Tiled butting type ingot mold and casting method thereof

A technology of tiling butt joint and ingot mold is applied in the field of casting molds for ferroalloy production, which can solve the problems of hidden dangers, inconvenient installation of ingot molds, erosion and erosion, etc., and achieve the effect of ensuring safety performance and reducing labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

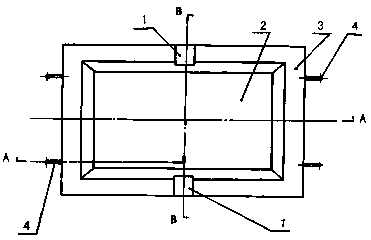

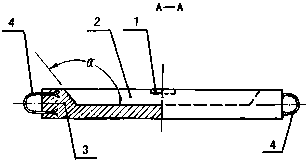

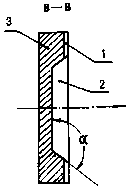

[0037] A flat butt joint ingot mold, which is mainly composed of a mold body 3 and a set of hoisting rings 4 fixedly installed on the mold body 3, and the inner end of the hoisting ring 4 is set as a pawl structure 5, which has good installation and stability performance , said one set of hoisting rings 4 can be installed on the outer end surface position of the mold body 3, and a set of hoisting rings 4 can also be installed on the top surface position of the mold body 3, and the said mold body 3 is provided with an inner wall surface to form an outer inclined structure The casting cavity 2 has a length of 2000mm, a width of 1200mm, and a depth of 200mm, and the controlled external inclination angle α is 135o. A molten iron overflow groove 1 is respectively arranged on the opposite side wall of the cavity 2, and a molten iron overflow groove 1 can also be a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com