Hydraulic pump assembly of turnover device for automobile cab

A technology of overturning device and cab, which is applied to the upper structure of the truck, vehicle parts, transportation and packaging, etc., and can solve the problems of safety hazards, stopping and keeping the cab in the lowered position, complex structure, etc. Achieve the effect of good sliding seal and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the advantages of the present invention and its contribution relative to the prior art will be further clarified.

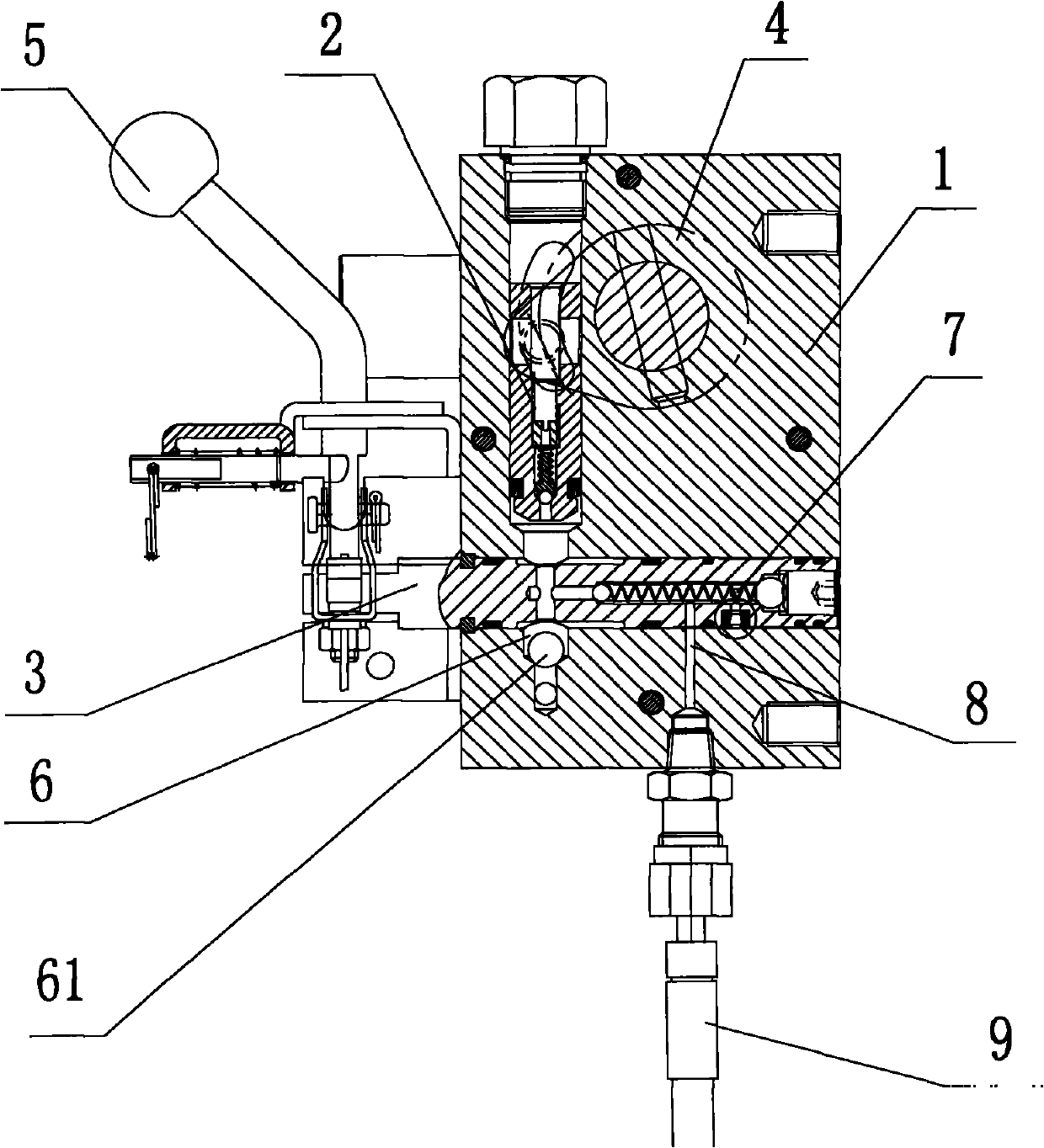

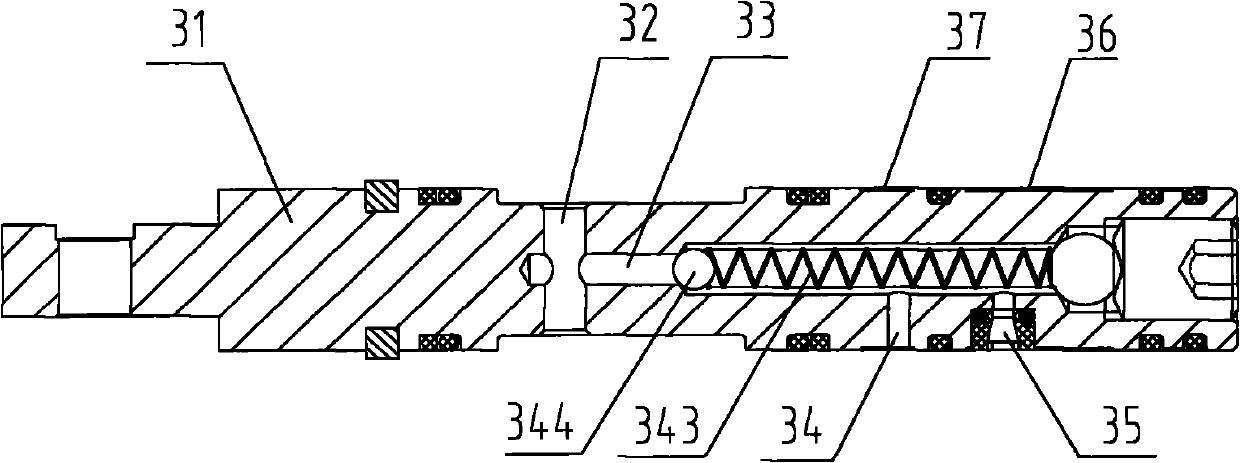

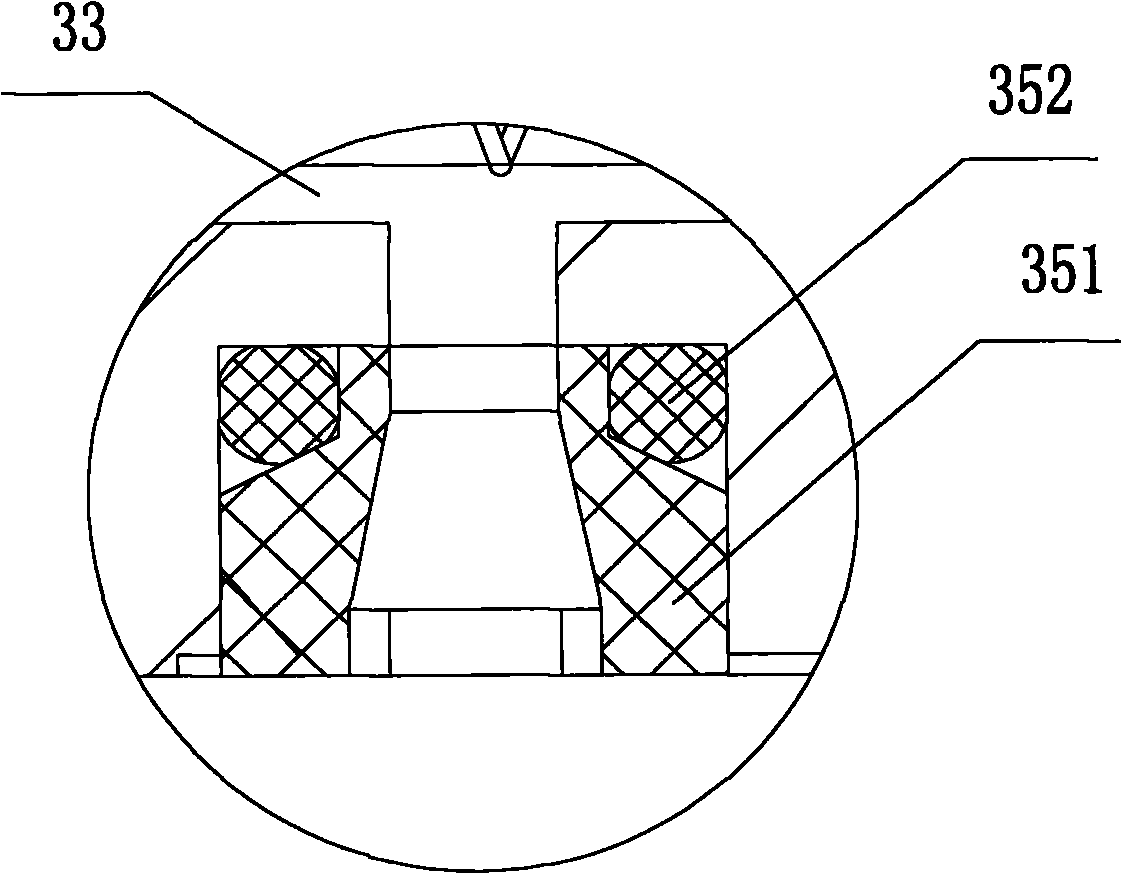

[0033] Such as figure 1 , 2, 3, and 4, one side of the pump body 1 is integrated with the fuel tank 10, and the inside of the pump body 1 is longitudinally integrated with a plunger 2 that slides and seals with the inner wall of the pump body. There is a spherical one-way valve core C21 inside, the spherical one-way valve core C21 is usually a steel ball, the ball seat 22 for fixing the steel ball, the return spring B23 for pressing the ball seat 22, and the screw plug 24 is provided with an oil return channel And threaded with the plunger 2 to compress the return spring B23, which is used to adjust and fix the pressure value of the return spring B23; the rocker arm 4 is integrated on the outside of the pump body 1 and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com