Inclined entering gas spray header applied to metal organic chemical vapor deposition reactor

A metal-organic chemistry and gas shower head technology, applied in gaseous chemical plating, metal material coating technology, electrical components, etc., can solve problems such as difficult formation of stable laminar flow, exhaustion of reactants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 109

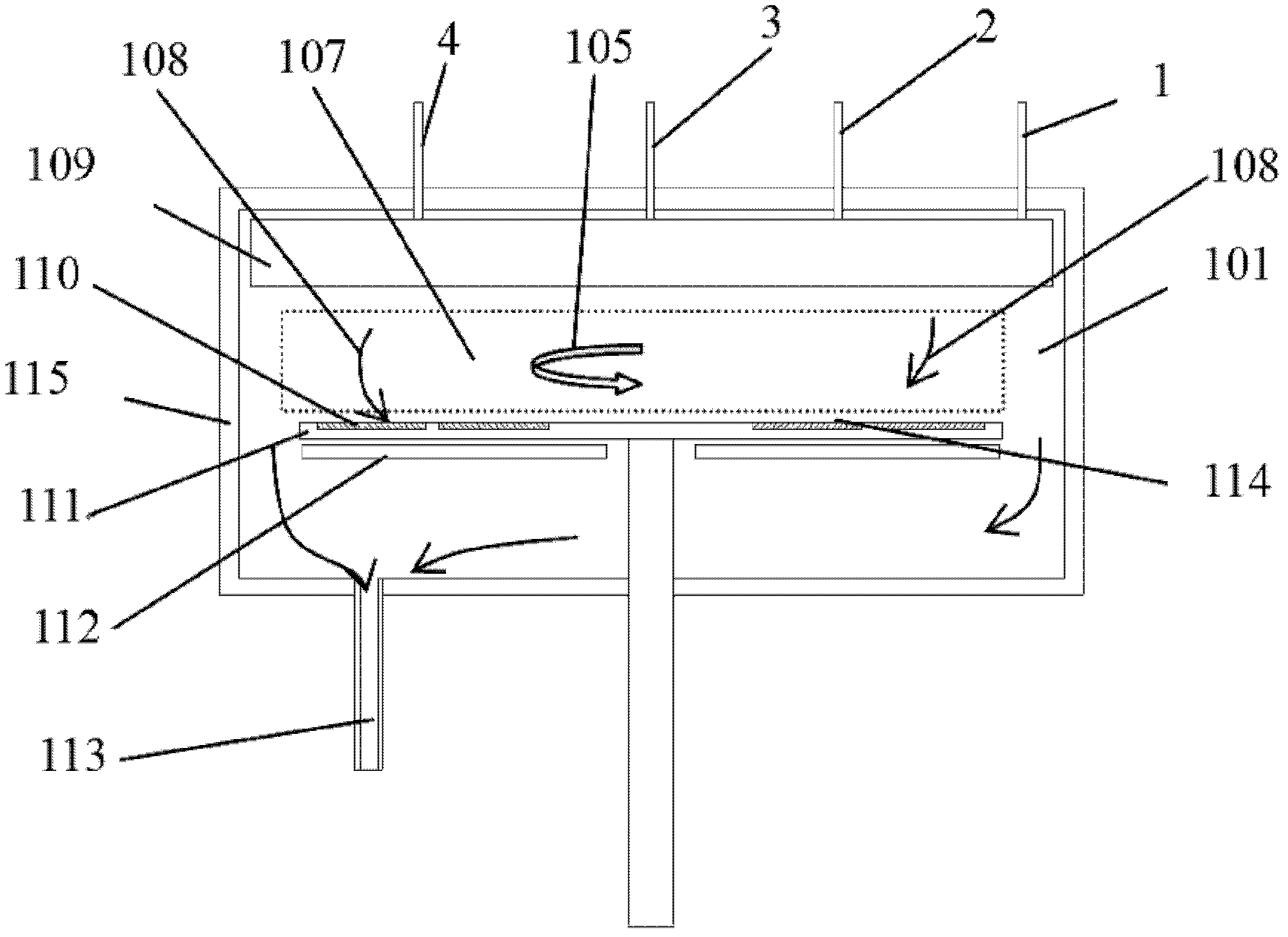

[0037] figure 1Shown is a schematic diagram of an MOCVD reactor 100 employing one embodiment of the present invention. The top of the reactor is gas and cooling liquid inlet ports 1, 2, 3, 4, and its gas port 1 is connected to the second precursor gas supply pipeline, and the second precursor gas is an organic compound containing group III elements such as trimethylgallium Gas; the gas interface 2 is connected to the first precursor gas supply pipeline, and the first precursor gas is a gas containing group V elements such as ammonia; the gas interface 3 is connected to the carrier gas supply pipeline, and the carrier gas is a gas that does not react with the precursor gas , such as nitrogen, hydrogen, etc.; the coolant interface 4 is connected to the cooling system to provide cooling and temperature control for the entire gas shower head. Below the reactor 100 is a reaction tail gas outlet 113 for discharging the waste gas inside the reaction chamber 101 and forming a low pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com