Permanent magnet direct-driven vernier motor

A vernier motor, direct-drive technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problem of large magnetic flux leakage and core loss , Difficult processing technology, limited power density and other problems, to achieve the effect of increasing output torque, compact structure and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

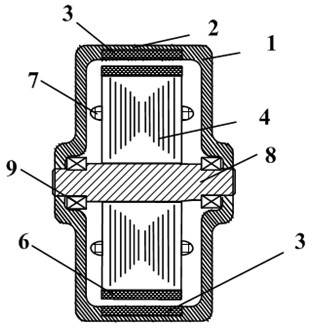

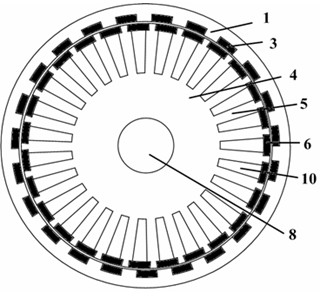

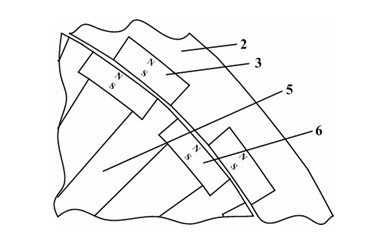

[0014] Such as Figure 1 to Figure 3 As shown, a permanent magnet direct drive vernier motor of the present invention includes an outer rotor 1 , an outer rotor permanent magnet 3 , a stator 4 , a stator permanent magnet 6 , a winding 7 , a motor shaft 8 and a bearing 9 . The outer rotor 1 is located outside the stator 4 . That is, the stator 4 is located inside the outer rotor 1 . The outer rotor 1 is rotatably connected to the motor shaft 8 through a bearing 9 . The bearing 9 is fixed on the inside of the outer rotor 1 , and the two ends of the motor shaft 8 are respectively located in one bearing 9 , and the outer rotor 1 can rotate around the motor shaft 8 . The motor shaft 8 is fixedly connected with the stator 4 . Since the motor shaft 8 is fixedly connected to the stator 4 , the outer rotor 1 can rotate around the stator 4 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com