Complex adhesive and preparation method thereof

A compound adhesive and compound emulsifier technology, applied in the direction of adhesive, adhesive type, ester copolymer adhesive, etc., can solve the problems of insufficient bonding strength, poor folding resistance, poor flatness, etc., and achieve easy film formation. , Excellent adhesion, good dry film flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

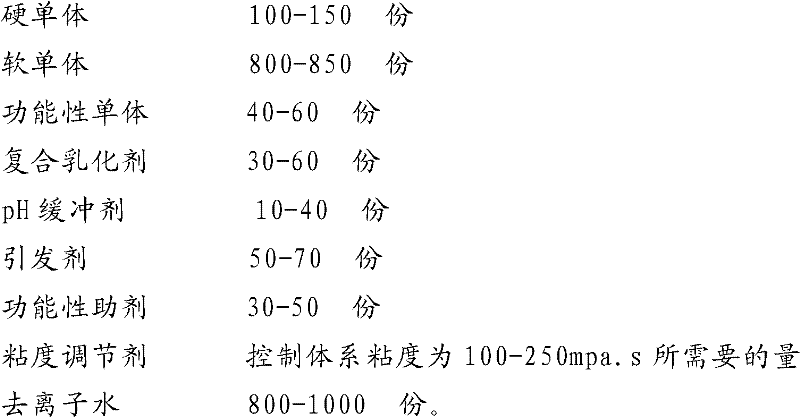

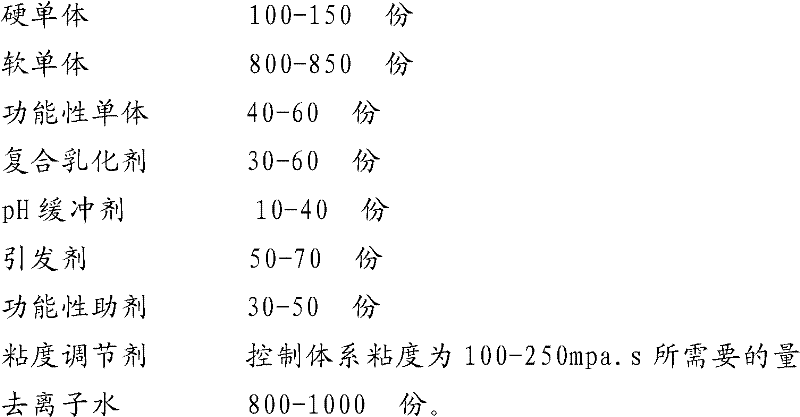

Method used

Image

Examples

Embodiment 1

[0034] With the deionized water of 340 parts by weight, the composite emulsifier of 18 parts by weight (the phenol ether sulfate of 15.6 parts by weight and the alkylphenol polyoxyethylene ether of 2.4 parts by weight), the acrylic acid of 30 parts by weight, the acrylic acid of 20 parts by weight Hydroxyethyl ester, the butyl acrylate of 800 weight parts, the styrene of 150 weight parts join in the pre-emulsification tank and stir (rotating speed is 650rpm) 30 minutes, after being made into pre-emulsion, take by weighing the pre-emulsion of 203.7 weight parts as The bottom seed reaction solution is for use;

[0035] With the deionized water of 500 parts by weight, the buffering agent (ammonium bicarbonate) of 22 parts by weight, the compound emulsifier (the phenol ether sulfate of 15.6 parts by weight and the alkylphenol polyoxyethylene ether of 2.4 parts by weight) of 18 parts by weight Add in the polymerization reactor and heat up to 86~88 ℃, drop into 203.7 parts by weight...

Embodiment 2

[0040] With the deionized water of 340 parts by weight, the composite emulsifier of 18 parts by weight (the phenol ether sulfate of 15.6 parts by weight and the alkylphenol polyoxyethylene ether of 2.4 parts by weight), the acrylic acid of 30 parts by weight, the acrylic acid of 20 parts by weight Hydroxyethyl ester, the butyl acrylate of 850 weight parts, the methyl methacrylate of 100 weight parts join in the pre-emulsification tank and stir (rotating speed is 650rpm) 30 minutes, after being made into pre-emulsion, weigh 203.7 weight parts of pre-emulsification The emulsion is used as the bottom seed reaction solution for subsequent use;

[0041] With the deionized water of 500 parts by weight, the buffering agent (sodium bicarbonate) of 22 parts by weight, the compound emulsifier (the phenol ether sulfate of 15.6 parts by weight and the alkylphenol polyoxyethylene ether of 2.4 parts by weight) of 18 parts by weight Add to the reaction kettle and heat up to 86-88°C, drop 203...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com