Manufacturing method of circuit boards

A manufacturing method and circuit board technology, which are applied in the direction of electronic circuit testing, electrical connection formation of printed components, etc., can solve problems such as loss of circuit boards, difficult to accurately conduct through holes of circuit boards, etc., and achieve accurate conduction, Avoid the effects of destructive testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The manufacturing method of the circuit board provided by the technical solution will be further described in detail below in conjunction with multiple drawings and embodiments.

[0073] The circuit board manufacturing method provided by the embodiment of the technical solution includes the following steps:

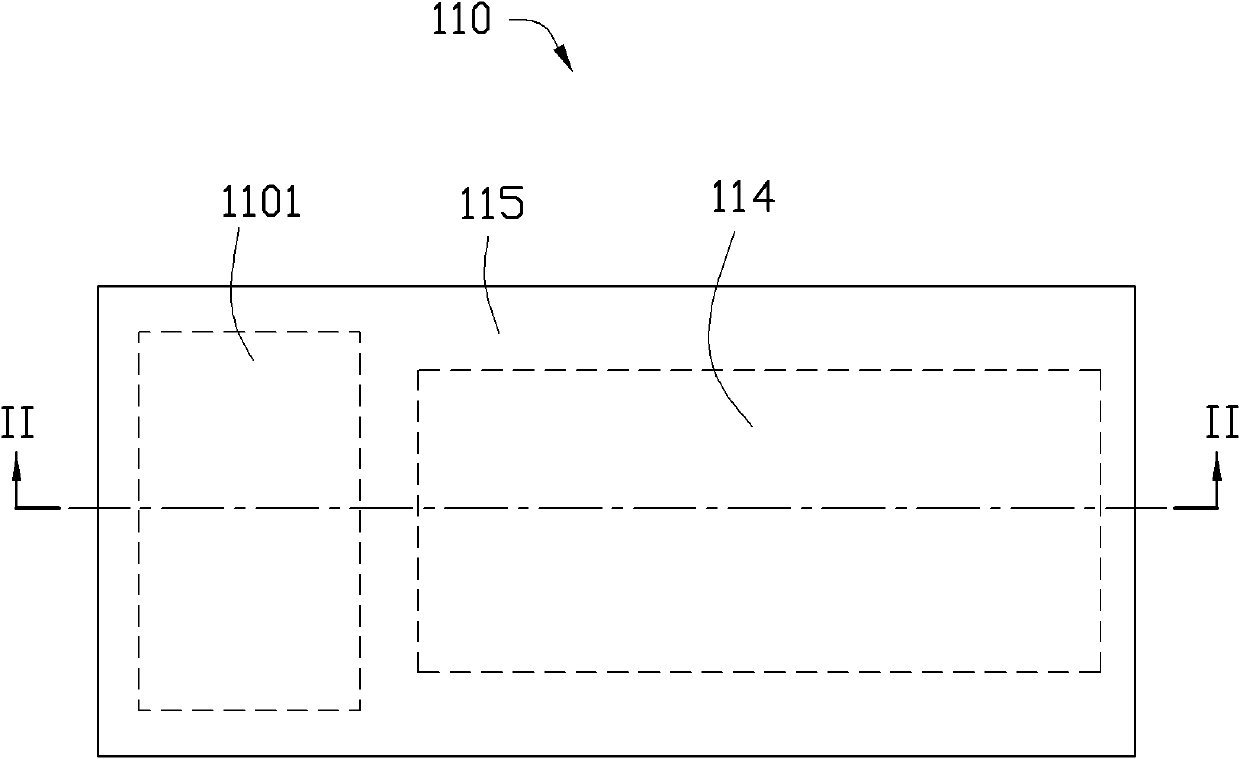

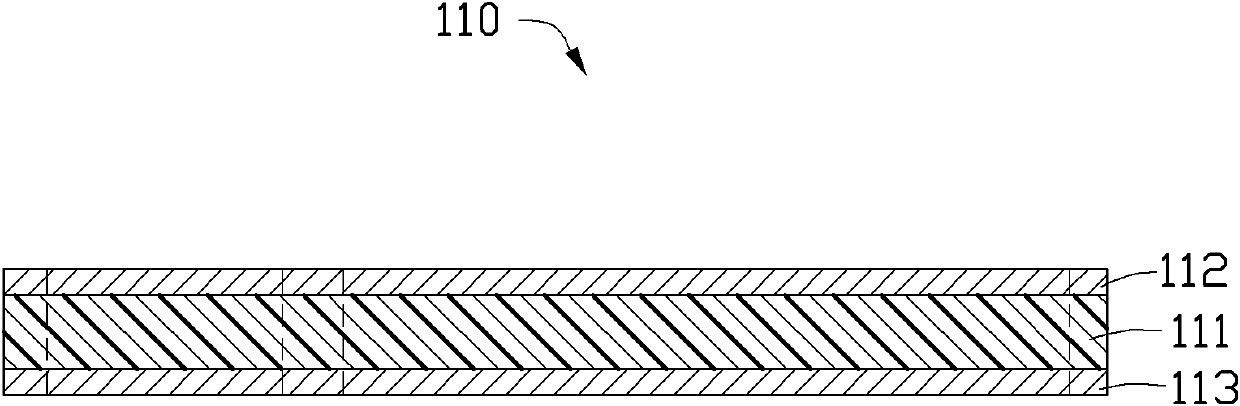

[0074] For the first step, please also refer to figure 1 with figure 2 , providing an inner layer substrate 110 .

[0075] The inner substrate 110 has a structure composed of conductive layers on both sides and an insulating layer between the two conductive layers. In this embodiment, the inner substrate 110 is a double-sided copper-clad substrate, which includes an insulating layer 111 and a first copper foil layer 112 and a fourth copper foil layer 113 formed on opposite sides of the insulating layer 111 . The inner substrate 110 includes a product area 114 and a non-product area 115 . The product area 114 corresponds to the circuit board unit to be formed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com