Method for preparing hexagonal boron nitride interface coating

A technology of hexagonal boron nitride and interface coatings, which is applied in the field of preparation of hexagonal boron nitride interface coatings, can solve the problems of difficulty in forming uniform coatings, corrosion or toxicity, and high preparation costs, and achieve strong designability, Low oxygen content and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Select T300 2D plain woven carbon cloth, weave the fibers into 2D woven cloth in the directions of 0° and 90°, and laminate them to form a fiber prefabricated body with a size of 25mm×25mm×3mm as the base material ;

[0024] Step 2: Hang the fiber prefabricated body base material on the sample rack of the deposition furnace, and the sample rack is at the center of the isothermal zone in the furnace;

[0025] Step 3: Take BCl 3 -H 2 Preparation of elemental boron film on the substrate for the precursor, reaction temperature: 1000°C, holding time: 20 hours, furnace pressure: 400Pa;

[0026] Step 4: Carry out nitriding treatment on the preform containing boron coating in step 3, nitriding temperature: 1300°C, holding time: 10 hours, furnace pressure: 1000Pa, atmosphere is NH 3 -N 2 -H 2 , to get hexagonal boron nitride interface coating.

[0027] The fiber in step 1 is woven into a fiber prefabricated body with a size of 25mm×25mm×3mm as a base material by a ...

Embodiment 2

[0031] Step 1: Process the graphite into a block sample with a specification of 20mm×10mm×2mm as the base material, grind and polish the surface of the substrate, use alcohol to ultrasonically clean the substrate, and use it after drying;

[0032] Step 2: Hang the graphite base material on the sample holder of the deposition furnace, and the sample holder is at the center of the isothermal zone in the furnace;

[0033] Step 3: Take BCl 3 -H 2 Preparation of elemental boron film on the substrate as a precursor, reaction temperature: 900°C, holding time: 60 hours, furnace pressure: 1000Pa;

