Cylindrical composite material bridge anti-collision device

A composite material and anti-collision device technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of difficult repair, poor anti-collision effect and high cost, and achieve fast and convenient installation, convenient replacement and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

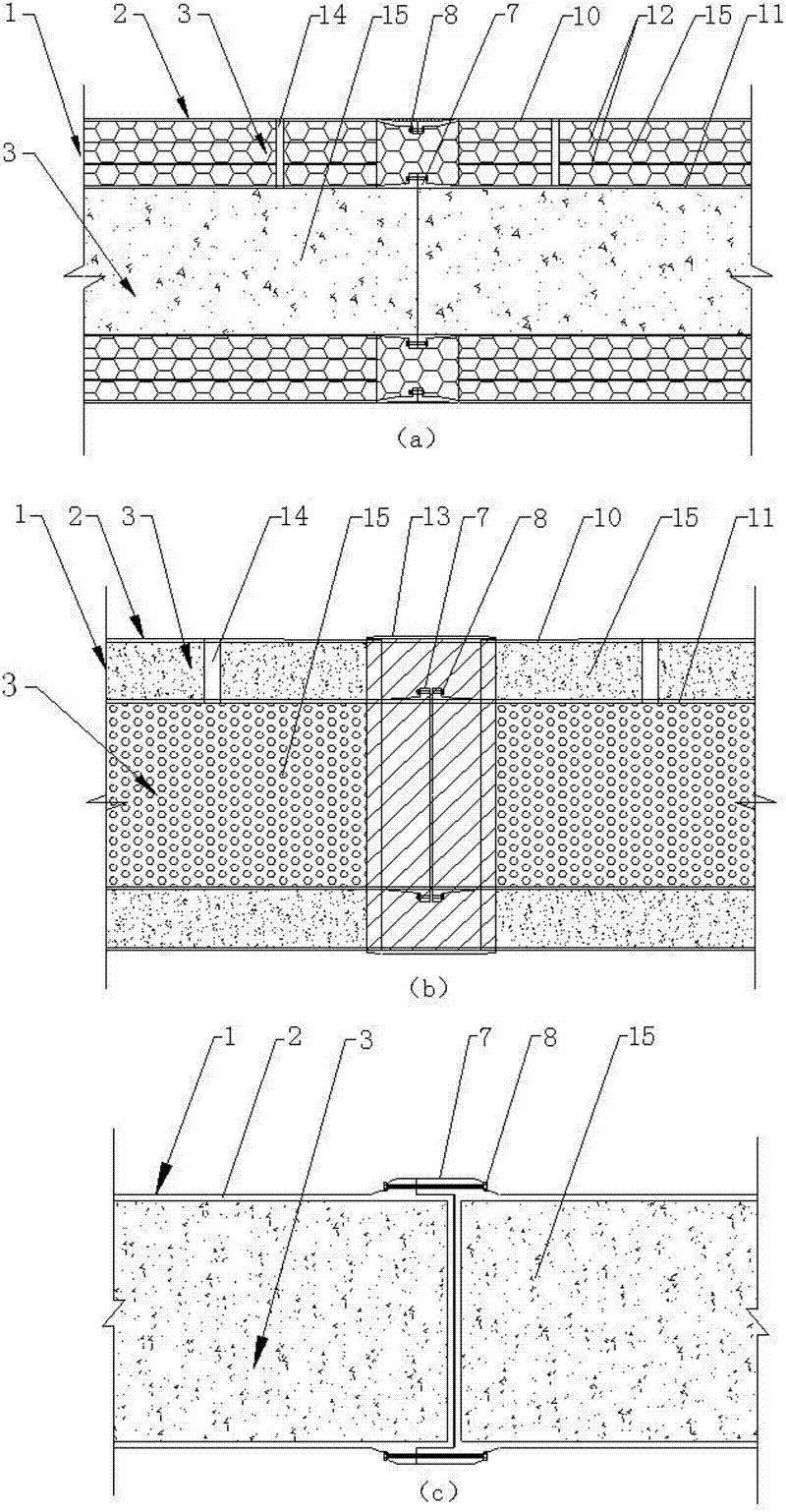

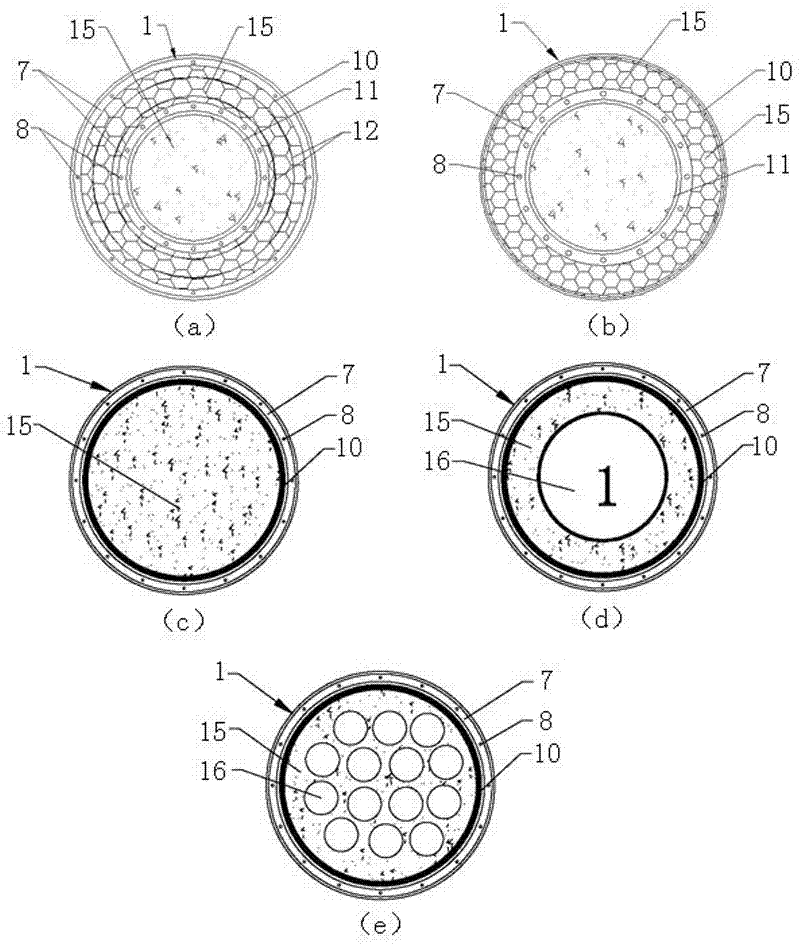

[0033] The tubular composite material bridge anti-collision device of the present invention, as figure 1 (a) shown. The cylinder 2 of the anti-collision unit 1 is composed of an outer cylinder 10, an inner cylinder 11 and two layers of intermediate cylinders 12. Each part of the cylinder 2 is made of glass fiber and unsaturated polyester resin. The impact member 4 is prepared by winding process, and the curved cylindrical anti-collision member 5 is prepared by hand lay-up process; polyurethane foam is poured between the outer cylinder 10 and the inner cylinder 11 as a buffer energy-dissipating material 15 between the two, so that the cylinder 2 are bonded as a whole; after the anti-collision device is installed around the pier, ceramsite is filled into the inner cylinder 11 through the filling hole 7 as a buffer energy-dissipating material 15; bolts 8 are used to connect the inner cylinder 11 outside The flange 7 and the flange 7 on the inside of the outer cylinder 10 are bon...

Embodiment 2

