Waste heat power generation method of Stirling engine

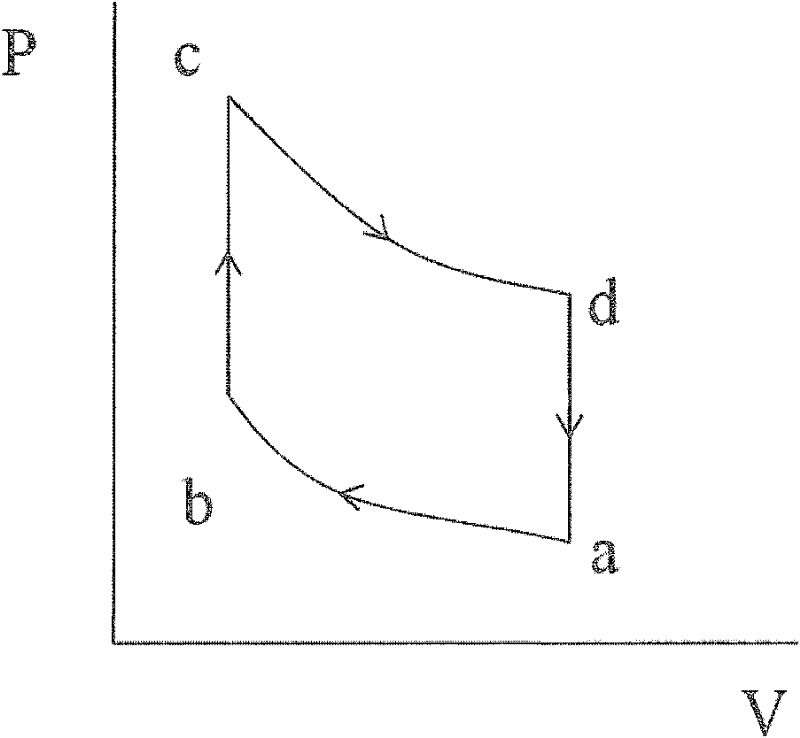

A Stirling engine and waste heat power generation technology, which is applied in the direction of machines/engines, hot gas variable capacity engine devices, mechanical equipment, etc., can solve the problems of unsuitable utilization of scattered waste heat sources, high temperature of waste heat sources, and low power quality. Achieve the effect of improving energy utilization rate, small overall investment, and high heat-power conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

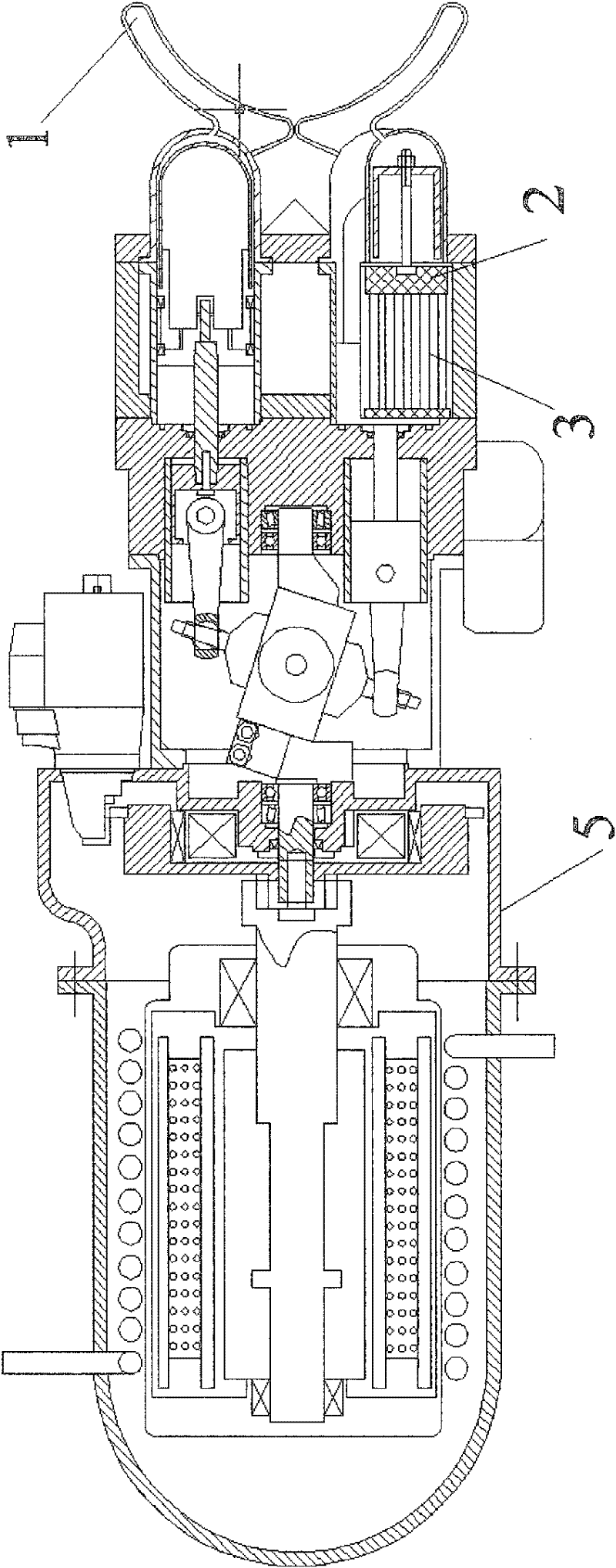

[0023] Embodiment 1: The heat absorber 1 of the Stirling engine 4 is placed in the flue of a power plant boiler or an industrial boiler, and the heat absorber 1 is placed near the front end of the heat collecting tube 7 without affecting the operation and performance of the boiler , heat-collecting pipe 7 is wrapped with thermal insulation material 6, and Stirling engine 4 except heat absorber 1, regenerator 2, cooler 3 and other components and generator 5 are fixed on the outside of the flue. According to the boiler flue gas temperature and thermal power, multiple heat absorbers 1 of Stirling engines 4 can be arranged in the flue to realize the comprehensive utilization of flue gas at different temperature steps.

