Method for measuring laser welding temperature field in real time

A real-time measurement and laser welding technology, which is applied in optical radiation measurement, radiation pyrometry, thermometers, etc., can solve the problems of fast welding heat cycle, slow response speed, and high molten pool temperature, so as to improve measurement accuracy and overcome Slow response speed, satisfying the effect of real-time temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] 1. Preparation before welding:

[0027] (1) Fixing of welding processing materials

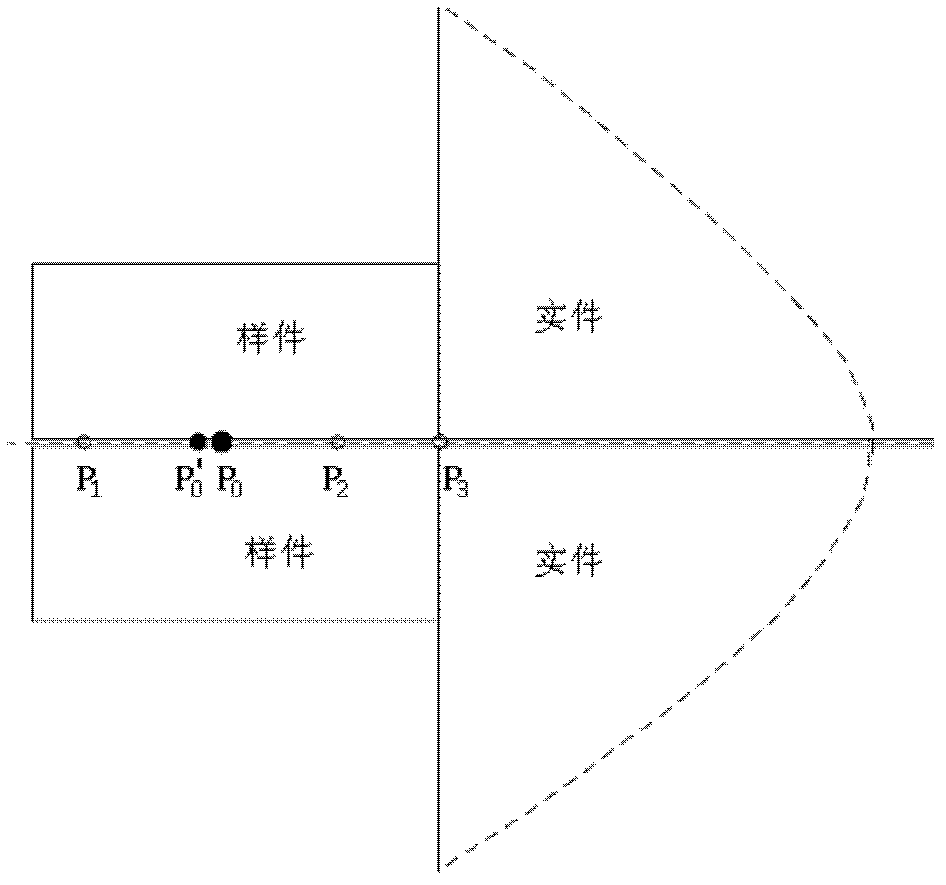

[0028] Install and fix the welding object according to the specified requirements, and then place the welding sample on the front end of the object according to the same requirements, such as figure 1 Show.

[0029] (2) Selection of thermocouple

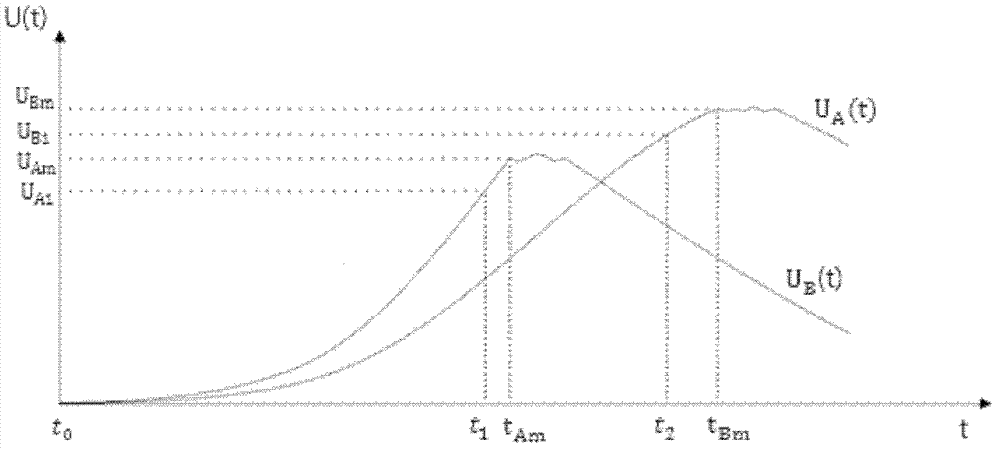

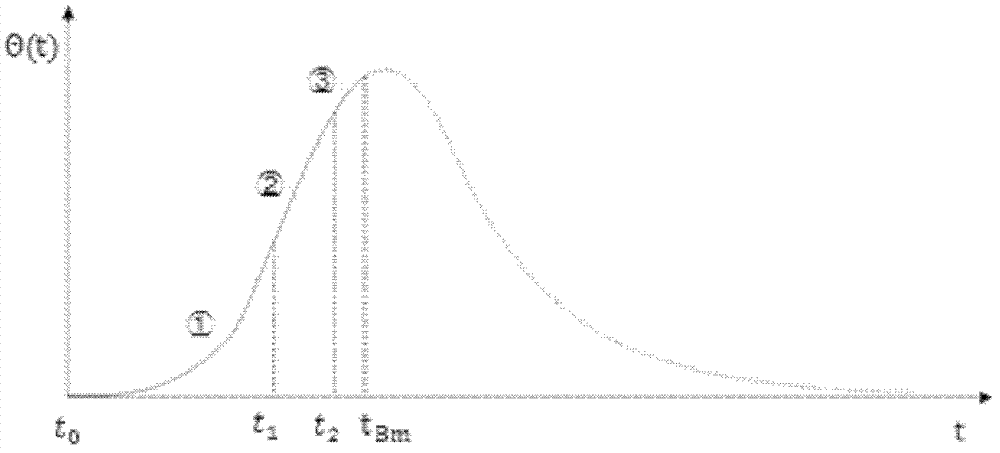

[0030] For thermocouples of the same material, the larger the diameter, the higher the upper limit of the working temperature, but the greater its influence on the temperature field to be measured, the lower the accuracy of the measurement results. Therefore, in actual measurement, the smaller diameter should be selected as much as possible. even silk. The present invention selects two thermocouples with the same material but different diameters, assuming that the diameter of thermocouple A’s wire is Ф A , the nominal maximum operating temperature is T A , the time constant is τ A ; The wire diameter of thermocouple B is Ф B , the nomin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com