[0035] The tubular composite material bridge anti-collision device of the present invention, as figure 1 (b) shown. The cylinder body 2 of the anti-collision unit 1 is composed of an outer cylinder body 10 and an inner cylinder body 11. Each part of the cylinder body 2 is made of glass fiber and vinyl resin. The cylindrical anti-collision member 5 is prepared by cutting and assembling the straight cylindrical anti-collision member 4 according to the angle and then through the hand lay-up process; between the outer cylinder 10 and the inner cylinder 11, coal gangue powder mixed with polyurethane foam material is poured as a buffer energy-dissipating material 15; the inner cylinder 3 is pre-filled with a mixture of sand and ceramsite as a buffer energy-dissipating material 15; bolts 8 are used to connect the flange 7 on the outer side of the inner cylinder 11, and an annular ferrule is set at the joint of the outer cylinder 10 13. Paste the contact between both sides of the fer...

Embodiment 3

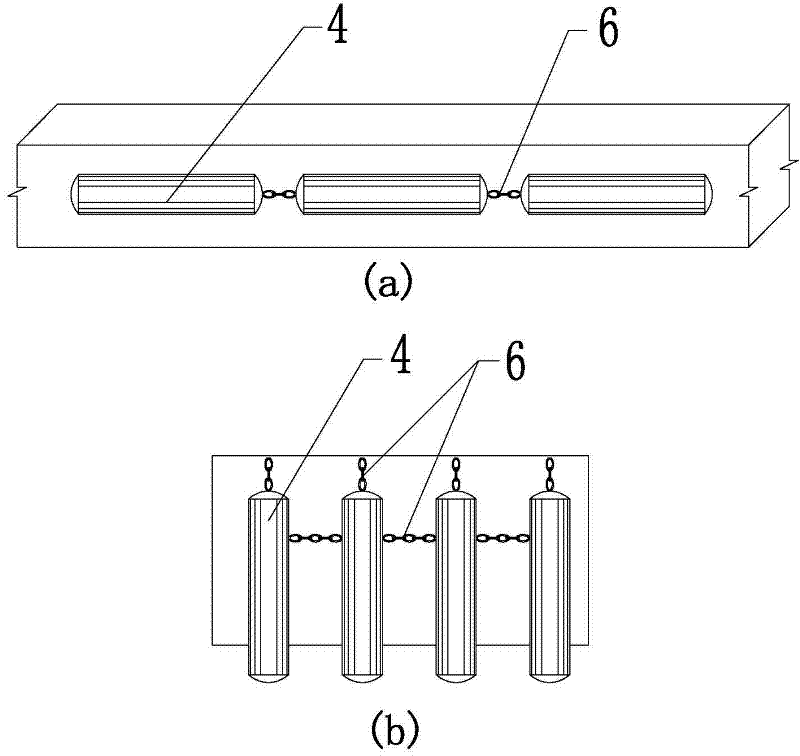

[0037] The tubular composite material bridge anti-collision device of the present invention, as Figure 4 (a) shown. The cylinder 2 of the single-layer straight cylindrical anti-collision member 4 is made of basalt fiber cloth and vinyl ester resin through a winding process to form a composite material tube. The hollow ball is used as a hollow device 16, and recycled rubber particles are tightly filled between the outer cylinder body 10 and the hollow device 16 as a buffer energy-dissipating material 15, and then several straight cylindrical anti-collision members 4 made of composite materials are connected in series through connecting rods 6 to form a horizontal Anti-collision body, especially suitable for dock anti-collision needs, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com