Bushing bearing

A bushing bearing, axial technology, used in bearings, bearing components, shafts and bearings, etc., can solve the problems of large surface contact force, increased friction coefficient, damage to the friction surface, etc. side effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

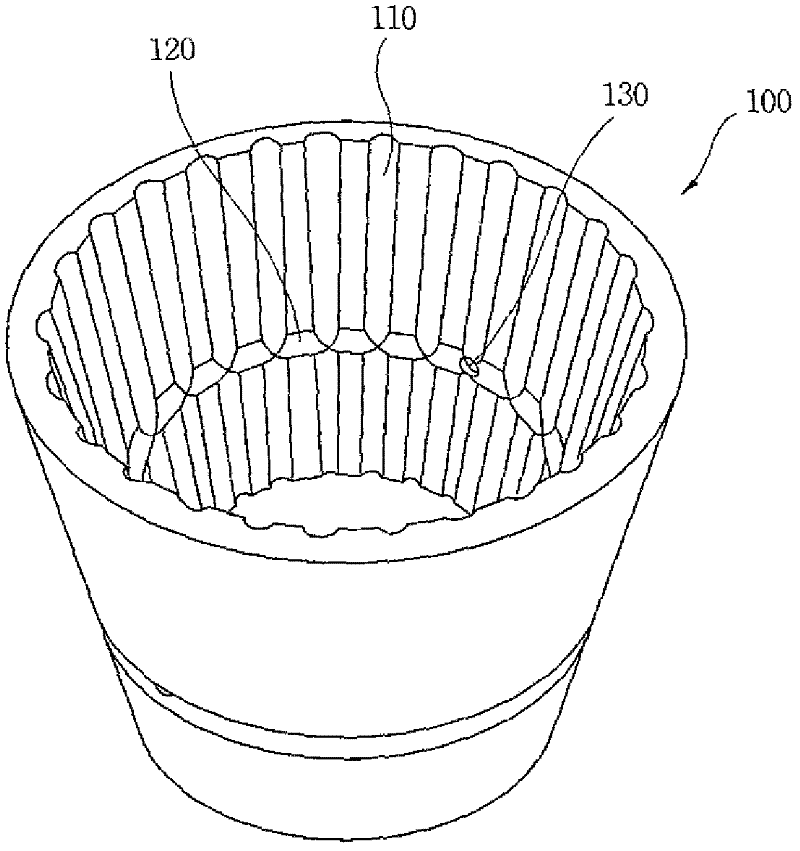

[0033] image 3 It is a diagram of the bush bearing of the first embodiment of the present invention. The bush bearing has a main body (100), and a plurality of oil grooves (110) are formed on the inner peripheral surface of the main body (100) along a direction parallel to the axial direction of the main body (100). The oil groove (110) can be extended to both ends of the main body (100) to make the foreign matter And harmful substances are discharged together with the oil. But aiming at the lubricating effect of moving smoothly, under the environment that appears more important than the discharge of harmful substances, in order to prevent, you can block the two ends of the oil groove (110), which is shorter than the main body (100), so as to prevent oil from flowing from the two ends of the oil groove (100). exhausted at the end.

[0034] The main body (100) contains an oil inflow groove (120) and an oil distribution groove (130). The oil inflow groove (100) penetrates f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com