Method for preparing mesoporous titanium oxide film loaded on substrate

A mesoporous titanium oxide and substrate technology, applied in the coating process and coating of metal materials, can solve the problems of reduced biocompatibility, easy cracks on the surface, difficult removal of template agents, etc., to increase heat flux Quantity transfer, good biocompatibility, favorable effect of fluid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

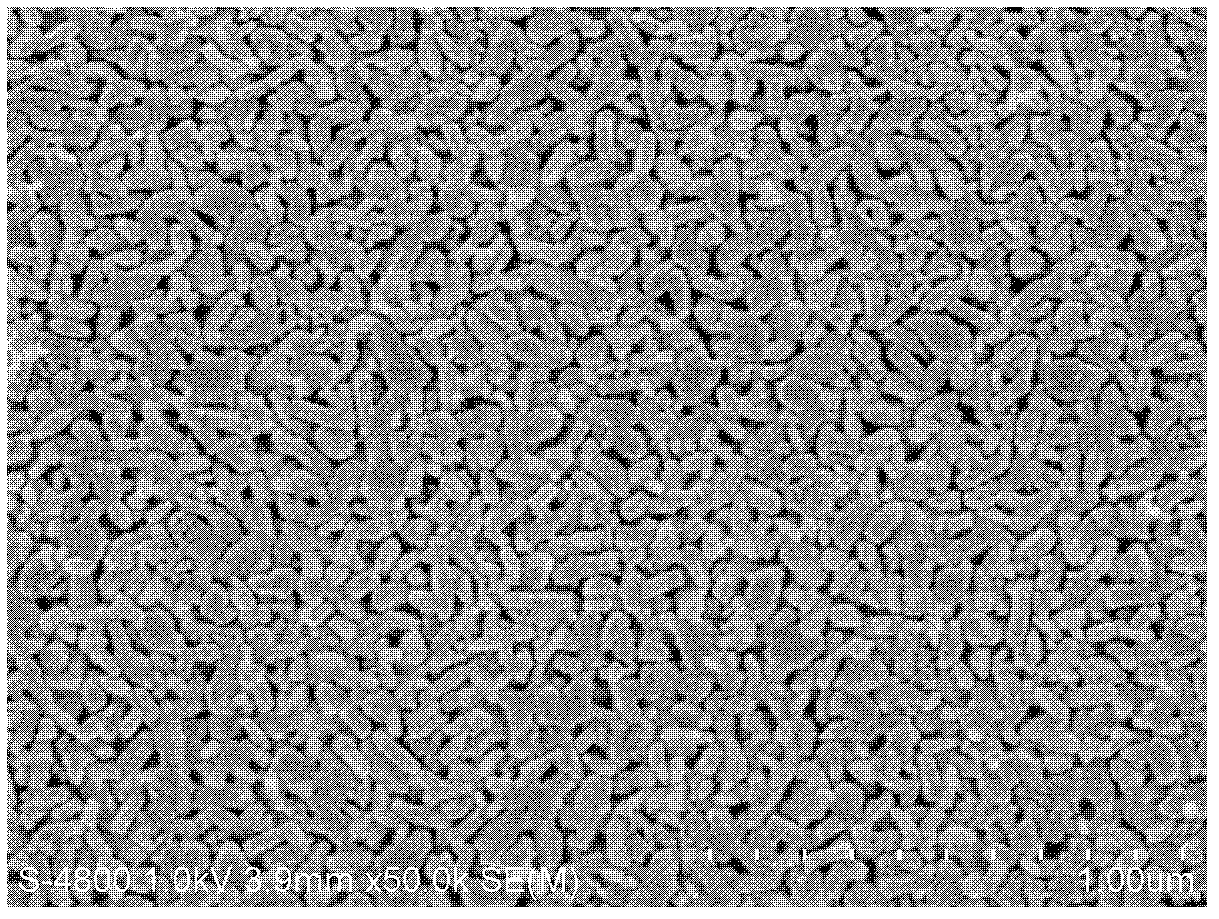

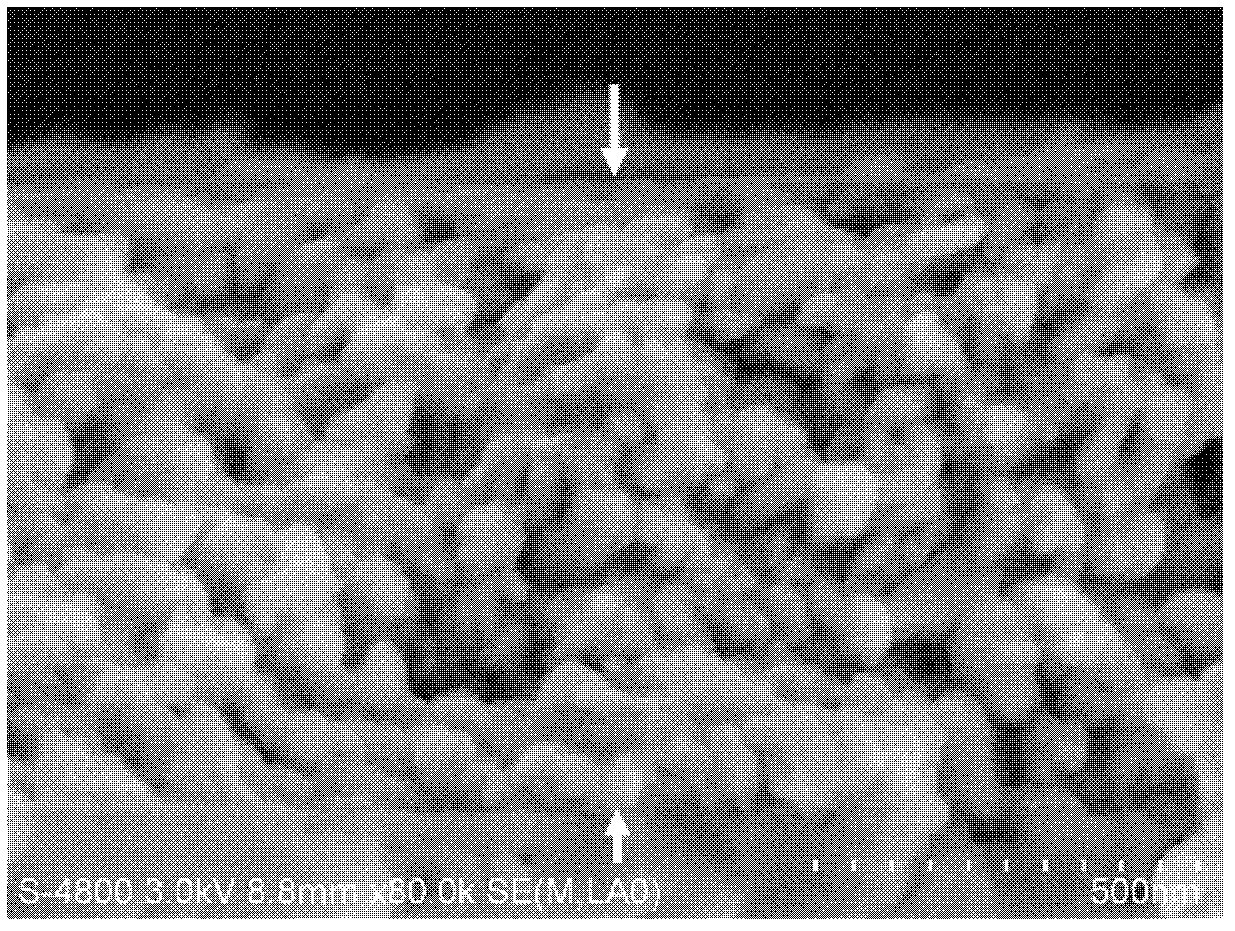

Image

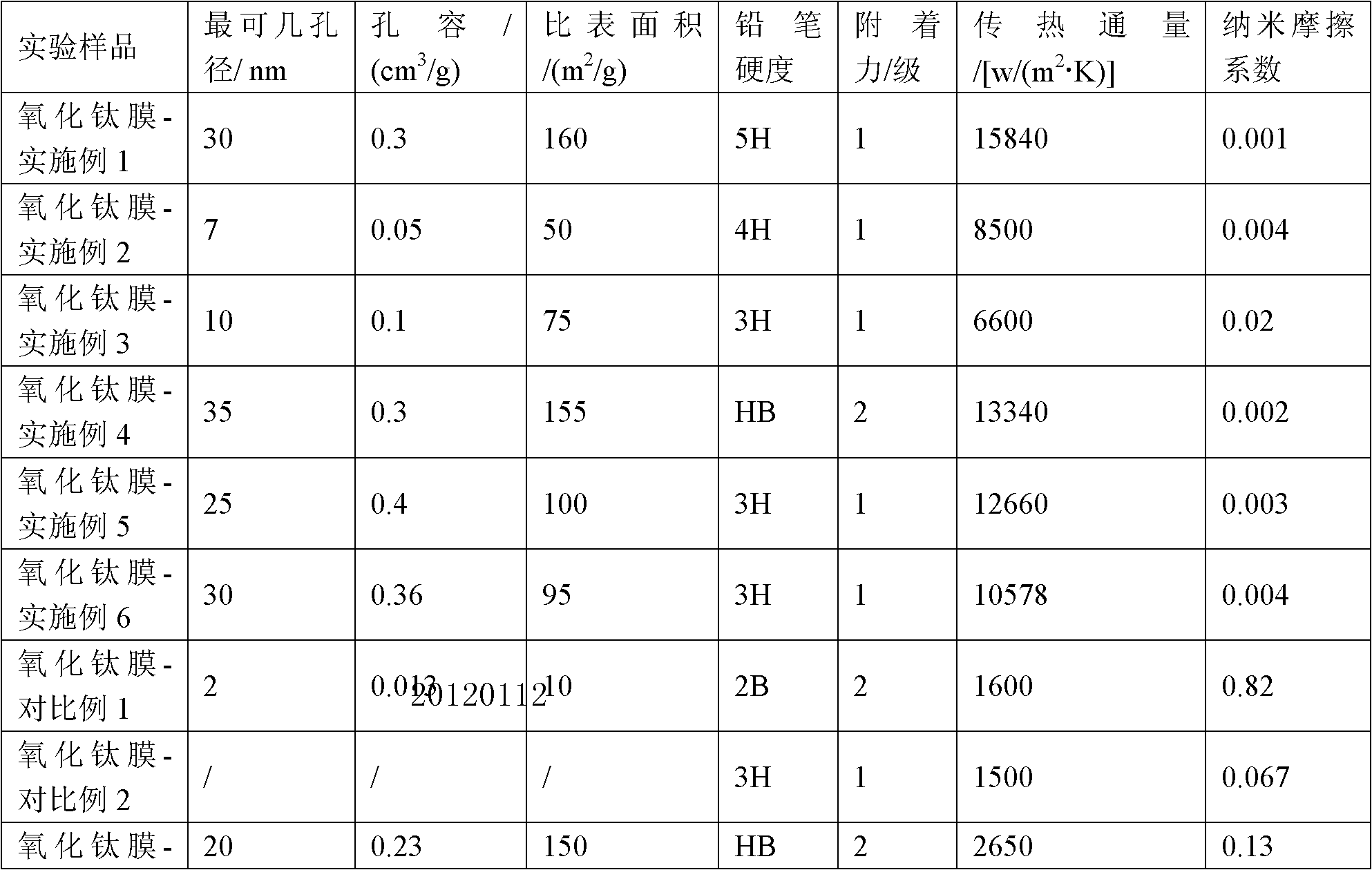

Examples

Example Embodiment

[0026] Example 1:

[0027] ① Measure 14.7mL tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ) was added to the dissolved potassium acetate (CH 3 COOK) in 34.4mL glacial acetic acid (CH 3 COOH) solution in the wide-mouth bottle, the specific ratio according to TiO2 : K 2 CO 3 (mol)=2:1. Measure 2.57mL acetylacetone (CH 3 COCH 2 COCH 3 ), 2.2mL ethylene glycol methyl ether (CH 3 COCH 2 COCH 3 ) was slowly added to the above solution, stirred for 2-3 hours, and left to age for 3 days to obtain a sol [12].

