Preloaded radial permanent magnet bearing

A permanent magnetic bearing and preload technology, which is applied in the direction of bearings, shafts, bearings, mechanical equipment, etc., can solve the problems of low rigidity and inconvenient installation of permanent magnetic suspension bearings, and achieve the effects of high rigidity, reduced inconvenience, and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

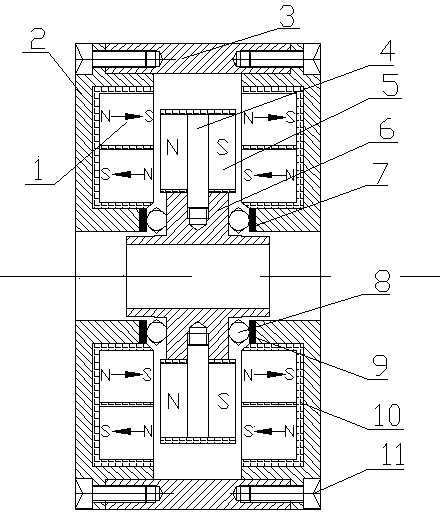

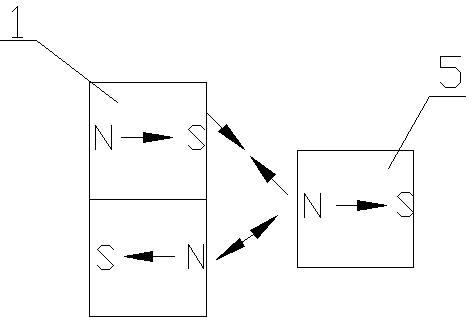

[0033] Embodiment one: see figure 1 , the preloaded radial permanent magnet bearing includes an outer ring (3), an inner ring (6), two side rings (2), two static permanent magnet ring sets (1) and a moving permanent magnet ring set ( 5), characterized in that: the two side rings (2) are respectively fixed on both sides of the outer ring (3) by hexagon socket head cap screws (11); the two static permanent magnetic ring groups (1) are respectively embedded in In the annular grooves of the two side rings (2); the dynamic permanent magnet ring group (5) is fixed on the inner ring (6) through the set screw (4) and is in the two static permanent magnet ring groups (1 ); each static permanent magnet ring group (1) consists of two large semicircular permanent magnet rings A, B and two small semicircular permanent magnet rings C, D. Two nested circular permanent magnet rings, the eight large and small semicircular permanent magnet rings A, B, C, and D are all axially magnetized, and ...

Embodiment 2

[0034] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows: when the above-mentioned permanent magnet bearing is used in industry, each permanent magnet ring and two side rings (2) and outer ring (3) (see Figure 8 ) and the inner ring (6) are embedded with a magnetically permeable sheet (10), and the magnetically permeable sheet (10) is composed of a material with high magnetic permeability (such as soft iron, silicon steel sheet, etc.), so that the dynamic and static permanent magnet rings The distribution of the magnetic field lines is regular, the magnetic force of the permanent magnetic ring increases under the same volume, and the magnetic shielding of the entire permanent magnetic levitation bearing is also realized, which reduces the influence of the outside world on the internal magnetic field and increases the stability of the magnetic field.

[0035] Ceramic ball bearings (9) are installed between the two side ...

Embodiment 3

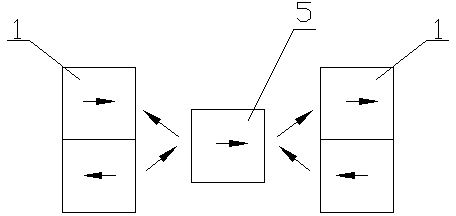

[0041] Embodiment three: see Figure 8 , this embodiment is basically the same as Embodiment 1, and the special feature is: the moving permanent magnet ring group (5) is composed of two permanent magnet rings with the same size and the same axial magnetization direction, and the two permanent magnet rings Between them, there is another static permanent magnet ring group (1) fixedly connected to the inner middle part of the outer ring (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com