Device for measuring cutting force and cutting temperature of cutter holder type rotary milling blade

A temperature measurement and cutting force technology, applied in the direction of measuring/indicating equipment, metal processing equipment, metal processing machinery parts, etc., can solve the problems of short response time, strict requirements on quality and size, high cost, etc., and achieve easy preparation and assembly , high measurement accuracy and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

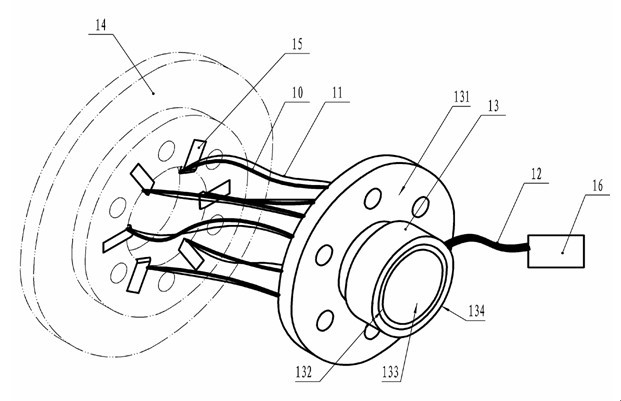

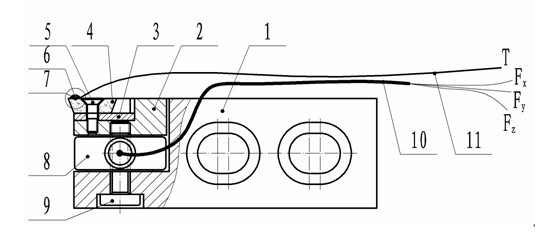

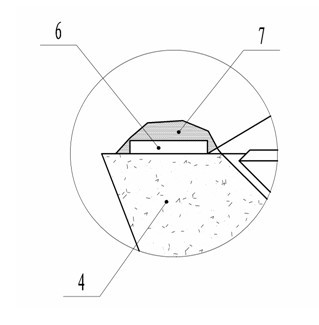

[0015] combine Figures 1 to 3 As shown in the figure, the cutting force and cutting temperature measuring device of the cutter bar type rotary milling insert proposed by the present invention includes a cutter bar 1, a three-way piezoelectric force sensor 8, a film temperature sensitive element 6 and a slip ring 13, and also includes a cutter seat 2. Cutter 3, blade 4, conical screw 5, bolt 9. Among them, the three-way piezoelectric force sensor 8 has a built-in charge amplification circuit, and the thin-film temperature sensitive element 6 adopts a platinum resistance temperature sensitive element.

[0016] combine figure 1 , figure 2 As shown, the signals detected by the three-way piezoelectric force sensor 8 and the thin-film temperature sensitive element 6 are connected to the input interface of the slip ring rotor by cables 10 and wires 11 respectively.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com