Process and device for flue gas wet desulphurization using carbide slag or white clay as desulfurizing agent

A technology of wet desulfurization and calcium carbide slag, which is applied in the field of air pollution control technology, can solve the problems of slurry scaling, blockage of equipment, and affecting the use value of desulfurization gypsum, and achieve the effects of reducing sewage discharge and saving water costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

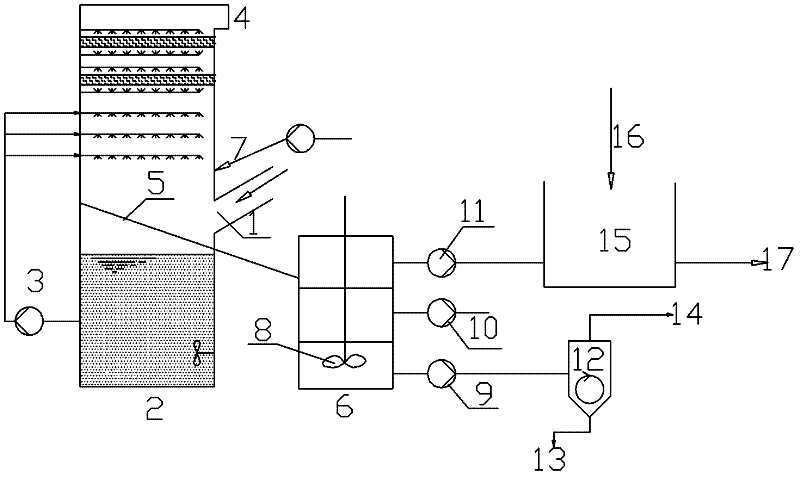

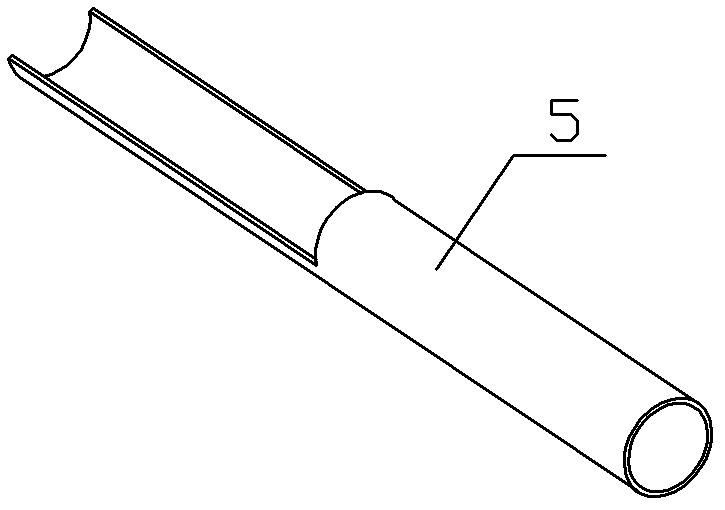

[0034] In a thermal power plant, two 240t / h boilers adopt the device and process of the present invention. The overall installation angle of the draft pipe is at an angle of 60° to the central axis of the absorption tower, and the cross-sectional area of the groove opening is 2% of the cross-sectional area of the absorption tower. The pH value of the desulfurization slurry in the tower is controlled between 5.0-5.4, and the desulfurization liquid-gas ratio is 8L / m 3 , the volume stirring power in the separation tank is 0.04KW / m 3 . The concentration of sulfur dioxide in the imported flue gas is 4300mg / m 3 , the outlet flue gas sulfur dioxide concentration is 96mg / m 3 , the purity of gypsum is 97.2%, the moisture content of gypsum is 9.5%, and the content of heavy metal ions in gypsum is 0.01%.

Embodiment 2

[0036] In a thermal power plant, two 130t / h boilers adopt the desulfurization device and process of the present invention. The overall installation angle of the draft pipe and the central axis of the absorption tower form an angle of 52.5°, and the opening cross-sectional area of the groove is 1.5% of the cross-sectional area of the absorption tower. , the pH value of the desulfurization slurry in the absorption tower is controlled between 5.0-5.4, and the desulfurization liquid-gas ratio is 7L / m 3 , the volume stirring power in the separation tank is 0.05KW / m 3 . The concentration of sulfur dioxide in the imported flue gas is 5160mg / m 3 , the outlet flue gas sulfur dioxide concentration is 108mg / m 3 , the purity of gypsum is 96.1%, the moisture content of gypsum is 9.7%, and the content of heavy metal ions in gypsum is 0.01%.

Embodiment 3

[0038] An enterprise has its own thermal power plant, four 75t / h boilers adopt the invented desulfurization device and process, the overall installation angle of the drainage pipe is at an angle of 60° to the central axis of the absorption tower, and the cross-sectional area of the groove opening is 2.1 of the cross-sectional area of the absorption tower %, the pH value of the desulfurization slurry in the absorption tower is controlled between 5.0-5.4, and the desulfurization liquid-gas ratio is 9L / m 3 , the volume stirring power in the separation tank is 0.06KW / m 3 . The concentration of sulfur dioxide in the imported flue gas is 2880mg / m 3 , the outlet flue gas sulfur dioxide concentration is 53mg / m 3 , the purity of gypsum is 95.4%, the moisture content of gypsum is 10.2%, and the content of heavy metal ions in gypsum is 0.01%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com