Threshing device of harvester

A technology of threshing device and harvester, which is applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of shortened harvester life, increased grain loss rate, high threshing loss rate, etc., to achieve low threshing loss rate, threshing Fast speed and high threshing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

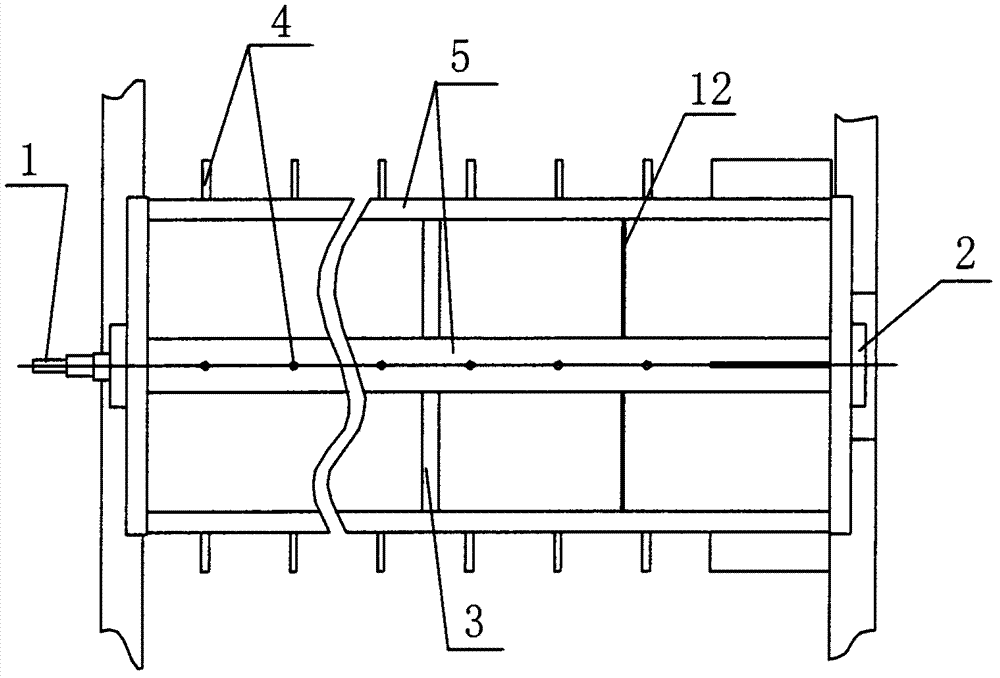

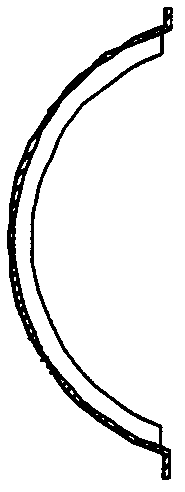

[0024] Embodiment 1 refers to appended figure 1 , 4 And 5, a harvester threshing device, comprising a main shaft 1, a bearing seat 2, a toothed nail 4, a reinforcement ring 3, a toothed nail fixing angle steel 5, a feed port 8, a discharge port 9, an upper cover 10 and a lower cover 11, It is characterized in that a threshing disc 12 is set on the main shaft 1 with the main shaft 1 as the center of the circle, the threshing disc 12 is fixedly connected with the nail fixed angle steel 5, and the distance between the threshing disc 12 and the right end of the feeding port 8 is 801 The distance is 440mm, and the distance from the right end 901 of the discharge port 9 is 80-100mm.

