Layer-by-layer analysis method for surface layer of copper alloy material

An analysis method and technology for copper alloys, applied in the field of layer-by-layer analysis of the surface of alloy materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

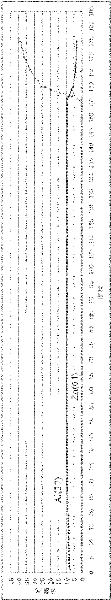

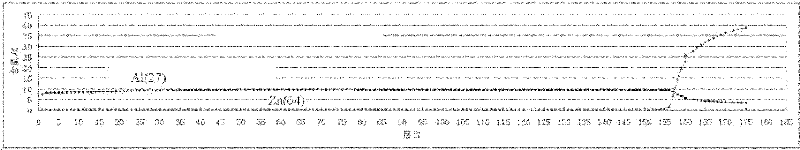

[0036] The method of layer-by-layer analysis on the surface of copper alloy materials by glow discharge mass spectrometry includes the following steps:

[0037] (1) Prepare samples for analysis

[0038] Grind an unknown commercially available brass substrate to 9. It is further polished to a mirror surface, and a thin aluminum bronze film is grown on the substrate surface by radio frequency sputtering deposition; first, the thickness of the aluminum bronze film is calibrated by scanning electron microscope analysis technology, and its thickness is 5.0 μm;

[0039] (2) Select the analysis conditions of the instrument

[0040] Glow discharge ion source conditions: the sampling distance is 12mm, the sample sputtering spot diameter is φ5mm, the ion source argon pressure is 800Pa, and the discharge voltage is DC 800V;

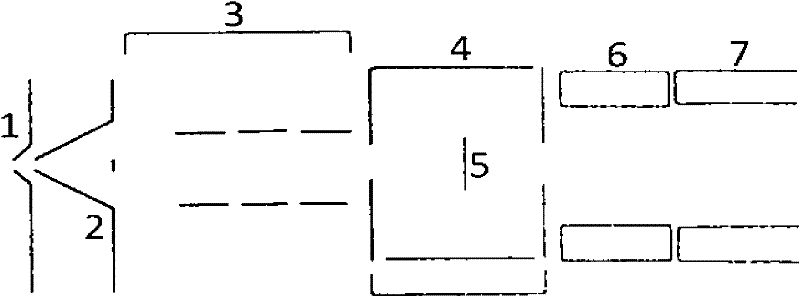

[0041] Glow discharge ion source mass spectrometry interface conditions: the aperture of the ion outlet cone 1 is φ6mm, the aperture of the intercepting cone 2 is φ0.89mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com