Method for manufacturing light emitting diode (LED) grains

A technology of light-emitting diodes and manufacturing methods, which is applied to electrical components, circuits, semiconductor devices, etc., and can solve problems such as reducing the light-emitting efficiency of light-emitting diode crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

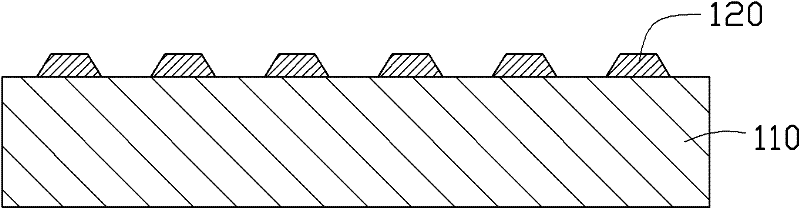

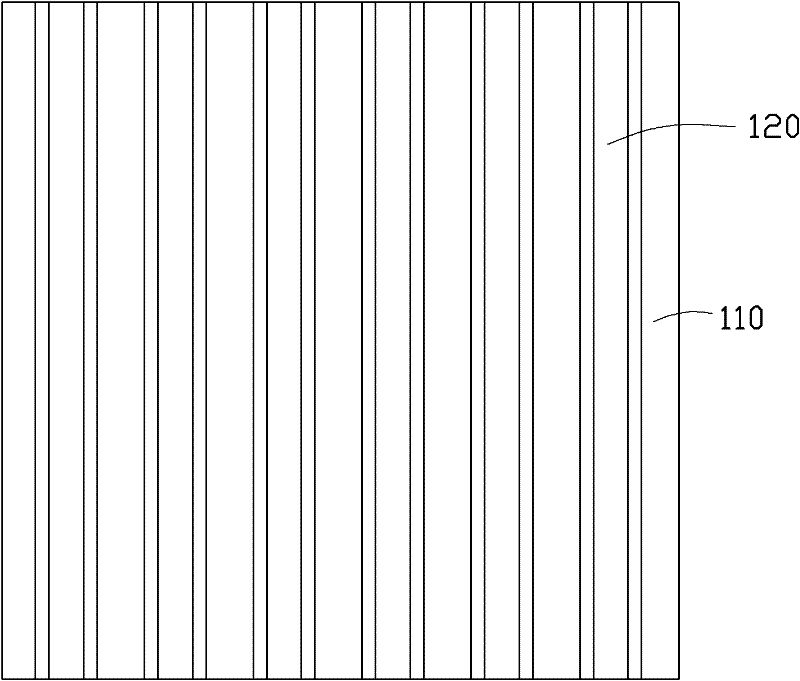

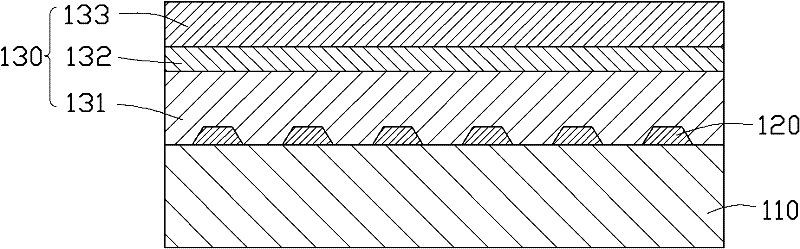

[0039] Such as figure 1 As shown, a sapphire substrate 110 is provided first. Then a silicon dioxide pattern layer 120 is fabricated on the sapphire substrate 110 . See figure 2 , the silicon dioxide pattern layer 120 is composed of a plurality of strip-shaped silicon dioxide patterns arranged in parallel. Such as image 3 As shown, the cross-sectional shape of the elongated silicon dioxide pattern perpendicular to its extending direction is trapezoidal. According to requirements, the cross-sectional shape of the elongated silicon dioxide pattern along the direction perpendicular to its extension can also be a semicircle.

[0040] Such as image 3 As shown, the semiconductor light emitting structure 130 is grown on the surface of the sapphire substrate 110 with the silicon dioxide pattern layer 120 by Metal Organic Chemical Vapor Deposition (MOCVD) or Molecular Beam Epitaxy (MBE). The semiconductor light emitting structure 130 includes an n-type GaN layer 131 , a multi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com