Production process for synthetizing L-theanine through biological immobilized enzyme catalysis

A production process and biosynthesis technology, applied to biochemical equipment and methods, fixed on/in organic carriers, lyase, etc., can solve the problems of complex operation, high cost, microbial pollution, etc., and achieve process reaction specialization 1. High yield and good purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

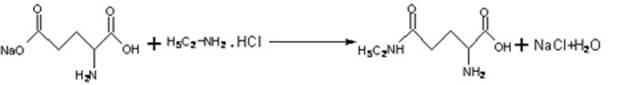

Method used

Image

Examples

Embodiment 1

[0045] Dissolve 16.9g of sodium glutamate, 20.3g of magnesium chloride hexahydrate, 61.1g of sodium hexametaphosphate, 8.54g of ethylamine hydrochloride and 55.1g of disodium adenosine triphosphate in purified water, and adjust the pH to 7.0 with 10% sodium hydroxide solution. Add 100KU solid-phase enzyme and dilute to 5000ml with pure water. (The substrate concentration is 20mmols / L, 20mmols / L, 20mmols / L, 20mmols / L and 20mmols / L) Heated in a water bath, stirred and reacted at 37°C, continuously added 10% sodium hydroxide solution to maintain the pH of the reaction solution =7.0. Samples were taken every 10 minutes to detect the content of sodium glutamate to determine the conversion rate of the reaction; when the conversion rate of L-theanine reached 97%, the reaction solution was separated from the solid-phase enzyme by filtration.

[0046] Slowly flow the filtrate through a strong acidic ion exchange resin (resin equivalent is 1 morl), and then elute with pure water. After...

Embodiment 2

[0050] Dissolve 42.25g of sodium glutamate, 50.75g of magnesium chloride hexahydrate, 152.75g of sodium hexametaphosphate, 21.35g of ethylamine hydrochloride and 137.75g of disodium adenosine triphosphate in purified water, and adjust the pH to 7.0 with 10% sodium hydroxide solution. Add 250KU solid-phase enzyme and dilute to 5000ml with pure water, so that the substrate concentration is 50mmols / L, 50mmols / L, 50mmols / L, 50mmols / L and 50mmols / L respectively. Heat in a water bath, keep stirring at 37°C, and continuously add 10% sodium hydroxide solution to maintain the pH of the reaction solution at 7.0. Samples were taken every 10 minutes to detect the content of sodium glutamate to determine the conversion rate of the reaction; when the conversion rate of L-theanine reached 97%, the reaction solution was separated from the solid-phase enzyme by filtration.

[0051] Slowly flow the filtrate through a strong acidic ion exchange resin (resin equivalent: 2.5mol), and then elute wi...

Embodiment 3

[0055] Dissolve 84.5g of sodium glutamate, 101.5g of magnesium chloride hexahydrate, 305.5g of sodium hexametaphosphate, 242.7g of ethylamine hydrochloride and 275.5g of disodium adenosine triphosphate in purified water, and adjust the pH to 7.0 with 10% sodium hydroxide solution. Add 500KU solid-phase enzyme and dilute to 5000ml with pure water, so that the substrate concentration is 0.1mols / L, 0.1mols / L, 0.1mols / L, 0.1mols / L and 0.1mols / L. Heat in a water bath, keep stirring at 37°C, and continuously add 10% sodium hydroxide solution to maintain the pH of the reaction solution at 7.0. Samples were taken every 10 minutes to detect the content of sodium glutamate to determine the conversion rate of the reaction; when the conversion rate of L-theanine reached 97%, the reaction solution was separated from the solid-phase enzyme by filtration.

[0056] Slowly flow the filtrate through a strong acidic ion exchange resin (resin equivalent: 5.0mol), and then elute with pure water un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com