[0028] ② Surface hydroxylation treatment of the titanium substrate: ultrasonic cleaning with deionized water for 15 minutes, then ultrasonic cleaning with ethanol for 15 minutes, then rinsing the substrate with deionized water for 3 times, each time for 5 minutes, and then repeating the ethanol cleaning step 5 times, and then Ultrasonic wash with acetone for 8 minutes, then rinse the substrate with deionized water for 3 times, 5 minutes each time, repeat the acetone cleaning...

Example Embodiment

[0031] Example 2:

[0032] ①Measure 14.7mL tetrabutyl titanate and add it into a jar of 20mL glacial acetic acid solution dissolved in potassium acetate under stirring state, the specific proportion is according to TiO 2 : K 2 CO 3 (mol)=4:1. Measure 2.5mL of acetylacetone and 36mL of ethylene glycol methyl ether into the above solution slowly, stir for 2 to 3 hours, and leave to age for 10 days to obtain a sol.

[0033] ② Immerse the titanium substrate after surface hydroxylation (the surface hydroxylation is carried out as in Example 1) into the above-mentioned sol that has been left to stand and age and pull it up. The product obtained after drying at 150°C for 10 minutes to obtain a polycrystalline form, and then Repeat the pulling process until a thin film with a thickness of 500 nm and regular morphology is obtained.

[0034] ③ The obtained film was baked at 350°C for 8 hours in an air atmosphere, then kept in a hydrothermal kettle at 150°C for 12 hours in a saturate...

Example Embodiment

[0036] Example 3:

[0037] ① Measure 14.7mL tetrabutyl titanate and add it into a jar of 24.4mL glacial acetic acid solution dissolved in potassium acetate under stirring state, the specific proportion is according to TiO 2 : K 2 CO 3 (mol)=6:1. Measure 2.5 mL of acetylacetone and 31.5 mL of ethylene glycol methyl ether into the above solution slowly, stir for 2 to 3 hours, and leave to age for 6 days to obtain a sol.

[0038] ② Immerse the titanium substrate after surface hydroxylation (the surface hydroxylation is carried out as in Example 1) into the above-mentioned sol that has been left to stand and age and pull it up. The product obtained after drying at 300°C for 15 minutes to obtain a polycrystalline form, and then Repeat the pulling process until a thin film with a thickness of 500 nm and regular morphology is obtained.

[0039] ③ The obtained film was baked at 500°C for 8 hours in an air atmosphere, and then kept in a saturated calcium chloride aqueous solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com