Embodiment 2

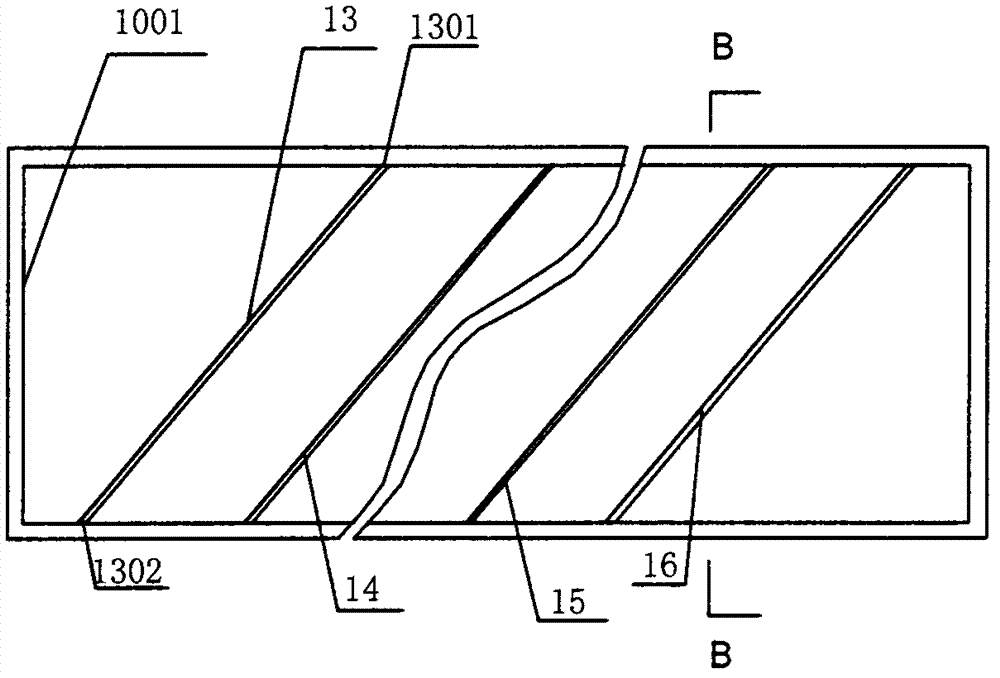

[0025] Embodiment 2 refers to the appended Figure 1-6 , a harvester threshing device, comprising a main shaft 1, a bearing seat 2, a toothed nail 4, a reinforcement ring 3, a toothed nail fixing angle steel 5, a feed port 8, a discharge port 9 and an upper cover 10, characterized in that: the main shaft 1 is the center of the circle. A threshing disc 12 is set on the main shaft 1. The threshing disc 12 is connected to the pinion fixing angle steel 5 by spot welding. The distance between the threshing disc 12 and the right end 801 of the feeding port 8 is 440mm , the distance from the right end 901 of the discharge port 9 is 80-100mm; the inner wall of the upper cover 10 is provided with a flat iron, the height of the flat iron is 20±2mm, the upper end 1301 of the flat iron 1 is 100-1200±2mm from the left side of the upper cover, and the lower end is 1302 The left side of the upper cover is 100190±2mm, the flat iron II 14, the flat iron III and the flat iron IV15 are arranged ...

Embodiment 3

[0026] Embodiment 3 is with reference to attached Figure 2-8 , a harvester threshing device, comprising a main shaft 1, a bearing seat 2, a toothed nail 4, a reinforcement ring 3, a toothed nail fixing angle steel 5, a feed port 8, a discharge port 9 and an upper cover 10, characterized in that: the main shaft 1 is the center of the circle, and a threshing disc 12 is arranged on the main shaft 1, and the threshing disc 12 is fixedly connected with the nail fixing angle steel 5, and the distance between the threshing disc 12 and the right end 801 of the feeding port 8 is 440mm, and the distance The distance between the right end 901 of the discharge port 9 is 80-100mm; the inner wall of the upper cover 10 is provided with a flat iron, the height of the flat iron is 20±2mm, the upper end 1301 of the flat iron 1 is 1001200±2mm from the left side of the upper cover, and the lower end 1302 is 1302 from the upper cover Left side 100190±2mm, flat iron II 14, flat iron III and flat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com