Embodiment 2

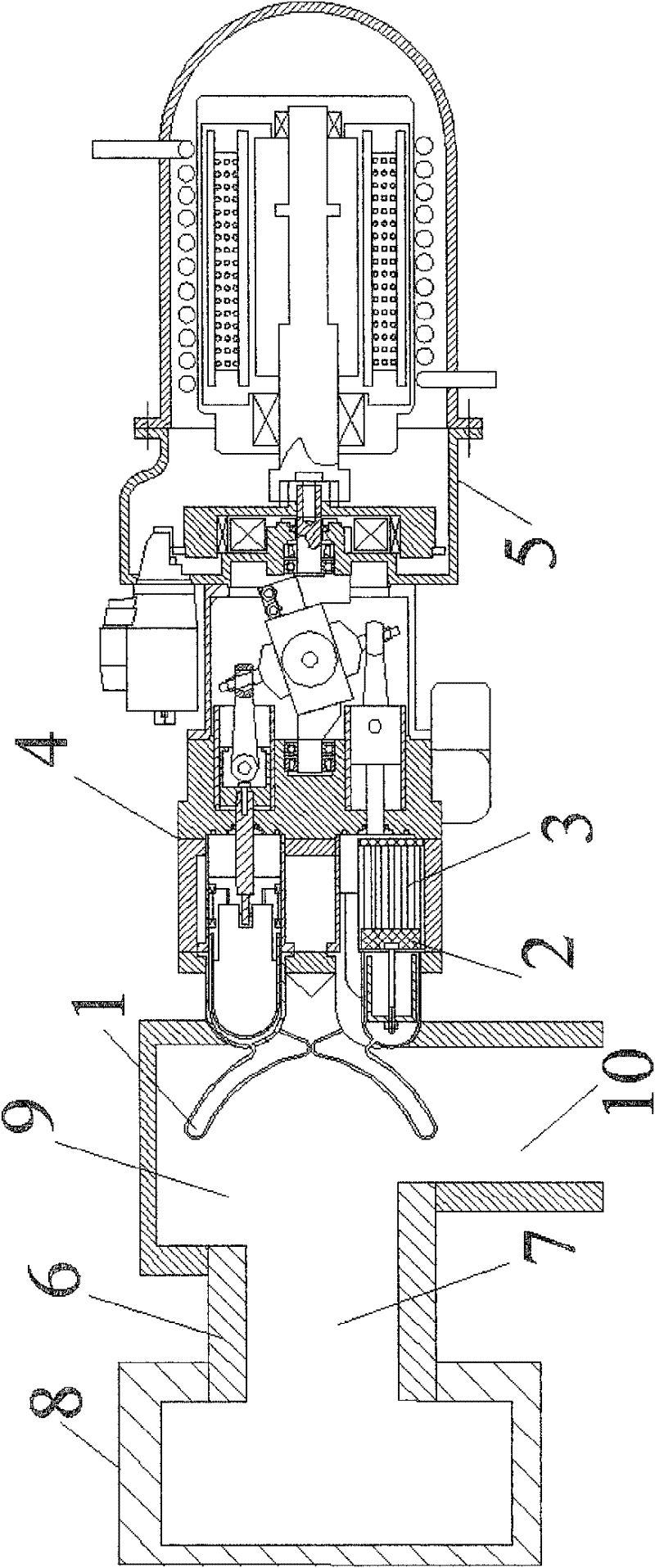

[0024] Embodiment 2: The steam discharged from the final stage blades when the steam turbine is working is used as the heat source 8, and the heat collecting pipe 7 wrapped with the heat insulating material 6 is led to the heat absorber 1 of the Stirling engine 4, in order to strengthen the steam and heat absorber 1 heat exchange effect, the heat absorber 1 of the Stirling engine 4 is arranged in a gas collecting chamber 9 connected with the heat collecting pipe 7, and the steam heats the inner work of the heat absorber 1 of the Stirling engine 4 in the gas collecting chamber 9 quality, pushing the Stirling engine 4 to work. In order to prevent water vapor from condensing in the gas collecting chamber 9 and causing corrosion on the surface of the heat absorber 1, the heat absorber 1 of the Stirling engine 4 is designed to extend from the top of the gas collecting chamber 9, and to be formed with the wall of the gas collecting chamber 9. Sealing, the regenerator 2 of the Stirli...

Embodiment 3

[0025] Embodiment 3: With the exhaust gas of the internal combustion engine as the heat source 8, the heat absorber 1 of the Stirling engine 4 extends from the top of the gas collection chamber 9 and is placed in the middle of the gas collection chamber 9, and the exhaust gas of the internal combustion engine is equipped with heat insulating material 6 from the outside The heat collecting pipe 7 leads to the gas collecting chamber 9, heats the heat absorber 1 of the Stirling engine 4, and promotes the work of the Stirling engine 4. On the outside of the road, the Stirling engine 4 drives the generator 5 to generate electricity through a coupling. The flue gas of the internal combustion engine after heat exchange is discharged through the exhaust pipe 10 connected with the gas collection chamber 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com