High temperature corrosion inhibitor for oil refining device

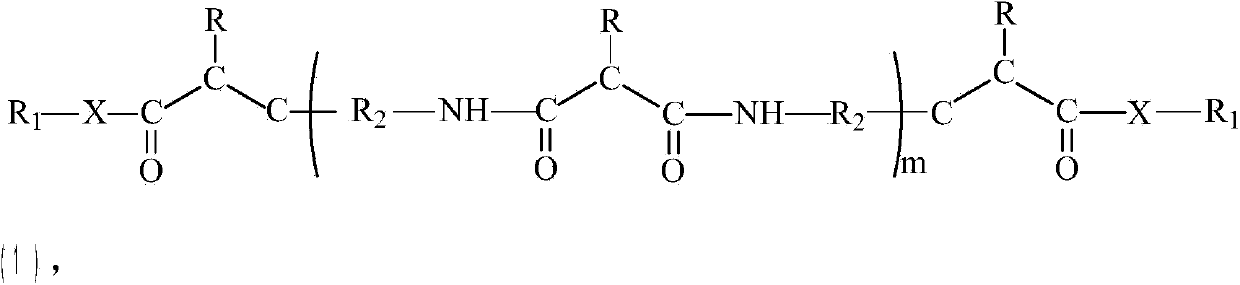

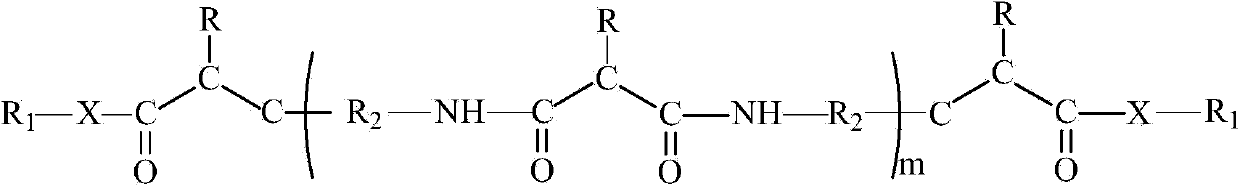

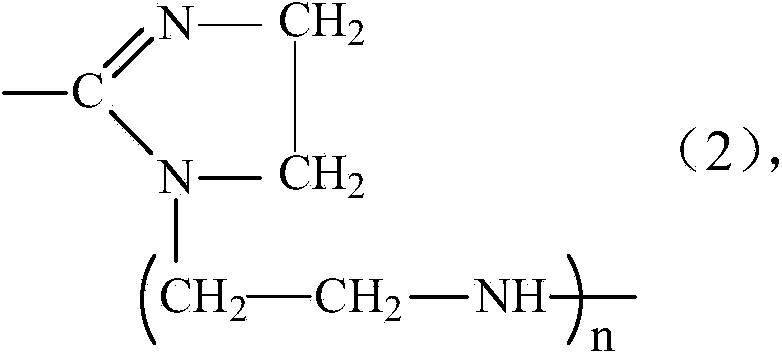

A high-temperature corrosion inhibitor and oil refining device technology, which is applied in the petroleum industry, hydrocarbon oil treatment, equipment corrosion/inhibition of dirt, etc. It can solve the problems of low operating temperature and easy detachment of the adsorption film, and achieve stable performance and dense adsorption film. , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of nitrogen-containing sulfur-containing polymer—put 85 grams of hexadecyl succinic anhydride and 100 grams of xylene into a 500-ml four-necked flask equipped with a stirrer, thermometer, water separator and condenser. Turn on the condensed water while disassembling the stirring device, then slowly add 30 g of hydroxybenzothiazole, heat up until the xylene starts to reflux, and react for 1 hour. Then 60 g of triethylenetetramine was added dropwise, and after reacting for 1 hour, the temperature was raised to 220° C., dehydrated, solvent removed, and cooled to 100° C. after constant temperature for 5 hours. Then add 200 grams of xylene and 35 grams of hexadecyl succinic anhydride, heat up until the xylene begins to reflux, react for 2 hours, and cool to obtain a xylene solution of nitrogen-containing and sulfur-containing polymers.

[0031] Preparation of high-temperature corrosion inhibitor—add 70 grams of the nitrogen-containing and sulfur-containing polymer ...

Embodiment 2

[0033] Preparation of nitrogen-containing sulfur-containing polymer——Put 98 grams of tetradecyl succinic anhydride and 100 grams of xylene into a 500-ml four-necked flask equipped with a stirrer, thermometer, water separator and condenser. Turn on the condensed water while using the stirring device, then slowly add 18 grams of hydroxybenzothiazole, heat up until the xylene starts to reflux, and react for 2 hours. Then, 72 g of tetraethylenepentamine was added dropwise, and after reacting for 1 hour, the temperature was raised to 220° C., dehydration and solvent removal were performed, and the temperature was kept constant for 5 hours, and then cooled to 100° C. Then add 200 grams of xylene and 22 grams of tetradecyl succinic anhydride, heat up to xylene and start to reflux, react for 2 hours, and cool to obtain a xylene solution of nitrogen-containing and sulfur-containing polymers.

[0034] Preparation of high-temperature corrosion inhibitor——Add 58 grams of the nitrogen-cont...

Embodiment 3

[0036] Preparation of nitrogen-containing sulfur-containing polymer——Put 105 grams of cetyl succinic acid and 100 grams of xylene into a 500-ml four-necked flask equipped with a stirrer, a thermometer, a water separator and a condenser. Turn on the condensed water while using the stirring device, then slowly add 10 g of aminobenzothiazole, heat up until the xylene starts to reflux, and react for 3 hours. Then 80 g of tetraethylenepentamine was added dropwise, and after reacting for 1 hour, the temperature was raised to 220° C., dehydrated, solvent removed, and cooled to 100° C. after constant temperature for 5 hours. Then add 200 grams of xylene and 15 grams of hexadecyl succinic acid, heat up until the xylene begins to reflux, react for 2 hours, and cool to obtain a xylene solution of nitrogen-containing and sulfur-containing polymers.

[0037] Preparation of high-temperature corrosion inhibitor——Add 46 grams of the nitrogen-containing and sulfur-containing polymer solution p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com