Preparation method of reduction state graphene and platinum nanometer particle composite material modified molecularly imprinted membrane electrochemical sensor

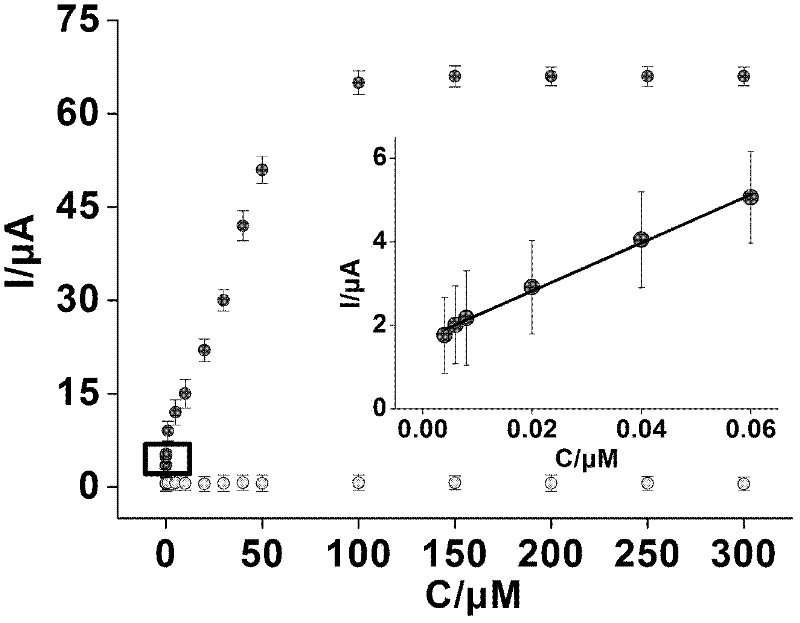

A molecular imprinting and membrane electrochemistry technology, applied in the field of analysis and detection, can solve problems such as affecting the sensitivity of electrochemical sensors, and achieve the effects of increasing sensitivity, catalysis and high and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

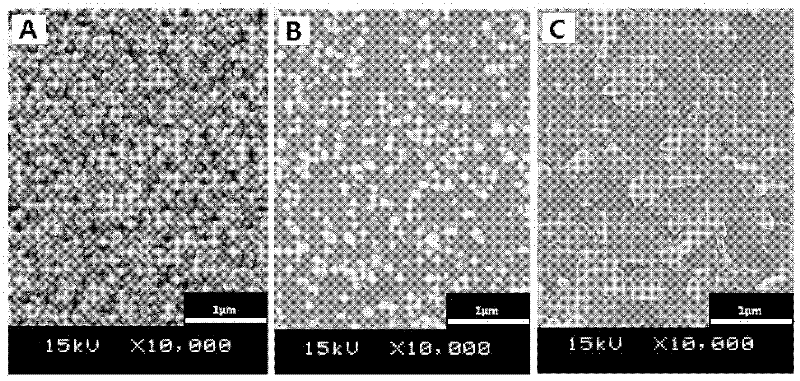

[0040] The preparation method of reduced graphene: take 3.0 g of graphite, add 120 ml of concentrated sulfuric acid, stir in an ice bath, and add a total of 16.0 g of potassium permanganate in three times. The reaction temperature was controlled to 35-40°C and stirred for 20 hours. After stirring, 250 ml of water was added in batches, heated in a water bath and stirred, and the temperature was controlled to 80° C., and the reaction was carried out for 2 hours, and the reactant gradually turned bright yellow. After cooling, 40 ml of hydrogen peroxide was added and stirred overnight to obtain oxidized graphene (GO). It was then washed with acid and water until pH was close to 6. Sonicate the GO for 1-2 hours. 60 mg of GO was added to 600 mg of sodium polystyrene sulfonate (PSS) for 30 min, and the mixture was stirred at 50 °C for 24 h. After cooling, 4 ml of ammonia water and 4 ml of hydrazine hydrate were added, and the mixture was kept at 95-100 °C and stirred for 24 h. Af...

Embodiment 1

[0043] a) Electrode pretreatment: glassy carbon electrode (Φ=3mm) was treated with 0.05μm Al 2 O 3 After polishing the suspension, put it in Piranha solution (30% H 2 O 2 : Concentrated H 2 SO 4 =3:7, V / V) for 2min, then ultrasonically cleaned with absolute ethanol and deionized water for 2min respectively;

