Titanium dioxide nanocomposite and one-step preparation method by utilizing anodic oxidation device

A nanocomposite material, titanium dioxide technology, applied in the field of electrode materials and its preparation, can solve the problems of low nanotube length and inability to fully meet the length requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

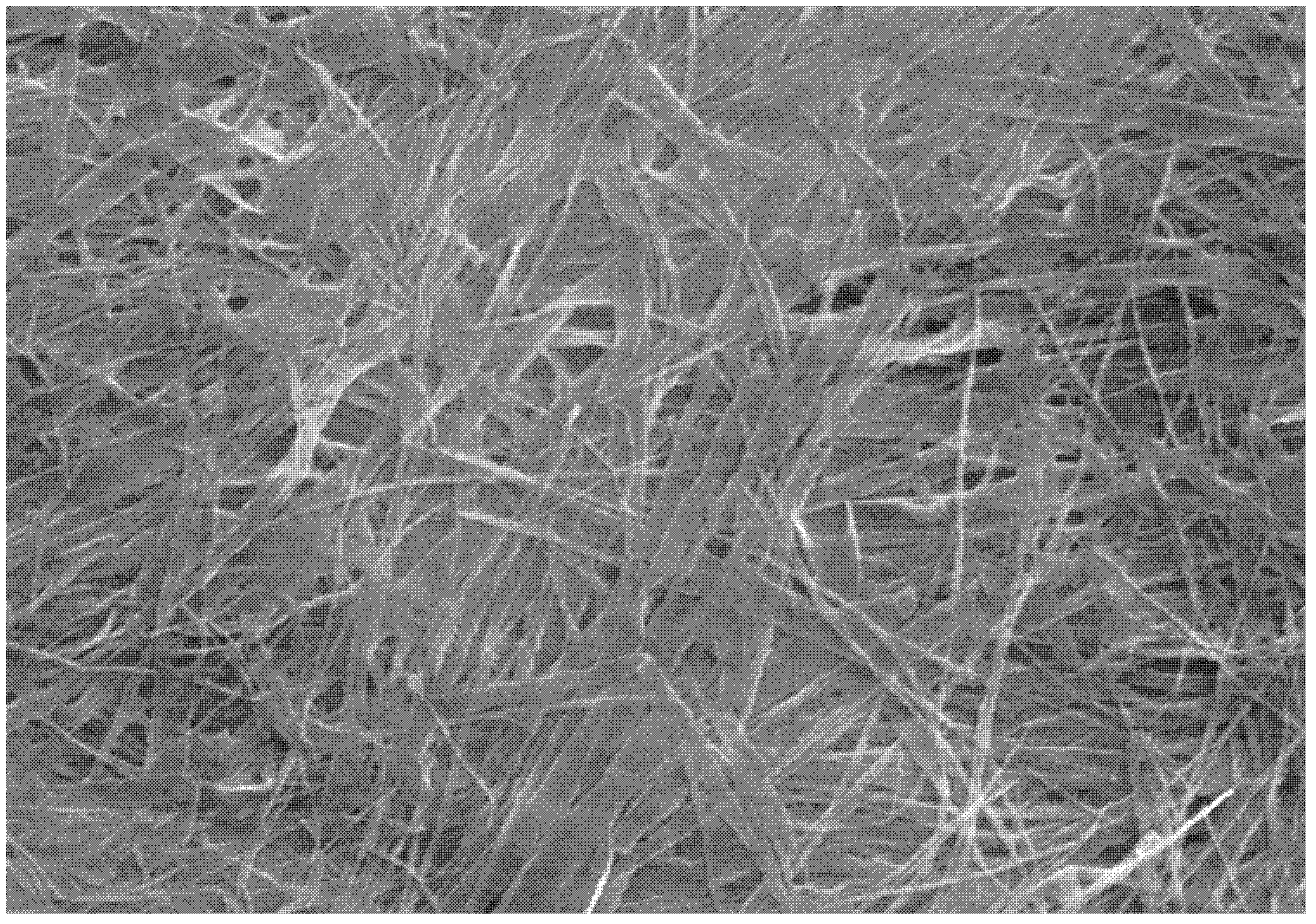

Image

Examples

Embodiment 1

[0019] The anodic oxidation method uses a constant voltage power supply instrument and uses a two-electrode system (the anode is a pure titanium sheet and the cathode is a platinum sheet) in NH 4 A method for preparing nanomaterials by reacting in a mixed solution of F-ethylene glycol / water.

[0020] The process parameters used in the formation of anodic oxidation are:

[0022] Anodizing temperature (solution temperature): 20°C

[0023] Anodizing time: 20h

[0024] Electrolyte concentration: NH 4 The concentration of F is 0.3wt%, the volume percentage of water is 2vol%

[0025] Its steps of the preparation method of above-mentioned novel nano-material are as follows:

[0026] (1) Polish the pure titanium sheet with 240#, 400#, 600#, 800#, 1500#, 2000#, 3000# sandpaper in sequence until smooth, then clean it with deionized water, and dry it by ultrasonication with absolute ethanol for 5 minutes.

[0027] (2) Put the pure titanium sheet into...

Embodiment 2

[0030] The anodic oxidation method uses a constant voltage power supply instrument and uses a two-electrode system (the anode is a pure titanium sheet and the cathode is a platinum sheet) in NH 4 A method for preparing nanomaterials by reacting in a mixed solution of F-ethylene glycol / water.

[0031] The process parameters used in the formation of anodic oxidation are:

[0032] Anodizing voltage: 50V

[0033] Anodizing temperature (solution temperature): 30°C

[0034] Anodizing time: 16h

[0035] Electrolyte concentration: NH 4 The concentration of F is 0.2wt%, the volume percentage of water is 5vol%

[0036] Its steps of the preparation method of above-mentioned novel nano-material are as follows:

[0037] (1) Polish the pure titanium sheet with 240#, 400#, 600#, 800#, 1500#, 2000#, 3000# sandpaper in sequence until smooth, then clean it with deionized water, and dry it by ultrasonication with absolute ethanol for 5 minutes.

[0038] (2) Put the pure titanium sheet into...

Embodiment 3

[0041] The anodic oxidation method uses a constant voltage power supply instrument and uses a two-electrode system (the anode is a pure titanium sheet and the cathode is a platinum sheet) in NH 4 A method for preparing nanomaterials by reacting in a mixed solution of F-ethylene glycol / water.

[0042] The process parameters used in the formation of anodic oxidation are:

[0043] Anodizing voltage: 70V

[0044] Anodizing temperature (solution temperature): 60°C

[0045] Anodizing time: 48h

[0046] Electrolyte concentration: NH 4 The concentration of F is 0.1wt%, the volume percentage of water is 3vol%

[0047] Its steps of the preparation method of above-mentioned novel nano-material are as follows:

[0048] (1) Polish the pure titanium sheet with 240#, 400#, 600#, 800#, 1500#, 2000#, 3000# sandpaper in sequence until smooth, then clean it with deionized water, and dry it by ultrasonication with absolute ethanol for 5 minutes.

[0049] (2) Put the pure titanium sheet into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com