Tightness detection device and detection method for torque converter

A technology for torque converter and tightness detection, which is used in machine sealing ring testing, liquid/vacuum measurement for liquid tightness, and measuring devices, etc., can solve the problem of limited reliability of test results, waste of cost, and low efficiency. and other problems to avoid destructive testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

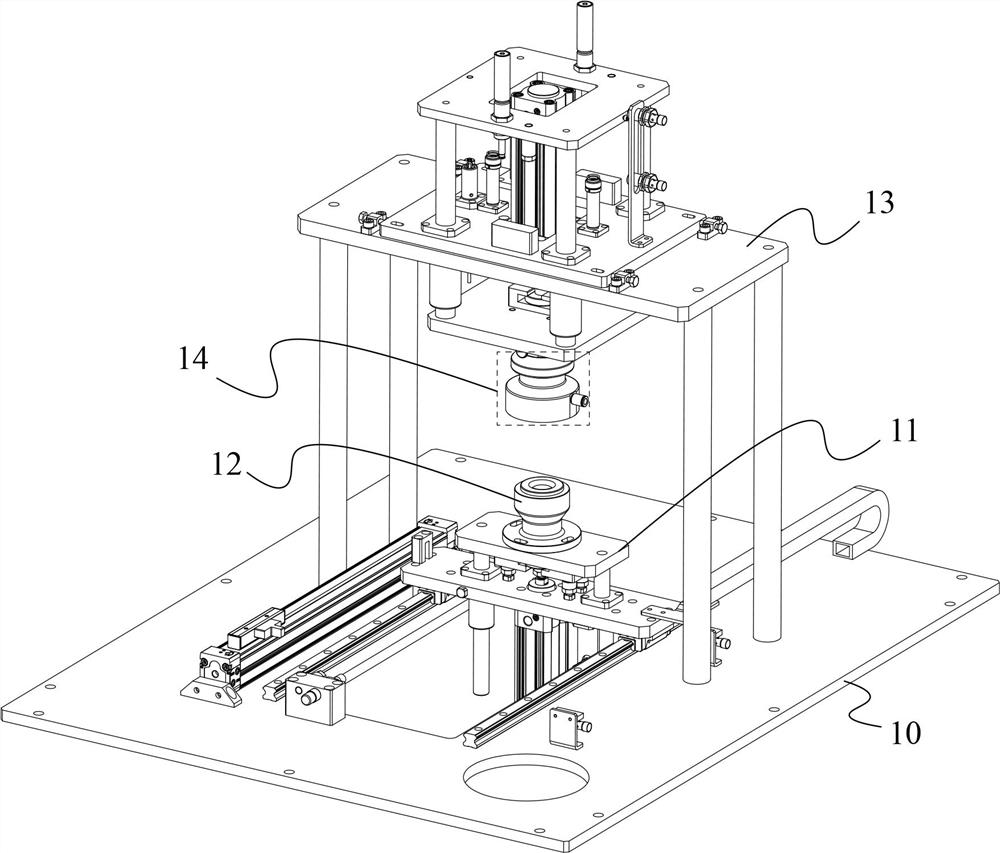

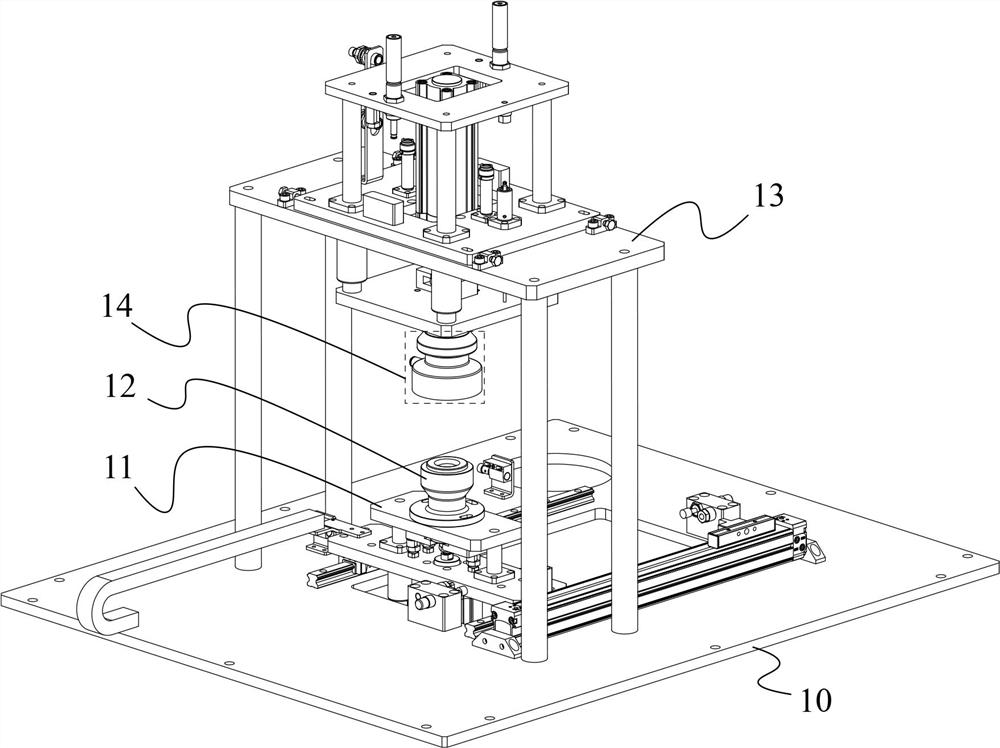

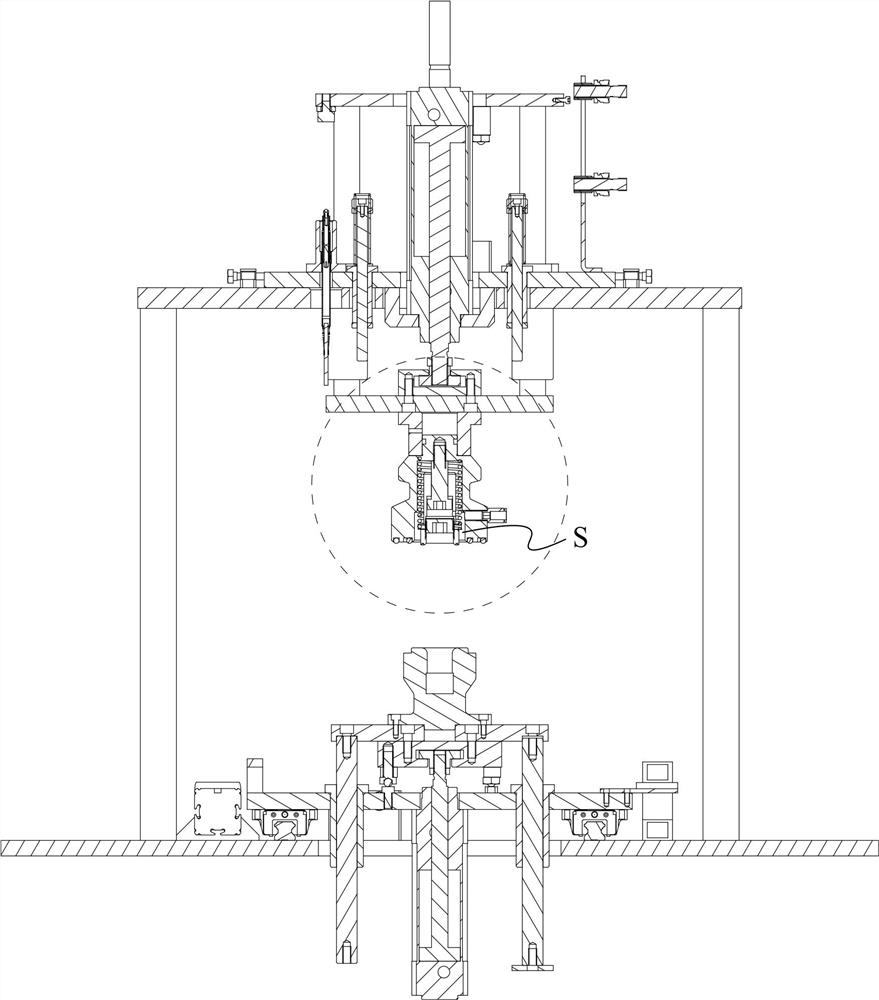

[0038] According to a preferred embodiment, the pressing mechanism 14 includes: a base part 141, the base part 141 is vertically movable mounted on the fixed bracket 13; and a pressing part 142, the pressing part 142 is mounted on the At the bottom of the base part 141, the cavity S1 of the press-down part 142 has a first port 143 open downward and the vacuum is carried out through the second port 144 arranged on the side wall, and the inside of the press-down part 142 It also includes a mandrel 145 , which is installed in the cavity S1 of the pressing part 142 in an elastically movable manner. The leak detection method further includes that after the vacuum degree in the enclosed space reaches a predetermined value, the press-down mechanism 14 no longer applies pressure to the hydraulic torque converter to be tested and / or no longer applies pressure to the hydraulic torque converter to be tested. Instead of evacuating the closed space, the closed space is completely closed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com