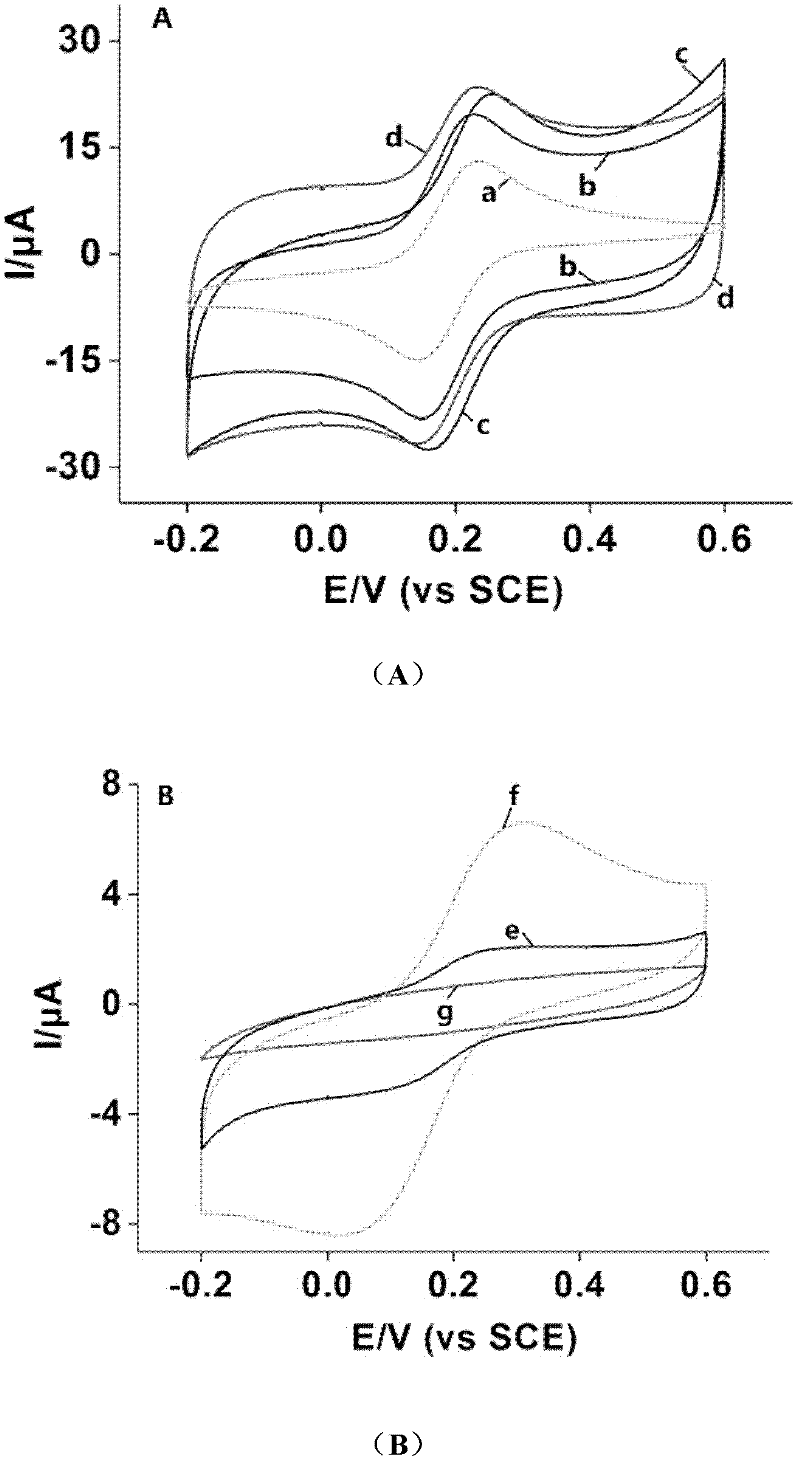

[0044] b) Electrochemical deposition of platinum nanoparticles: The cleaned glassy carbon electrode was placed in a solution containing 0.5 mol·L -1 Sulfuric acid and 5mmol·L -1 In the mixed aqueous solution of hexachloroplatinic acid, in the potential range of -0.2 ~ 0.6V, at 30mV·s -1 The scan rate was cyclically scanned for 3 min; then rinsed with absolute ethanol and deionized water in turn, dried with nitrogen, and then soaked in Piranha solution for 2 min, rinsed with deionized water, and dried with nitrogen to obtain platinum nanoparticles modified electrode;

[0045] c) Assembly of reduced graphene and platinum nanoparticles: 5 μL of 0.5 mg / mL reduced grap...

Embodiment 2

[0049] a) Electrode pretreatment: glassy carbon electrode (Φ=3mm) was treated with 0.05μm Al 2 O 3 After polishing the suspension, put it in Piranha solution (30% H 2 O 2 : Concentrated H 2 SO 4 =3:7, V / V) for 2min, then ultrasonically cleaned with absolute ethanol and deionized water for 2min respectively;

[0050] b) Electrochemical deposition of platinum nanoparticles: The cleaned glassy carbon electrode was placed in a solution containing 0.5 mol·L -1 Sulfuric acid and 5mmol·L -1 In the mixed aqueous solution of hexachloroplatinic acid, in the potential range of -0.2 ~ 0.6V, at 50mV·s -1 The scan rate was cyclically scanned for 10 min; then rinsed with absolute ethanol and deionized water in turn, dried with nitrogen, and then soaked in Piranha solution for 2 min, rinsed with deionized water, and dried with nitrogen to obtain platinum nanoparticles modified electrode;

[0051] c) Assembly of reduced graphene and platinum nanoparticles: 10 μL of 0.5 mg / mL reduced gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com