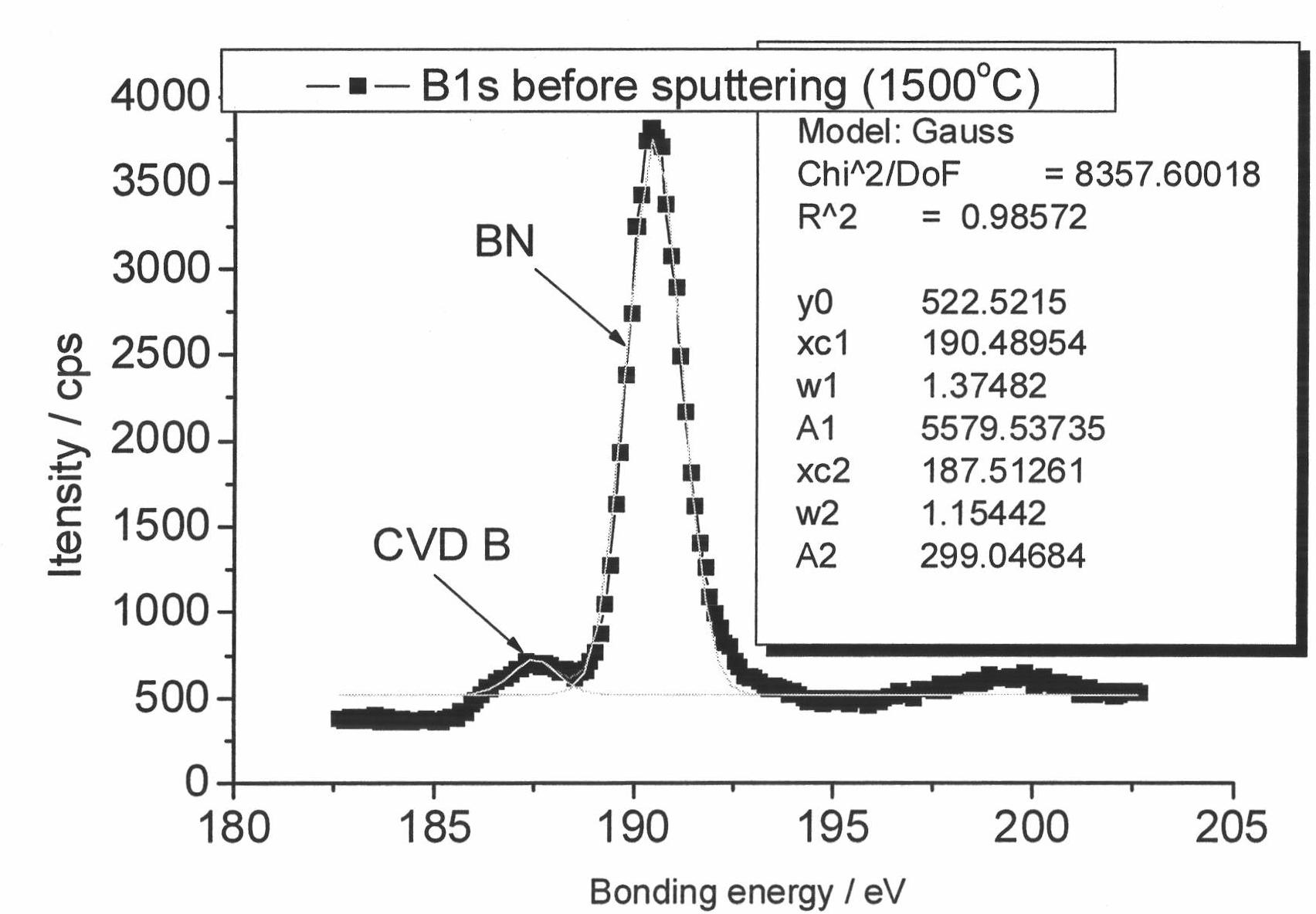

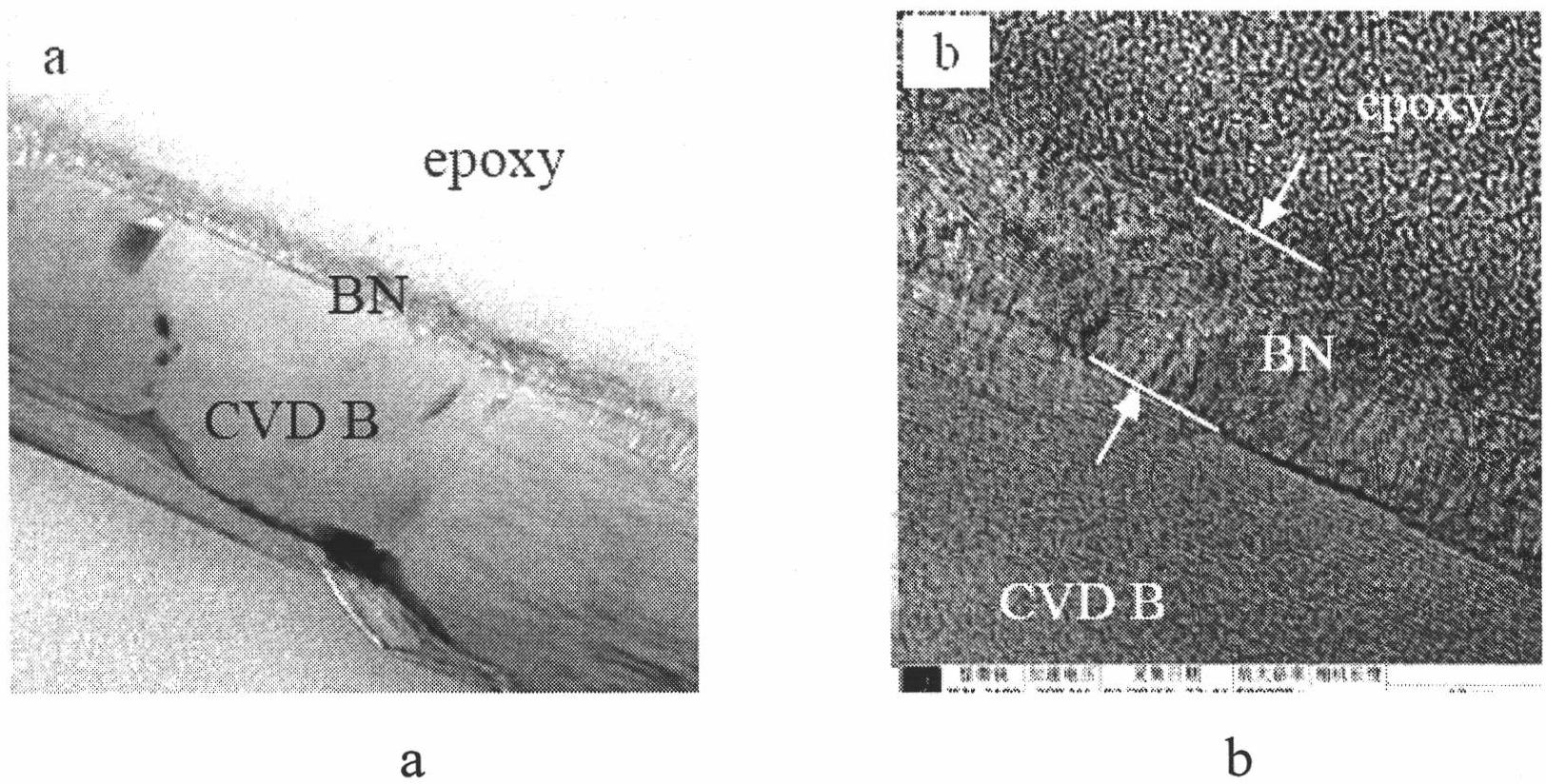

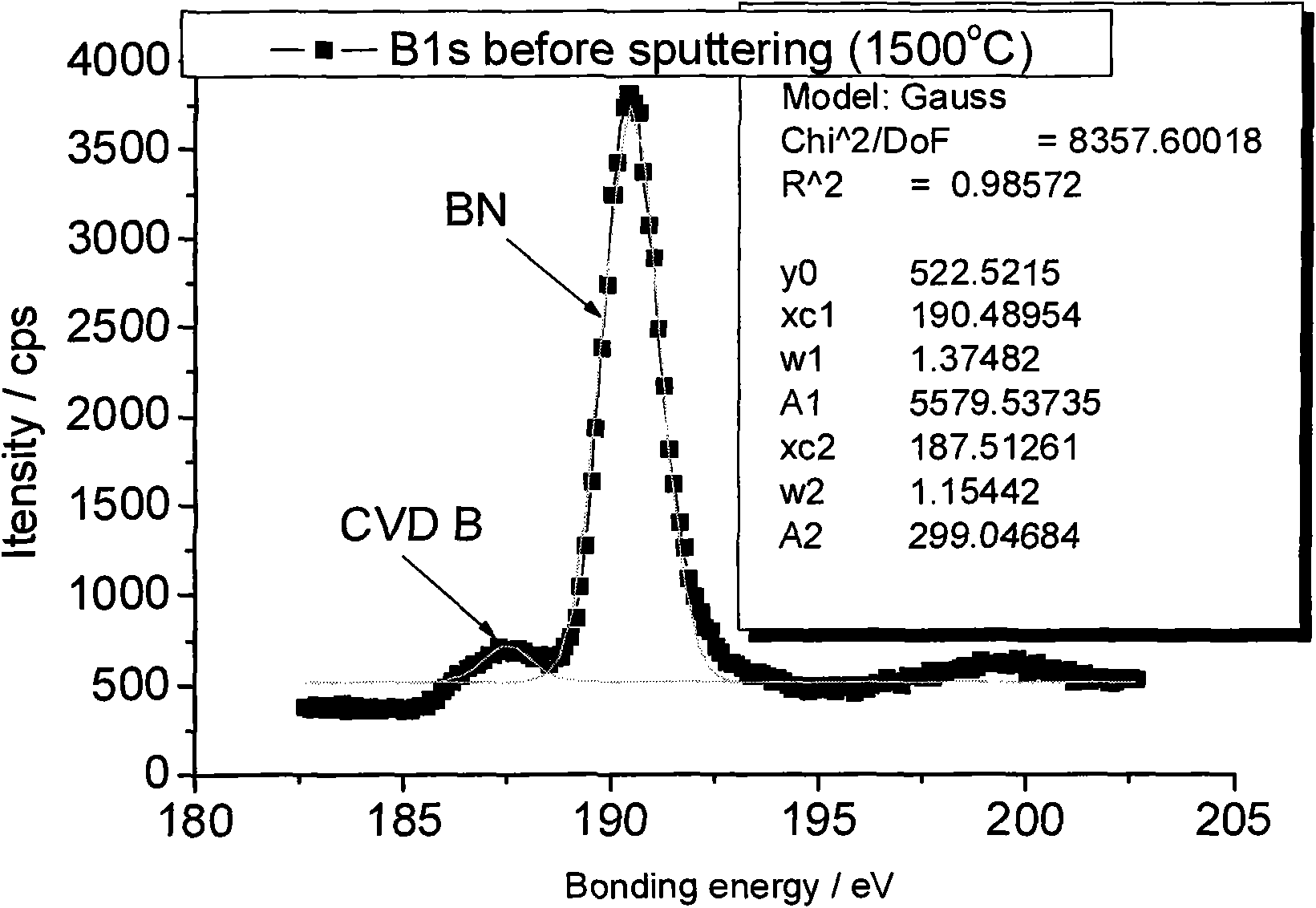

[0034] Step 4: Perform nitriding treatment on the preform containing boron coating in step 3, nitriding temperature: 1500°C, holding time: 10 hours, furnace pressure: 400Pa, atmosphere is NH 3 -N 2 -H 2 , to get hexagonal boron nitride interface coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com