Method for comprehensively recovering valuable elements from high-arsenic-containing copper smelting soot

A technology for copper smelting soot and valuable elements, applied in the direction of improving process efficiency, etc., can solve the problems of complex process, unrecyclable water, low direct yield of valuable metals, etc., and achieves a reasonable process flow, which is beneficial to harmless Chemical treatment, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The main components of typical materials of high-arsenic copper smelting soot are shown in Table 2:

[0037] Chemical composition in table 2 copper soot

[0038] main element

Cu

Zn

Pb

sn

Bi

In

As

Ag

Content (%)

6.04

2.13

30.83

2.78

0.28

285g / t

22.17

0.057

[0039] The arsenic content in the arsenic trioxide accounts for 52% of the total arsenic content.

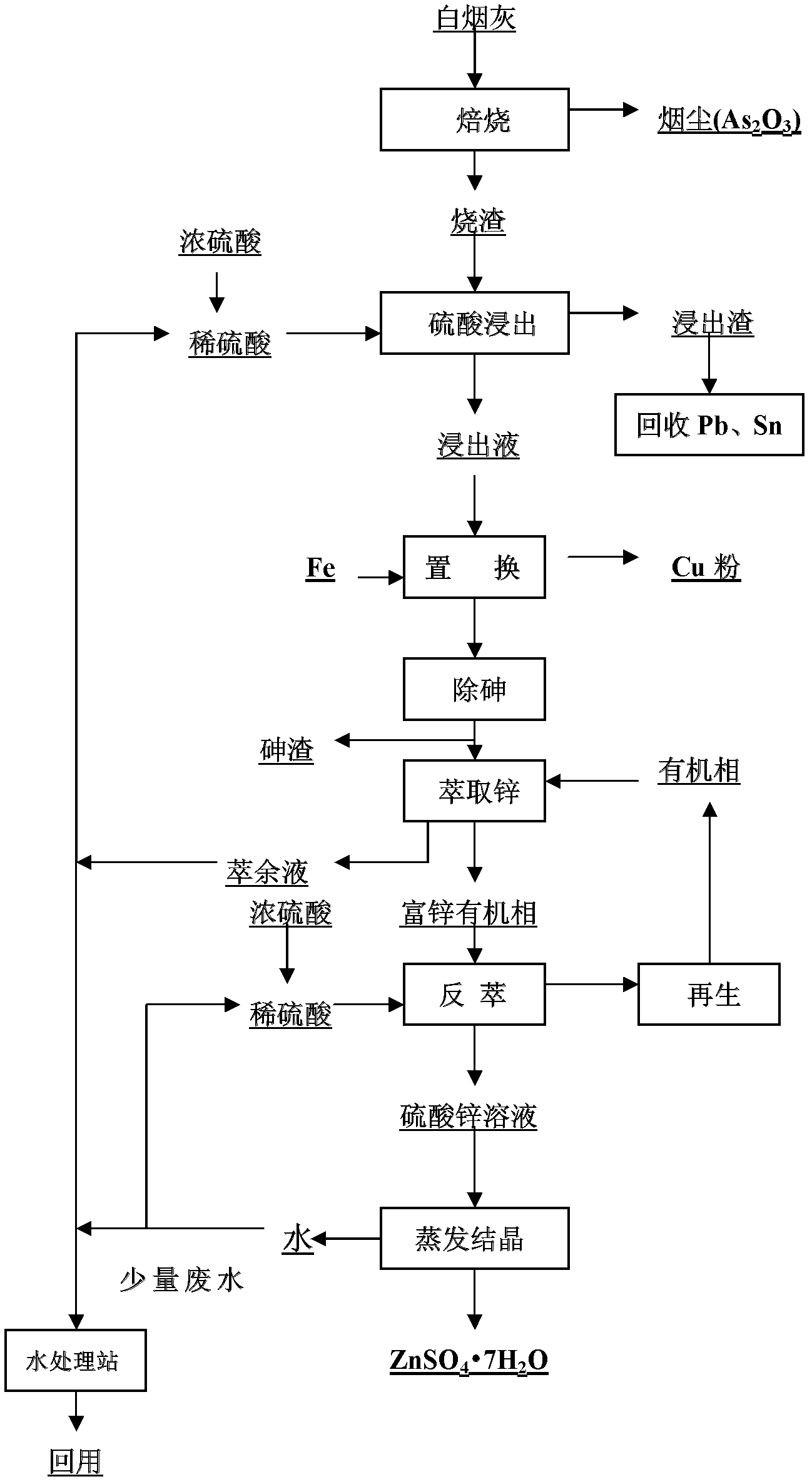

[0040] Take 150kg of soot and roast it with air at 600°C for 2 hours, and collect 51.2kg of arsenic trioxide soot. The slag weighs 104.5kg. Then leaching with 98g / L sulfuric acid, the liquid-solid ratio is 4:1, the leaching temperature is 90°C, and the leaching time is 3h. After stirring and filtering, the leaching solution rich in zinc and copper and rich in lead and tin slag are obtained. Lead-rich and tin slag are sent to recover lead and tin, and zinc-rich and copper solutions are sent to the extraction process a...

Embodiment 2

[0042] Take 150kg of white soot, and roast it by feeding oxygen-enriched air (with an oxygen content of 30%) at 550° C. to collect 50.9 kg of arsenic trioxide dust and 105.6 kg of slag. Then leaching with 147g / L sulfuric acid, the liquid-solid ratio is 4:1, the leaching temperature is 90°C, and the leaching time is 3h. After stirring and filtering, the leaching solution rich in zinc and copper and rich in lead and tin slag are obtained. Lead-rich and tin slag are sent to recover lead and tin. The zinc-rich and copper solution is sent to the extraction process after adding iron powder (excess coefficient is 1.4) to replace copper with P204 (P204: sulfonated kerosene=3:7, water phase : oil phase=2:1 for extraction) to extract zinc, and the raffinate is returned to the leaching process to configure sulfuric acid for leaching. The obtained zinc-rich organic phase is sent to the stripping process, and 98g / L sulfuric acid is used for stripping to obtain a high-zinc solution, and the o...

Embodiment 3

[0044] Take 150kg of white soot, pass it into oxygen-enriched air (oxygen content is 45%) for roasting at 470°C, collect 50.56kg of arsenic trioxide dust and 107.1kg of slag. Then leaching with 98g / L sulfuric acid, the liquid-solid ratio is 4:1, the leaching temperature is 90°C, and the leaching time is 3h. After stirring and filtering, the leaching solution rich in zinc and copper and rich in lead and tin slag are obtained. Lead-rich and tin slag are sent to reclaim lead and tin, and zinc-rich and copper solutions are sent to the extraction process after adding iron powder (excess coefficient is 1.2) to replace copper with P204 (P204: sulfonated kerosene = 3: 7, water phase : oil phase=2:1 for extraction) to extract zinc, and the raffinate is returned to the leaching configuration for leaching with sulfuric acid. The obtained zinc-rich organic phase is sent to the stripping process, and 98g / L sulfuric acid is used for stripping to obtain a high-zinc solution, and the obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com