Improved screw head

一种螺钉头、螺钉的技术,应用在螺钉、拉伸载荷作所特别改进的连接件、螺纹紧固件等方向,能够解决削弱系统、移植物和/或基牙厚度的等量减少、总尺寸不能改变等问题,达到减少摩擦的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

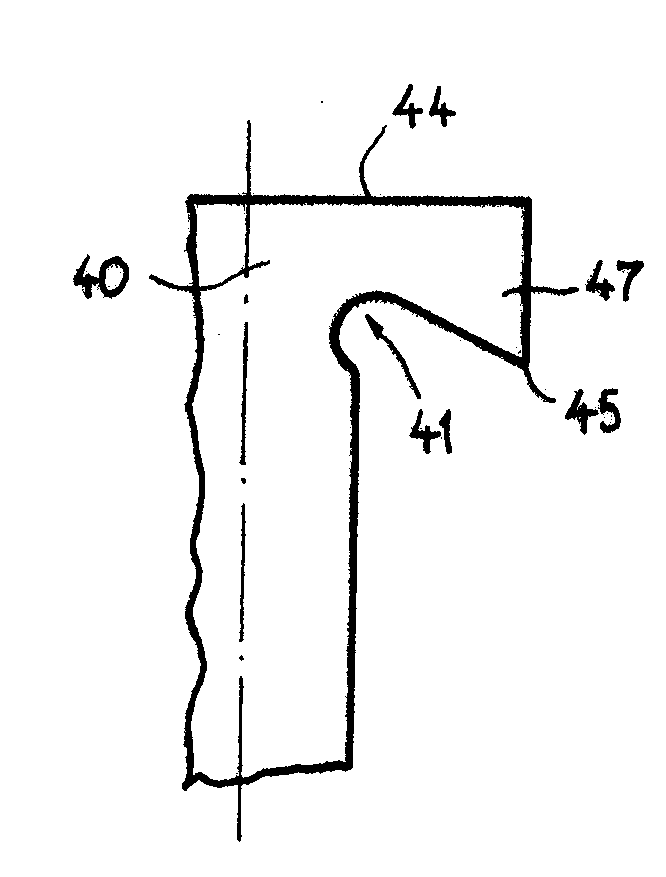

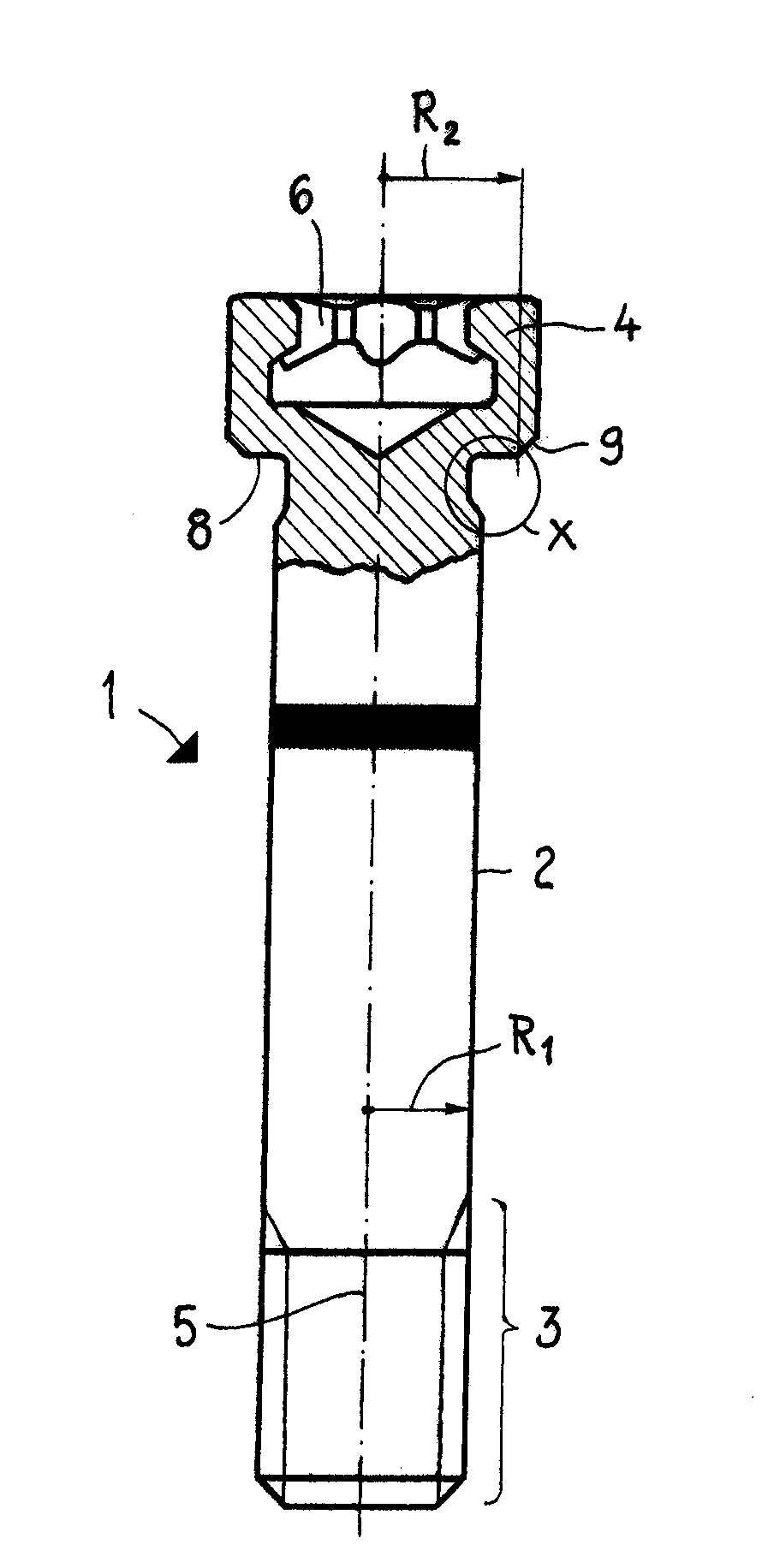

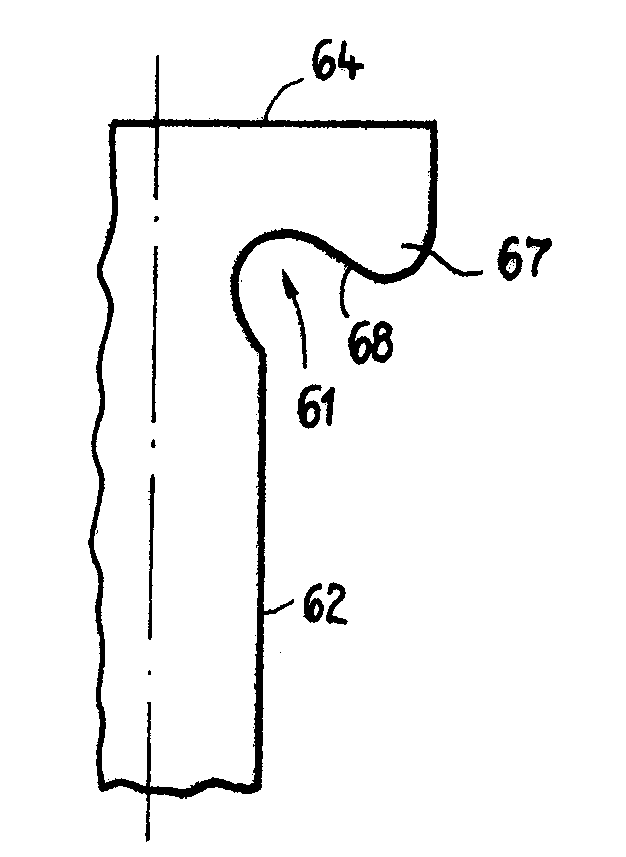

[0077] Figure 1A and B show a base screw 1 according to a prior art system. It comprises a screw shaft 2 extending along a longitudinal axis 5 . At its distal end, the shaft 2 includes a threaded portion 3, the size and pitch of which are selected to engage the internally threaded hole of the implant. At its opposite end, the shaft 2 is connected to the screw head 4 . The head 4 contains in its coronal end a hollow 6 shaped to allow the insertion of a driving tool such as a screwdriver. The hollow 6 has a non-circular symmetrical profile enabling torque to be transmitted from the driving tool to the screw 1 .

[0078] The maximum radius R of the bottom or top of the head 4 2 Greater than the maximum radius R of axis 2 1 . This results in an annular contact surface formed by the underside 8 of the screw head 4 . Since the abutment or other member to which the screw engages must include a screw channel dimensioned to allow passage of the screw shaft 2, the maximum possibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com