Containerized-type energy-saving low-noise water-cooling centrifugal pump

A cartridge-type, low-noise technology, applied in the field of water pumps, can solve the problems of easily damaged bearings and mechanical seals, low coaxiality, vibration, etc., and achieve the effects of high allowable temperature rise, improved coaxiality, and reduced noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

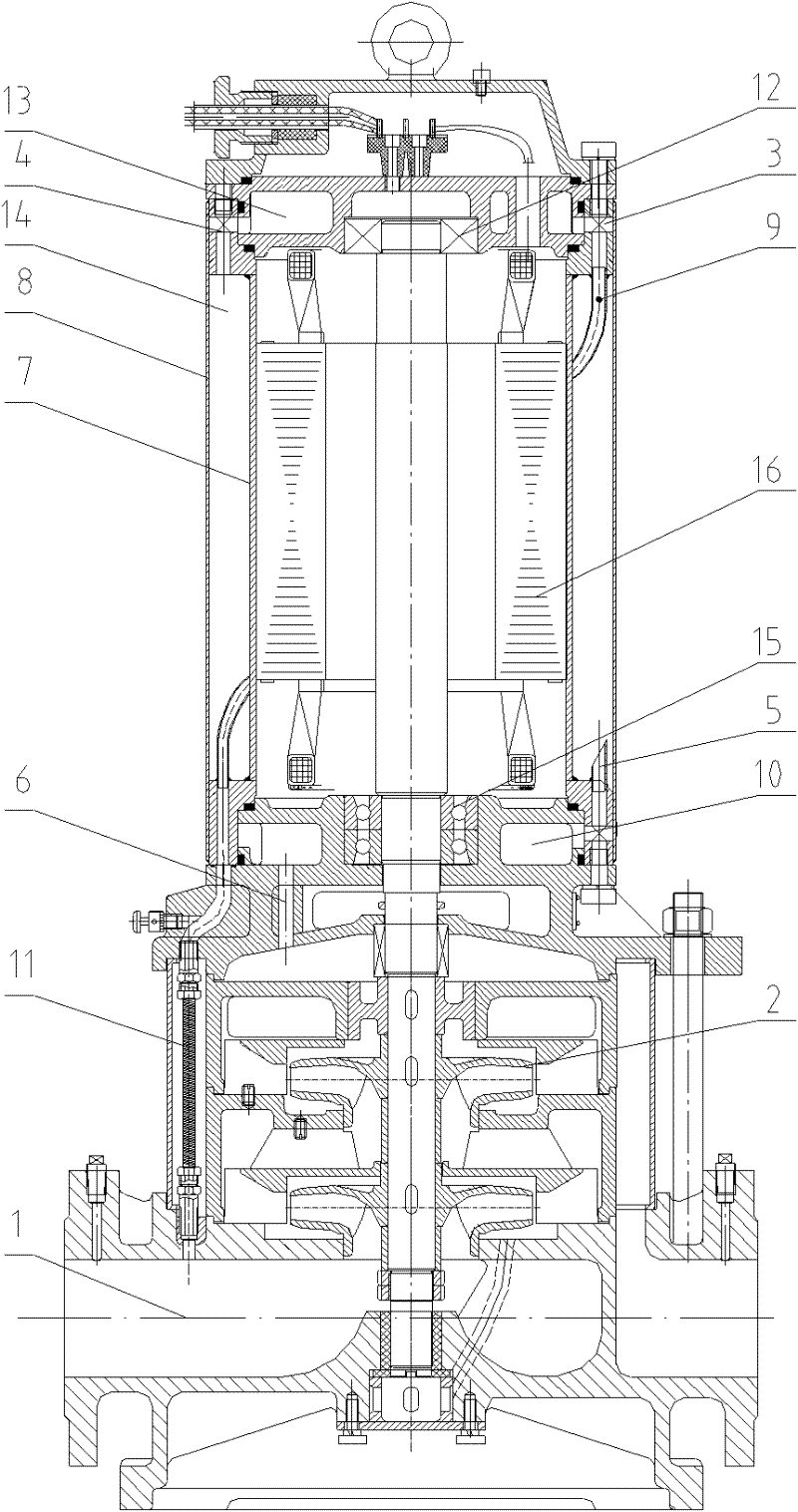

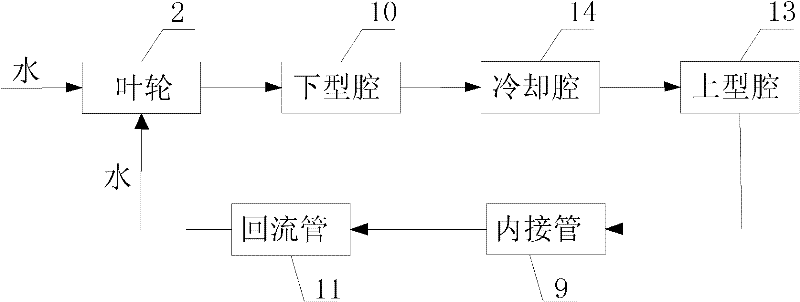

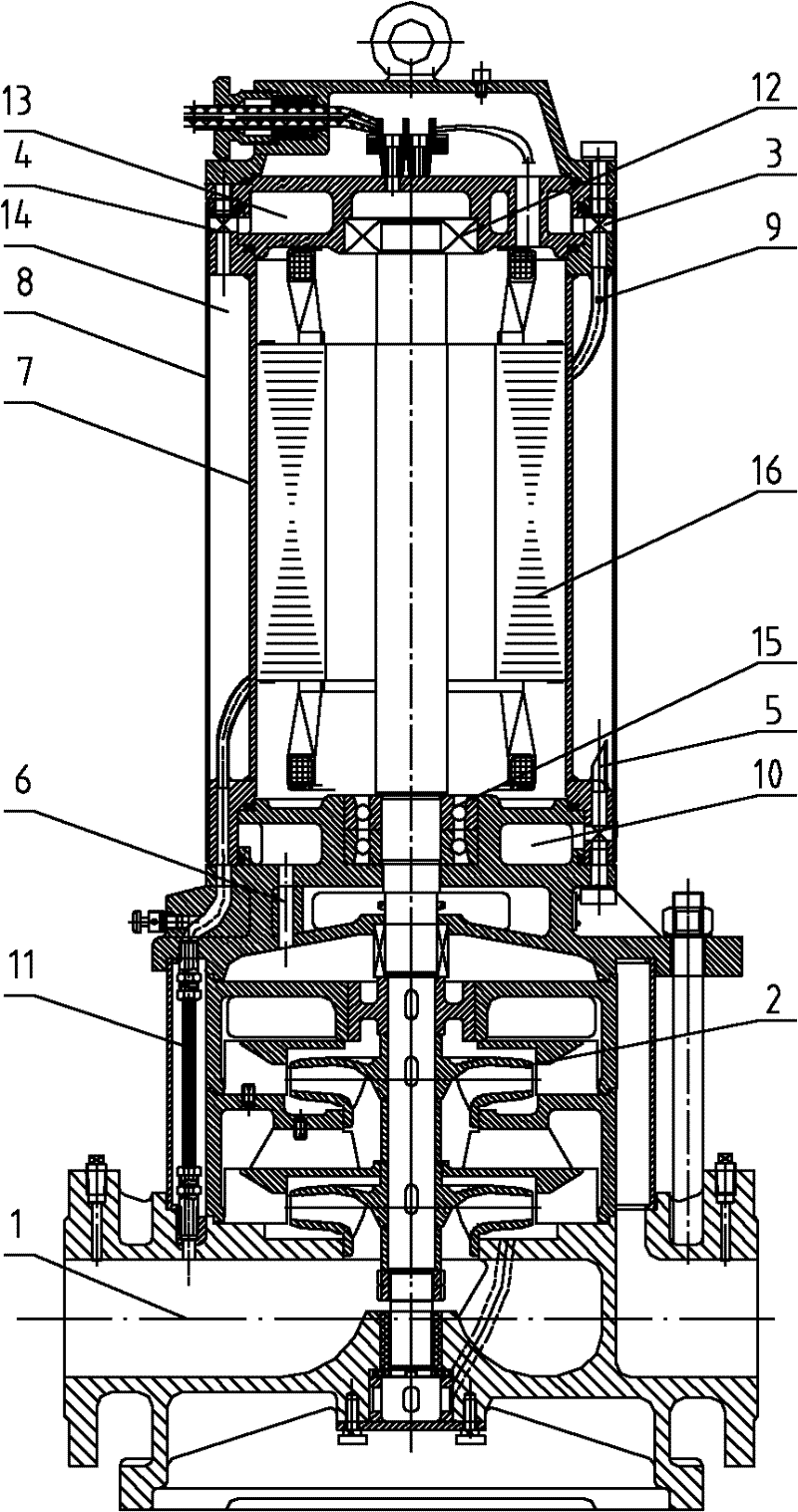

[0037] See figure 1 , The containerized energy-saving low-noise water-cooled centrifugal pump includes a pump body and a motor that provides power within the pump body. The pump body includes an outer cylinder 8, a connected upper bearing 12 and a lower bearing 15, and a motor fixed in the outer cylinder 8. The rotor part 16, the upper cavity 13, the lower cavity 10, the cooling cavity 14 and the impeller 5 at the bottom of the pump.

[0038] The upper bearing 12 is the motor shaft and is coaxial with the lower bearing 15. The previous coupling structure is removed and the coaxiality between the pump and the motor is improved. The upper bearing 12 and the lower bearing 15 are both located in the middle of the outer cylinder 8 and are the main part of the pump. Among them, a motor stator and rotor component 16 is provided on the periphery of the upper bearing 12.

[0039] The cavity between the outer cylinder 8 and the motor housing 7 constitutes a cooling cavity 14. The cooling ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com