Surface-carbon-modified cathode material of lithium ion battery and method for preparing surface-carbon-modified cathode material

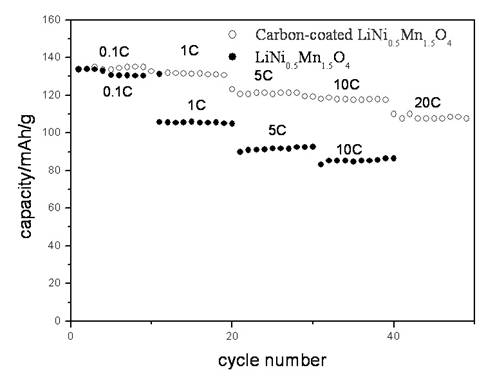

A lithium-ion battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of low rate performance of materials, and achieve the effects of excellent rate performance, simple operation, and increased specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

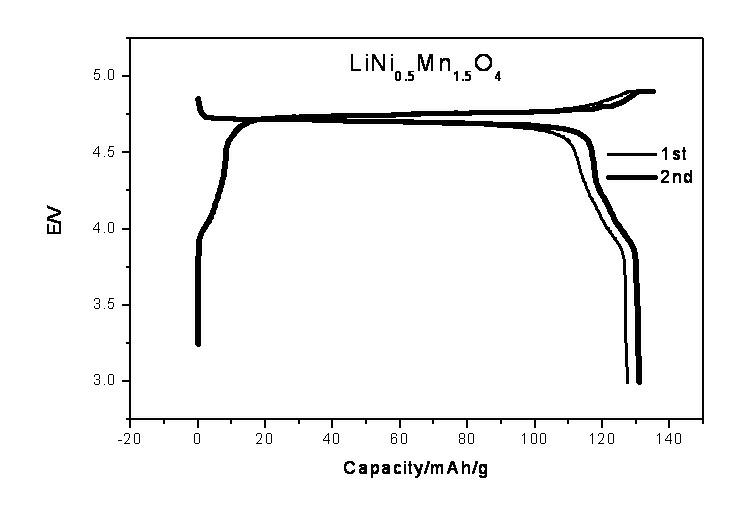

[0024] 0.05 mol of lithium acetate, 0.025 mol of nickel acetate, and 0.0725 mol of manganese acetate were mixed uniformly in a mortar and ground to obtain a light blue mixture. Then pre-fired at 580°C in a muffle furnace for 5 hours, and the heating rate was 5°C / min. After pre-burning, a reddish-brown precursor was obtained. First calcined, the heating rate is 10 / min, and kept at 850 ° C for 8 hours, then annealed at 700 ° C for 10 hours, and then cooled with the furnace to obtain black LiNi 0.5 mn 1.5 o 4 Material.

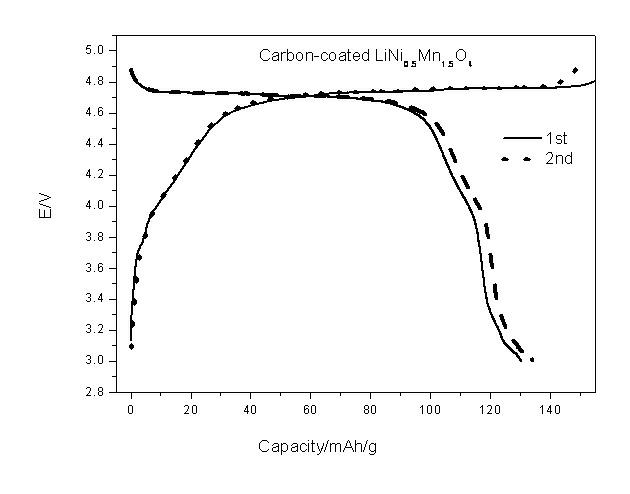

[0025] Add LiNi in water at a molar ratio of 1:5:1:2 0.5 mn 1.5 o 4 , cetyltrimethylammonium bromide, resorcinol and formaldehyde solution, then add a small amount of sodium carbonate, stir evenly at 80°C and react for 15 minutes to obtain LiNi coated with aldol resin on the surface 0.5 mn 1.5 o 4 Material, filter washed, dried LiNi 0.5 mn 1.5 o 4 material, and then in the inert atmosphere of a tube furnace, carbonize aldol resin to obtain carbon-modif...

Embodiment 2

[0027] 0.05 mol of lithium acetate, 0.025 mol of nickel acetate, and 0.0725 mol of manganese acetate were mixed uniformly in a mortar and ground to obtain a light blue mixture. Then pre-fired at 580°C in a muffle furnace for 5 hours, and the heating rate was 5°C / min. After pre-burning, a reddish-brown precursor was obtained. First calcined, the heating rate is 10°C / min, and kept at 850°C for 8 hours, then annealed at 700°C for 10 hours, and then cooled with the furnace to obtain black LiNi 0.5 mn 1.5 o 4 Material.

[0028] Add LiNi in water at a molar ratio of 1:10:2:4 0.5 mn 1.5 o 4 , cetyltrimethylammonium bromide, resorcinol, formaldehyde solution, and then add a small amount of sodium carbonate, stir evenly at 80°C and react for 30 minutes to obtain LiNi coated with aldol resin on the surface 0.5 mn 1.5 o 4 Material, filter washed, dried LiNi 0.5 mn 1.5 o 4 materials, and then in the inert atmosphere of a tube furnace, carbonize aldol resin to obtain carbon-modi...

Embodiment 3

[0030] 0.05 mol of lithium acetate, 0.025 mol of nickel acetate, and 0.0725 mol of manganese acetate were mixed uniformly in a mortar and ground to obtain a light blue mixture. Then pre-fired at 580°C in a muffle furnace for 5 hours, and the heating rate was 5°C / min. After pre-burning, a reddish-brown precursor was obtained. First calcined, the heating rate was 10°C / min, and kept at 850°C for 8 hours, then annealed at 700°C for 10 hours, and then cooled with the furnace to obtain black LiNi 0.5 mn 1.5 o 4 Material.

[0031] Add LiNi in water at a molar ratio of 1:15:3:6 0.5 mn 1.5 o 4 , cetyltrimethylammonium bromide, resorcinol and formaldehyde solution, then add a small amount of sodium carbonate, stir evenly at 80°C and react for 1 hour to obtain LiNi coated with aldol resin on the surface 0.5 mn 1.5 o 4 Material, filter washed, dried LiNi 0.5 mn 1.5 o 4 material, and then in the inert atmosphere of a tube furnace, carbonize aldol resin to obtain carbon-modified Li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com