Application of low-carbon saving type pig house

An economical, pig house technology, applied in the application, animal house, animal husbandry and other directions, to achieve the effect of good dust removal, low construction cost and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing the implementation details of the present invention are described as follows:

[0044] An application of a low-carbon, energy-saving and environmentally friendly pig house, including pig house sheds and pig house internal facilities.

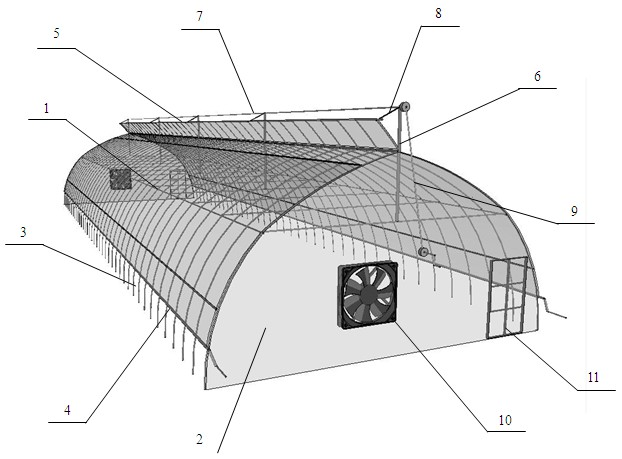

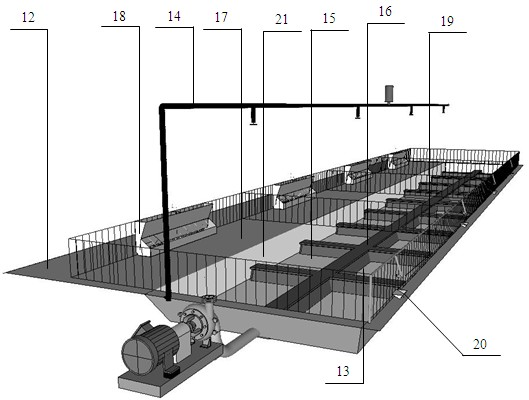

[0045] Such as figure 2 As shown, the pig house greenhouse adopts a galvanized steel pipe greenhouse structure with a width greater than 8m and a height greater than 4m. The surface of the gable (2) light-transmitting film on the wall is covered with a black sunshade net to shield the strong light; the bottom of the wall on the north and south sides of the pig house shed is equipped with an openable and closed vent (3) with a height of about 1.2-1.8m. 4) Adjust the opening and closing height of the plastic light-transmitting film to control the ventilation area on both sides; the roof of the shed is equipped with an openable and closable ventilation skylight facing south, and the ventilatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com