A self-heating straw carbonization furnace

A straw carbonization and self-heating technology, which is applied in fixed carbonization furnaces, coke ovens, special forms of dry distillation, etc., can solve the problems of large fuel consumption and combustible components are not discharged for utilization, etc., to reduce fuel consumption and cycle energy utilization High efficiency and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

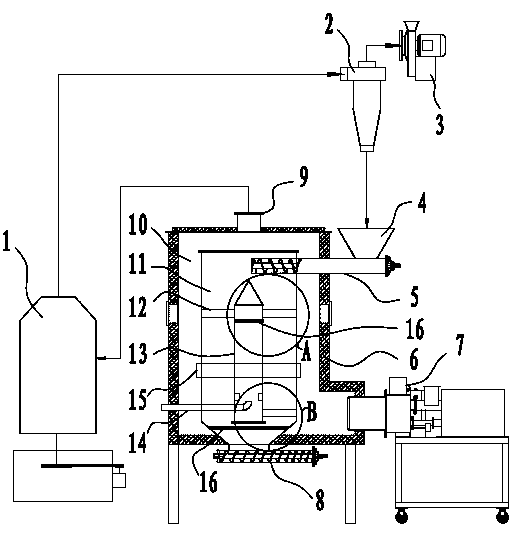

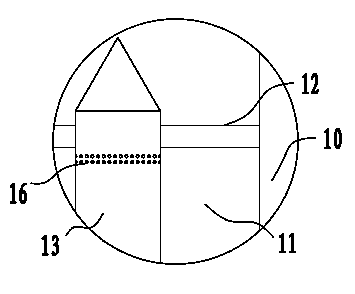

[0021] Embodiment: a kind of self-heating straw carbonization furnace, such as figure 1 , figure 2 , image 3 shown. The device includes a cylindrical carbonization chamber 11, an inner combustion chamber 13 is arranged in the middle of the carbonization chamber 11, an outer combustion chamber 10 is surrounded on the outer side of the carbonization chamber 11, and a heat insulation layer 6 is arranged on the outer side of the outer combustion chamber 10, and the carbonization chamber is interposed Between the inner combustion chamber and the outer combustion chamber, and fixed by the fixing frame 15. The top of the carbonization chamber 11 is provided with a feed auger 5 , the front end of the feed auger 5 is provided with a feed hopper 4 , and the bottom of the carbonization chamber 11 is provided with a discharge auger 8 . Such as image 3 As shown, the bottom of the carbonization chamber 11 is provided with two rows of smoke exhaust holes 16 on the side wall adjacent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com