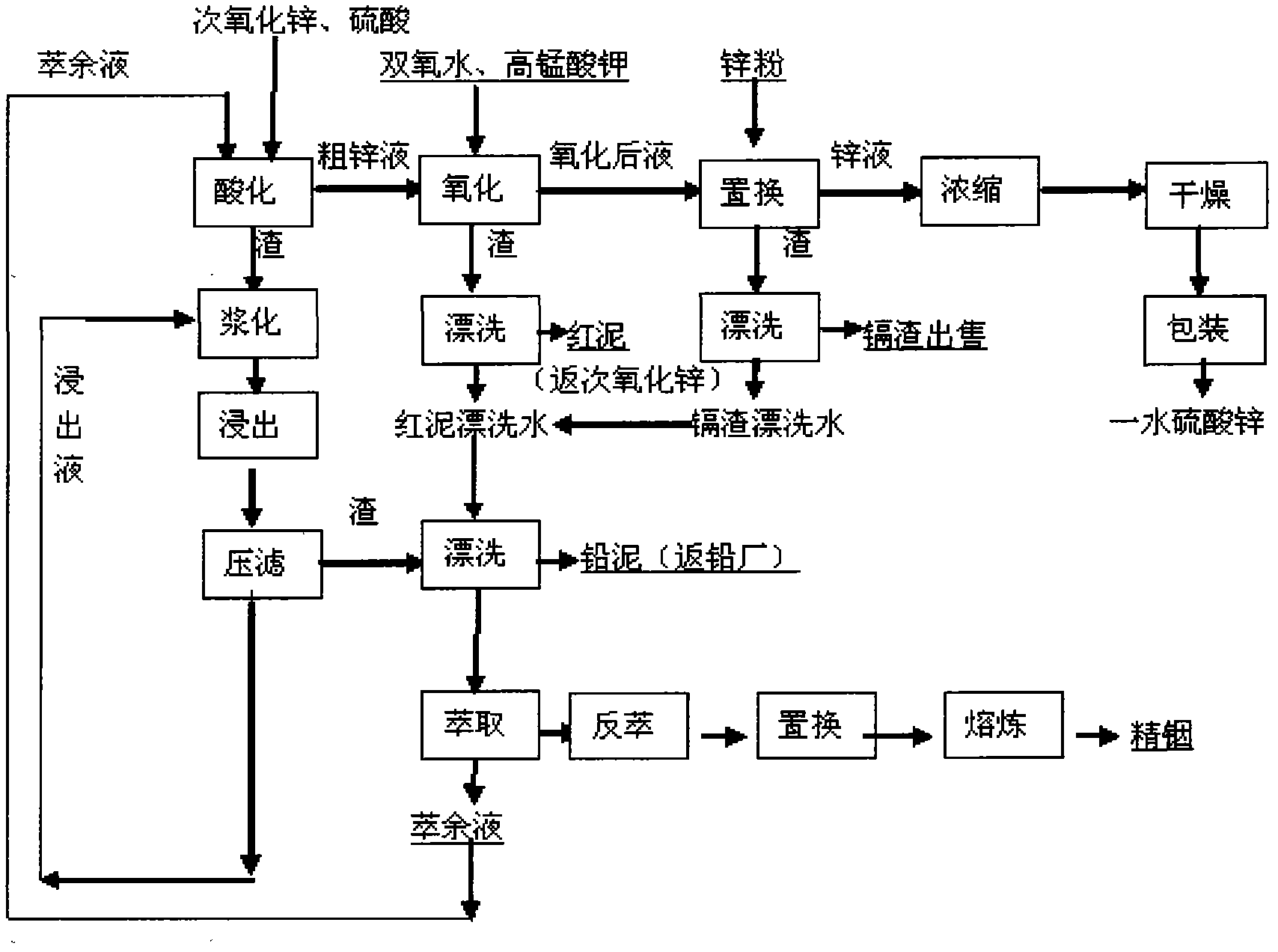

[0052] like figure 1 As shown, the specific treatment method is: coal-free low calorific value solid waste mixture is burned at high temperature in a rotary kiln to produce secondary zinc oxide, the temperature in the high temperature zone of the rotary kiln reaches 1300 ° C, and other valuable metals are enriched at the same time; the iron-containing waste slag produced by the rotary kiln As raw material for iron selection to produce iron powder; use secondary zinc oxide as raw material, produce zinc sulfate monohydrate through acid leaching and neutralization, produce red iron slag of zinc sulfate monohydrate as raw material of secondary zinc oxide, and produce leaching residue of z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com