Process for recycling gold from high-arsenic and high-sulfur difficultly treated gold ore

A gold recovery technology for refractory gold ore, applied in the field of gold recovery, can solve the problems of low concentrate grade, low recovery rate, and inability to obtain qualified gold concentrate, and achieve the goal of improving the gold concentrate grade and increasing the utilization rate of sulfur Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] The new process was applied to a high arsenic and high sulfur refractory gold mine. The metal minerals in a high-arsenic and high-sulfur gold mine in Anhui are mainly pyrite (partially fragmented and altered into colloidal pyrite), pyrrhotite, arsenopyrite, etc. A small amount of sphalerite, sphalerite, etc. Galena, chalcopyrite and other metal sulfides; there are few gangue minerals, mainly carbonate minerals calcite and dolomite, followed by clay minerals, altered minerals chlorite and sericite, and a small amount of quartz and feldspar Wait. The gold part is natural gold in the form of fine particles, most of which are closely symbiotic with arsenopyrite, colloidal pyrite and gangue, and are extremely difficult to dissociate. Generally speaking, the ore contains high arsenic and sulfur content, and gold is difficult to dissociate, which is a typical refractory gold ore.

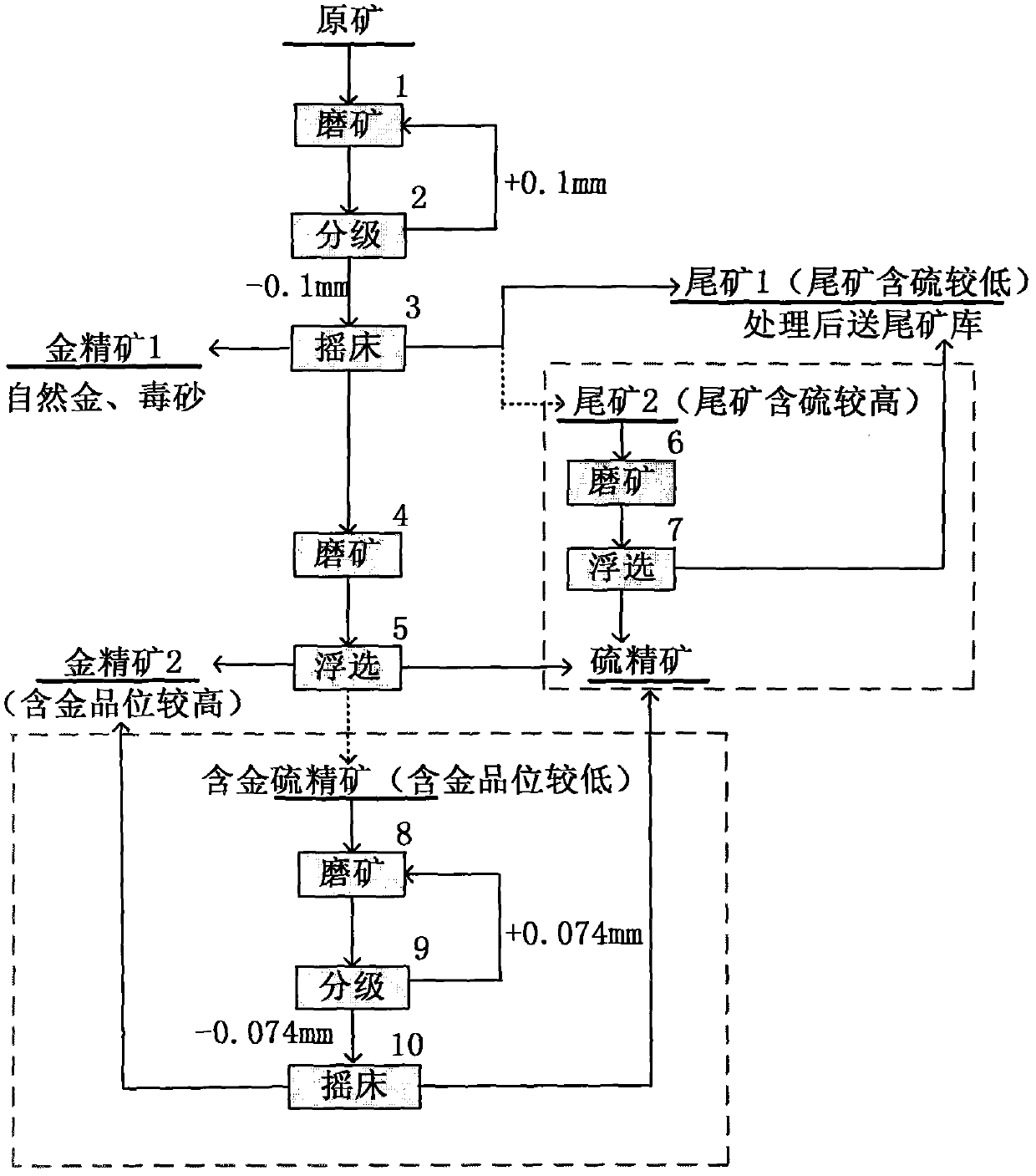

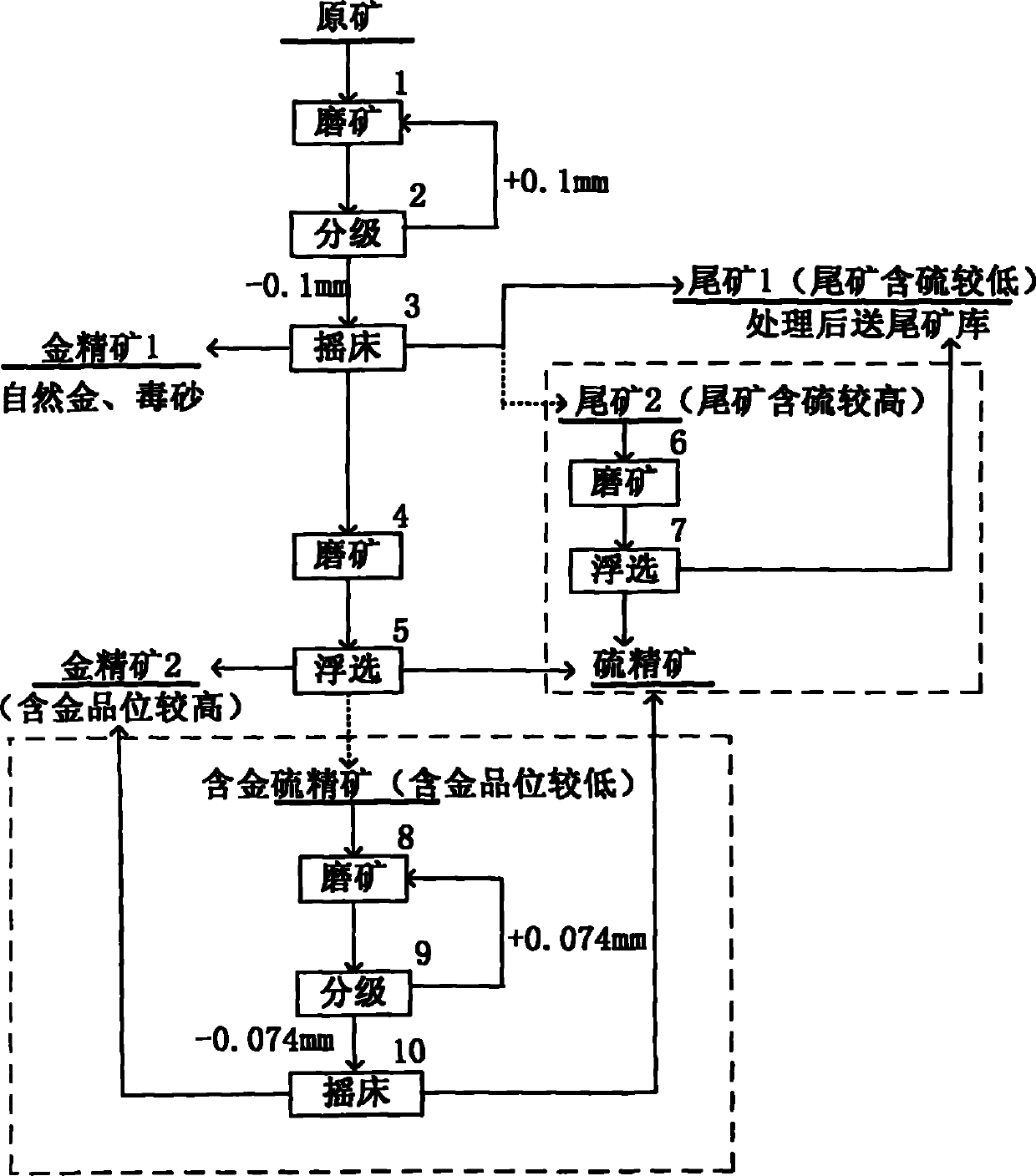

[0020] (1) As shown in the attached figure, the raw ore is first graded to -0.1mm by grinding,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com