Edible fungus liquid strain inoculation and injection gun

A technology for liquid strains and edible fungi is applied in the fields of application, horticulture, and botanical equipment and methods. Reduced preparation time, improved inoculation efficiency, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

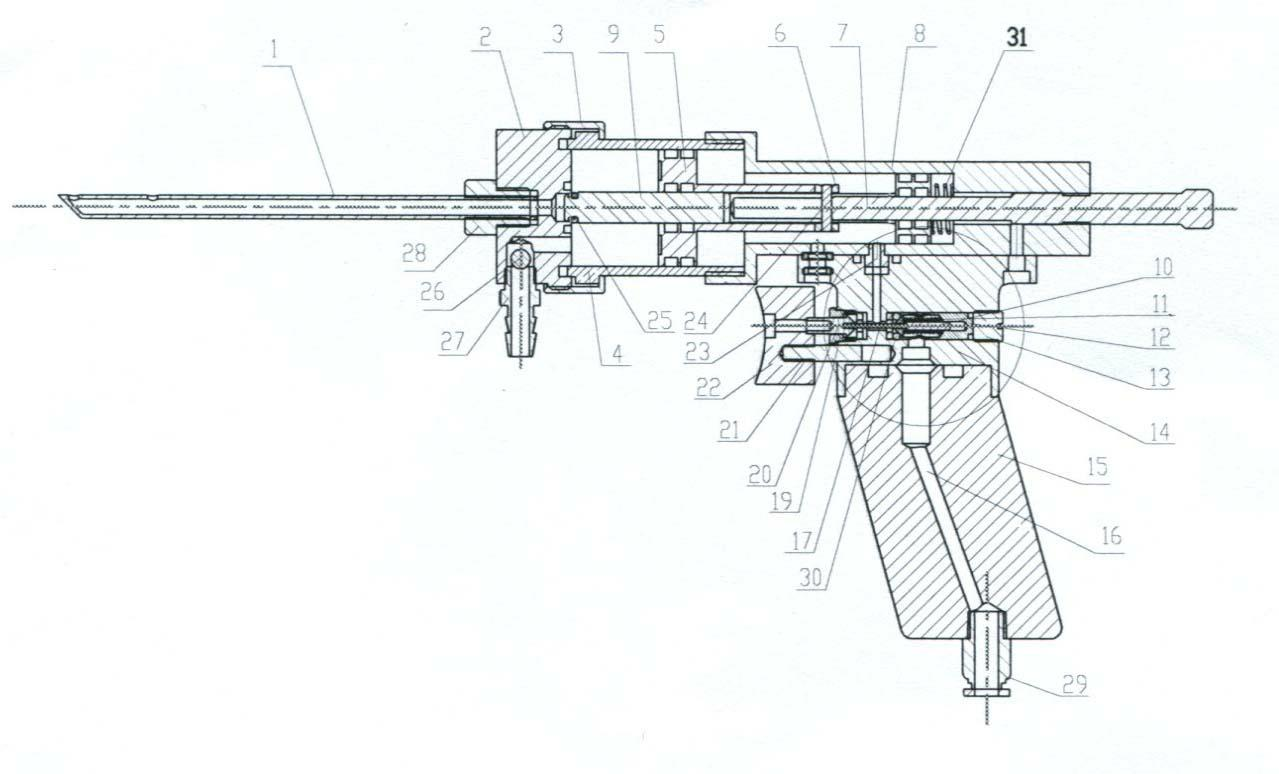

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

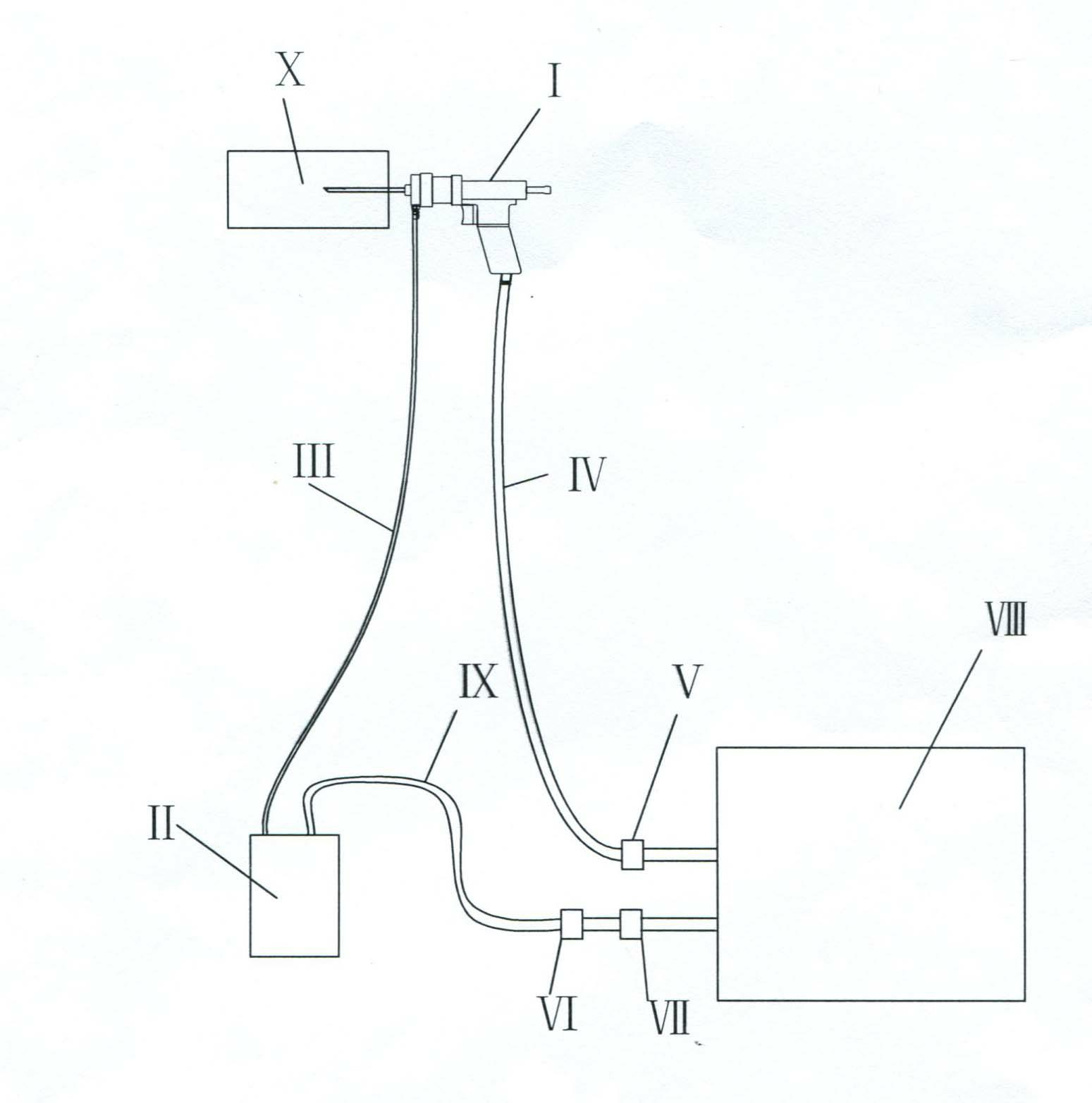

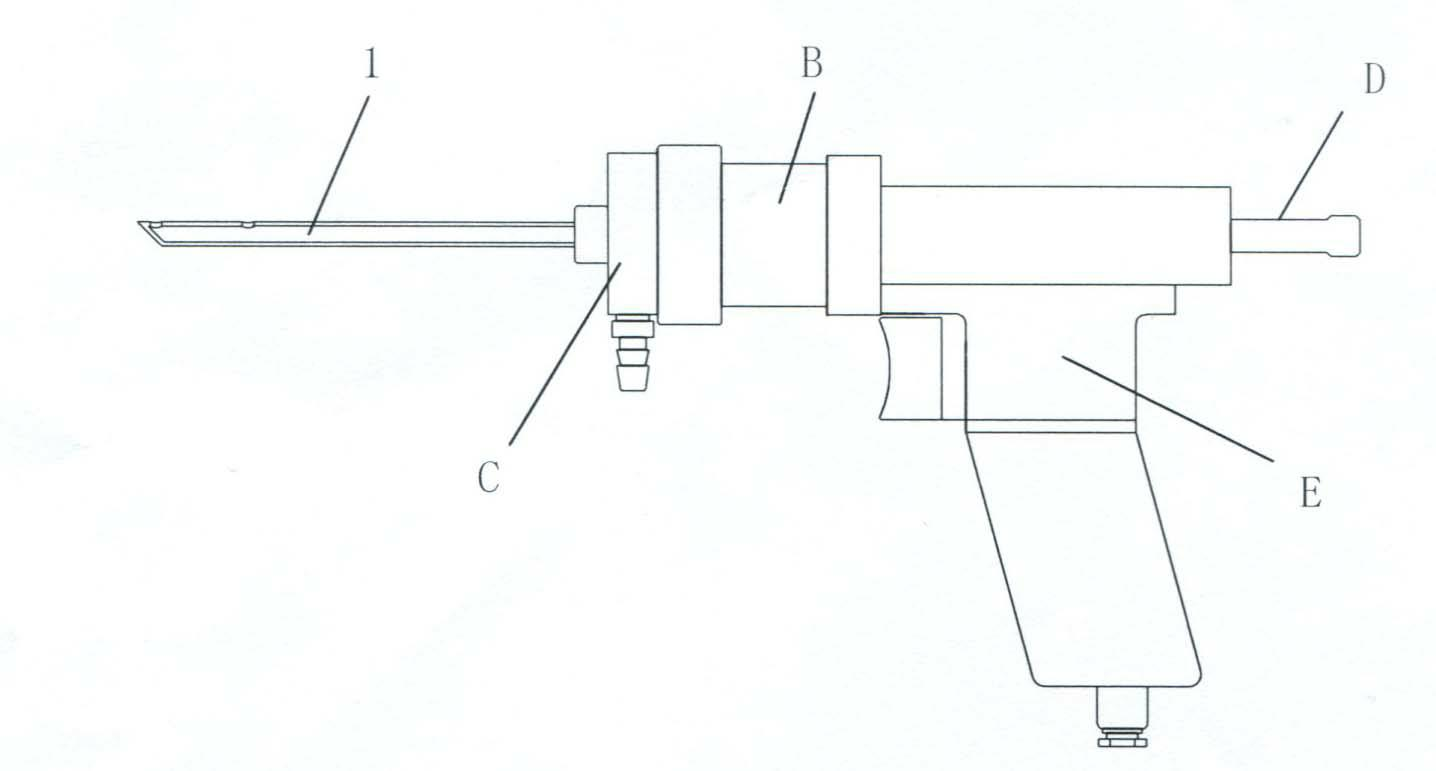

[0019] figure 1 As shown, the edible fungus liquid strain inoculation system of the present invention includes edible fungus liquid strain inoculation injection gun I, liquid strain tank II, liquid strain delivery pipe III, high-pressure air pipe IV, high-pressure air pressure regulating valve V, filter Ⅵ. Pressure reducing valve Ⅶ, air pump Ⅷ and air pipe Ⅸ; the output pipe of the air pump Ⅷ is connected to the quick joint of the edible fungus liquid strain inoculation injection gun Ⅰ through the high-pressure air pressure regulating valve Ⅴ and the high-pressure air pipe Ⅳ, and the output of the air pump Ⅷ The tube is connected to the liquid strain tank II through the pressure reducing valve VII, the filter VI and the air supply pipe IX; the liquid strain tank II is connected to the liquid feed of the edible fungus liquid strain inoculation injection gun I through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com