Method for continuously preparing iodine pentafluoride

A technology of iodine pentafluoride and fluorine gas, applied in the direction of interhalogen compounds, etc., can solve the problems of inability to carry out continuous operation, limited production efficiency, etc., and achieve the effects of reducing investment costs, controllable reaction temperature, and facilitating industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

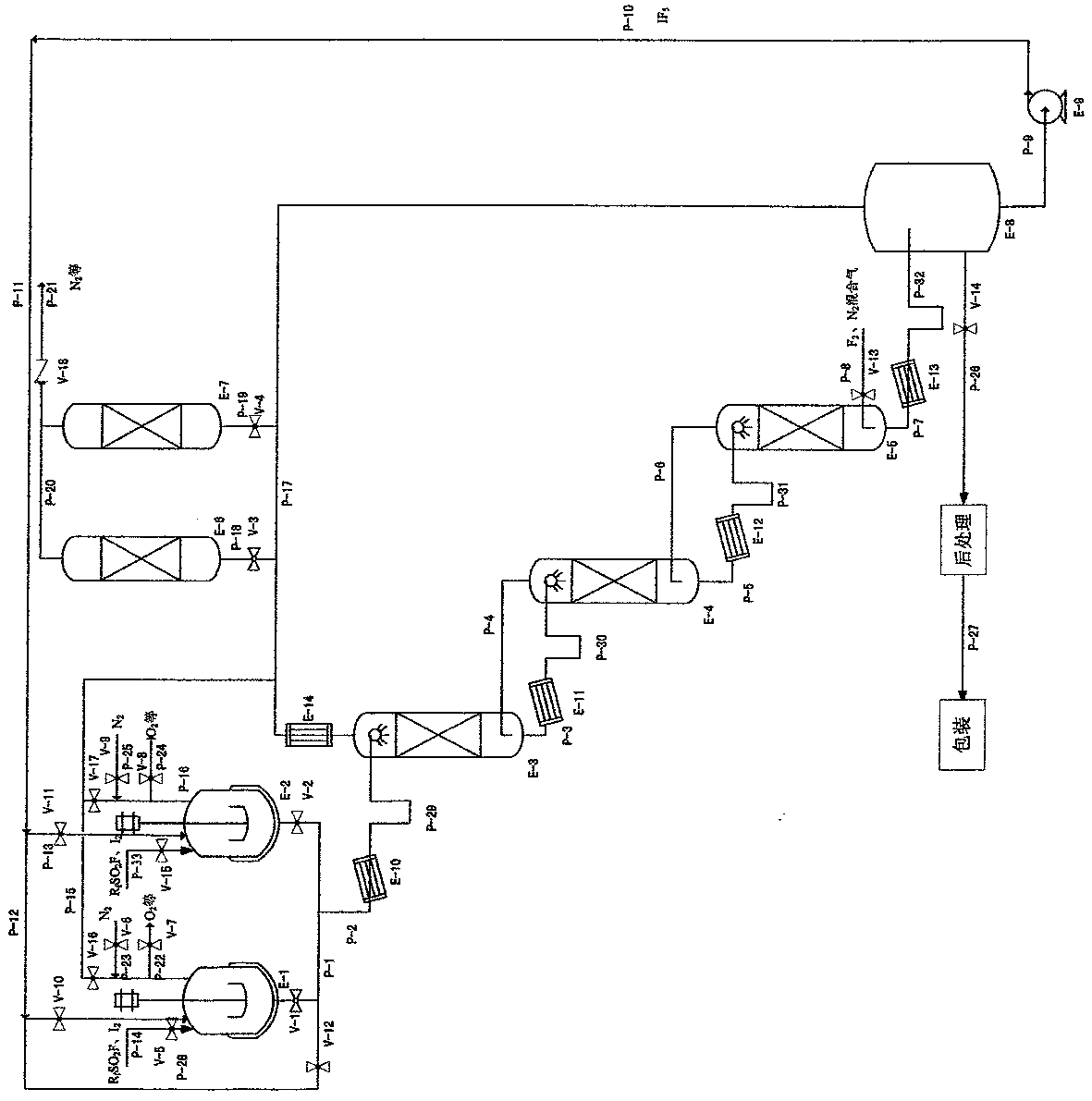

[0027] according to figure 1 As shown, the method for the continuous preparation of iodine pentafluoride of the present invention adopts a series process flow of multi-stage tower reactors. According to the process requirements, the number of towers can be 1 to N levels, and N≥3; f SO 2 F(R f Represents a perfluoroalkyl chain, with carbon atoms ranging from 1 to 12), iodine solution (iodine pentafluoride as a solvent) and fluorine gas or fluorine-nitrogen mixed gas enter the multi-stage reaction tower from both ends to react in reverse flow . The heat absorbed when dissolving iodine and the heat generated in the reaction are taken out through the condenser between the towers, and the reaction tower and the condenser are connected by U-shaped pipes. The purpose of liquid sealing is achieved through the U-shaped tube, because it is filled with iodine solution during the reaction, and the U-shaped tube can prevent fluorine gas from entering the iodine solution pipeline to achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com